description of the processes involved in extracting iron from the iron ore

:: : Projects Reports

Mining and Ore Processing Mercury Pollution. Estimated Population at Risk: Million. Description. Mining and ore processing occurs throughout the world and consists of extracting minerals, metals, and gems from surrounding earth and ore. Industrial mines vary in size, with some being quite small operations and others very large.

GCSE CHEMISTRY Extraction of Iron Haematite ...

Extraction of Iron. Iron is extracted from its ore in the blast furnace. The main iron ore is called haematite. Haematite is iron(III) oxide Fe2O3. The iron ore contains impurities, mainly silica (silicon dioxide). in the blast furnace. The calcium silicate (called slag) floats on the liquid iron.

Aluminium production process

ALUMINA PRODUCTION. Bauxite is crushed, dried and ground in special mills where it is mixed with a small amount of water. This process produces a thick paste that is collected in special containers and heated with steam to remove most of the silicon present in bauxites. The ore is loaded into autoclaves and treated with lime–caustic soda.

Extraction of Zinc from Zinc Blende Reference Notes

Galvanization. The process is used for galvanization of small iron articles like nail, screws etc. In this process iron article are mixed with zinc dust and then heated in enclosed vessel for few hours when coat of zinc is applied on iron.

GCSE CHEMISTRY Extraction of Iron in the Blast Furnace ...

Extraction of Metals. Extraction of Iron.. Chemistry of the blast furnace ().. Limestone is calcium carbonate (CaCO 3) and it is added to the blast furnace to remove the impurities in the iron ore. Calcium carbonate is decomposed by heat in the furnace to give calcium oxide and carbon dioxide. This is called thermal decomposition (see examples of other carbonates). ...

Gold Processing Methods Gold Ore Extraction

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery ...

Ferritin, the IronStorage Protein

Ferritin is a protein that stores iron and releases it in a controlled fashion. Hence, the body has a "buffer" against iron deficiency (if the blood has too little iron, ferritin can release more) and, to a lesser extent, iron overload (if the blood and tissues of the body have too much iron, ferritin can help to store the excess iron).

Largest Iron Ore Producers in the World in 2017 | Mining ...

NDMC is Indian mining company owned by Indian Government founded in 1958. It is India's biggest iron ore producer and one of the biggest iron ore producers in the world as well. Apart from iron ore business, they also extract copper, limestone, dolomite, bentonite, diamonds, etc., which are being extracted from four mines in India. 4.

Mineral Resources Flashcards | Quizlet

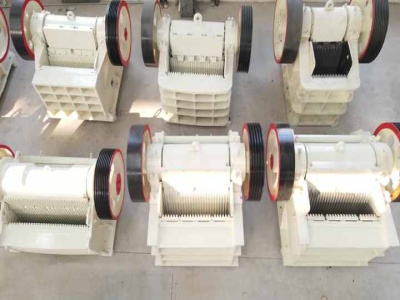

One of the first stages in mineral processing is crushing the ore to seperate ore minerals from gangue, producing finegrained waste called tailings or slimes. Tailings not only contain toxic metals but also harmful chemicals used in the extraction process. Uranium tailings are a particular hazard because they are radioactive.

How copper is made material, used, processing, steps ...

In addition to the ores themselves, several other chemicals are often used to process and refine copper. These include sulfuric acid, oxygen, iron, silica, and various organic compounds, depending on the process used. The Manufacturing Process The process of extracting copper from copper ore varies according to the type of ore and the desired ...

Stages Of Metal Extraction From An Ore

The main process or stages involved in the extraction of metal from their ores are: (a)Ore purification (b) Extraction of the metal (c) ... a given metal ore depends ... Read more stages of metal extraction from an ore Mining Equipment ...

THE BLAST FURNACE IRON PRODUCTION

As the mixture of iron ore, coke and limestone heats, the hot waste gases are collected and cleansed. They are then used to help heat the air blast, required if blast furnace is to reach the high temperatures needed to produce molten iron. The stock level is constantly 'topped up'.

Iron Ore: Sedimentary Rock Pictures, Definition More

The primary use of iron ore is in the production of iron. Most of the iron produced is then used to make steel. Steel is used to make automobiles, locomotives, ships, beams used in buildings, furniture, paper clips, tools, reinforcing rods for concrete, bicycles, and thousands of other items. It is the mostused metal by both tonnage and purpose.

Extraction Of Metals SlideShare

Mar 03, 2009· Extraction of metals Only some unreactive metals such as silver, gold and platinum can occur freely in nature. Most metals react with other elements to form o. Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising.

Solved: Extraction Of Metals Using The Above Summary For T ...

Extraction of Metals Using the above summary for the extraction of iron, rank the common steps involved in the process of extraction of iron from its ore Rank the steps from first to last. To rank items as equivalent, overlap them.

The Emergence of Iron Smelting and Blacksmithing: 900 B. C ...

The Emergence of Iron Smelting and Blacksmithing: 900 B. C. to the Early Roman Empire. The technology required to separate iron from its ores and convert it into durable and useful objects is far more complicated than that needed to work successfully with copper and bronze.

Notes on Extraction Of Metals: Metallurgy | Grade 11 ...

The process of extracting a metal in pure form from its ore is known as metallurgy. The process of treatment depends on upon the nature of the ore, impurities, and the metal. From the extraction point of view, the metals can be broadly classified into five categories.

Natural Sciences Grade 9

Extraction of iron. The first iron mining techniques used charcoal which was mixed with iron ore in a bloomery. When heating the mixture and blowing air (oxygen) in through bellows, the iron ore is converted to the metal, iron. The chemical reaction between iron oxide and carbon is used here to produce iron metal.

EXTRACTION OF METALS METALLURGY | Chemistry .

The process of extracting pure metal from its ore is known as metallurgy. . Since, the nature of the ore and also the properties of different metals are different, therefore, it is not possible to have the universal scheme which may be applicable to all the metals.

3 Technologies in Exploration, Mining, and Processing ...

Technologies in Exploration, Mining, and Processing INTRODUCTION The life cycle of mining begins with exploration, continues through production, and ends with closure and postmining land use.

Latest Posts

- مسحوق طحن النباتات في انكلترا

- التعدين المحجر اليمن خطة عمل

- خطة عمل محجر الحجر الجيري

- أبحث عن آلة كسارة في ليبيا

- أكبر كسارة المطرقة

- المشترين لتنتالايت في الصين والمملكة العربية السعودية

- المحمولة استئجار محطم ملموسة في شيكاغو

- خلفيات سطح المكتب آلة محطم

- أبحث عن كسارة متنقلة أو كسارة فكية في سو

- محجر الرخام الأبيض في مصر

- كسارة المطرقة العكسية بسعة عالية

- قدم 300 كسارة مخروطية

- محطم عملية الكربون المنشط

- كسارة مخروطية للبيع تركيا

- مجاميع صخور البازلت وشركة التعدين

- awesome of sample business plan brick making simple frugal

- crushing dolomite to mesh

- pp raffia bag grinder granulator machine taiwan

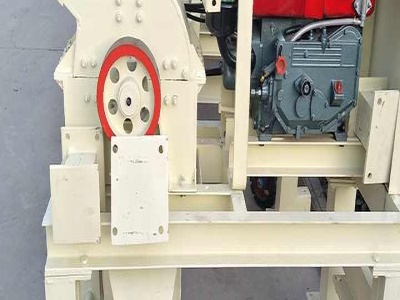

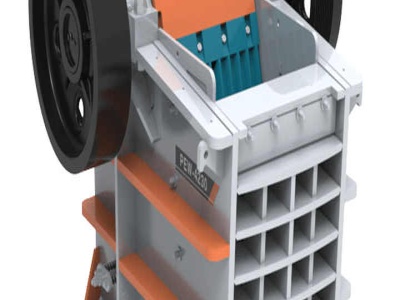

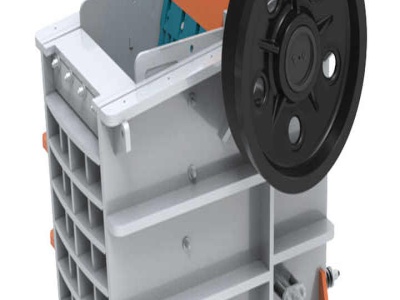

- jaw crusher type pe 900x600mm

- iron properties llc coal mine

- pettibone universal jaw crusher 30 x 42

- aggregate crusher washing

- belt20 conveyor

- alunite iron ore in limestone quarries

- harga penghancur batu di afrika selatan

- how to smooth a concrete wall finish home guides sf gate

- gold miner players english

- machines to tempel sand on drivers

- sale russia crushere

- how to design parameters for a ball mill