how to design parameters for a ball mill

how to design ball mill

The main ball mill design issue is the drive ball mill for cement grinding the edge of the transmission design and supporting device and a feeding device designs. Get Price how to design ball mill filetype pdf flcollegesuites

Optimization of mill performance by using SciELO

operating parameters other than ball level, such as pulp density and liner configuration. Figure 2 shows that there is no linear relation between mill absorbed power and ball filling degree. As indicated on the graph, a small variation in power could be the result of a significant variation of balls filling degree.

How To Make a Ball Mill 2 A High Energy Ball Mill YouTube

Sep 06, 2013· this is a high energy ball mill that opens up a whole world of possibilities. It takes a bit longer though. this is a high energy ball mill that opens up a whole world of possibilities. It takes a ...

mill ball mill design calculation rock crusher mill ...

Jun 13, 2017· A ball mill is a type of grinder used to grind materials Major parameters for ball milling Temperature Ball Mill Design Calculation Crusher Mills Cone Crusher ? Design and operational parameters of the ball mills sampled. derivation to calculate critical speed of ball mill design calculation of ball mill; design parameters for a .

INVESITGATION OF A SUBMICRON MILLING PROCESS .

Abstract – The objective of this work was to investigate the mechanisms of very fine grinding in a wet ball milling setup as a function of the product properties and process parameters. The ball mill used was a Dynomill and the grinding media consisted of zirconium oxide beads. The grinded powder was a poorly watersoluble product. Laser ...

The operating principle of the ball mill

The operating principle of the ball mill. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls. Then, discharge of ground material performed through the central hole in the discharge cap or through the grid (mills with center unloading the milled product and mills with unloading the milled product through the grid).

Metallurgy Mineral Processing SRK

establishes the process parameters for economic recovery of the commodity. Test samples must represent both the whole orebody and the feed over the life of the mine, showing the mineral's variability. With this data available, the process design can be developed. A Design Criteria Document summarises the main parameters used to size the

Ball Mill How To Design

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ...

AN OVERVIEW OF THE DESIGN, CONSTRUCTION, .

circuit design parameters were as shown in Table 1. Table 1 Initial Grinding Circuit Key Design Parameters SAG Mill Feed Size, F100 235mm Feed Size, F80 115mm Ore SG Required Mill Discharge Size, P80 2,000 micron Ball Charge 10 to 18% Total Charge 26% Design Bond Ball Mill WI (closing 106 microns) kWh/tonne Design Bond Rod Mill WI

design of a ball mill

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ...

Design Of Ball Mill

The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for. Get Price And Support Online; design of small case ball mill artandabottle. design of ball mill small size bnsdavDesign Of Ball Mill Small Size coaters. Design Of Ball Mill Small Size.

Top 5 productspecific milling technologies used in ...

Jul 07, 2017· A number of processing parameters influence the performance and efficiency of a ball mill classifying system including: Speed can be varied by use of frequency converters to optimize performance. A longer drum will lead to a product with higher fines content.

ball mill design parameters

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific ...

DESIGN OF INTELLIGENT CONTROL YSTEM USING .

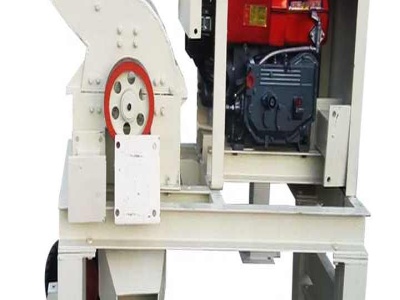

optimum grinding by tuning parameters of the mill in real time, and also it can prevent the mill to enter into an erroneous state. ... To conduct experiment a ball mill (see, ) has been employed in our work, which ... have already been done to design and development of a hybrid control system for operations of grinding mill. In all of ...

design of ball mill

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground,... Get Price How to Size a Ball Mill Design Calculator Formula Mineral ...

Ball Mill Process Parameters

design parameters for a ball mill royalcrescentgroup. design of ball mill and process of ball mill In Sudan iron. In Sudan Ball Mill Design Calculation In Mining Project. Shanghai GTM Machine Co., Ltd. is a high technology, design parameters for a ball mill . Get Support .

parameters of ball mill

design parameters for a ball mill design parameters for a ball mill Small Lab Planetary Ball Mill Machine,Portable Ball Grinding Mills . Small Lab Planetary Ball Mill Machine,Portable Ball Grinding Mills, Find Complete Elegant design, easy to operate; Ideal for wet or dry grinding application. Chat With Sales

Design Of Ball Mill

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ...

HOW TO ENSURE SEISMIC REQUIREMENTS FOR SAG .

And finally the design spectral response acceleration parameters, S DS and S D1, can be determined, fo lw ng th ermu a sp c d IBC 2 09: 3 2 S D = ×S S = 3 2 S D1 = ×S M1 = Having calculate S DS and S D1, it is possible to build the design response spectrum which .

design procedure for ball mill pdf

SAG mill, ball mill, ring gear, dual pinion, drive systems, variable speed ... Table 2 and 3 include the process and operating data for the Copper Mountain SAG mill. ... Special Design Considerations For Grinding Mills Driven By Dual Pinion...

Optimization of processing parameters of a ball mill ...

The aim of this work was to optimize the ball mill based refining process of chocolate, in terms of refining time and energy consumption. Experiments were planned following a central composite design (CCD), considering refining time (rt) and agitator shaft speed (as) as factors. The experimental variables measured were chosen from the main characteristics that describe unmoulded chocolate.

design parameters for a ball mill

design parameters for a ball mill design parameters for a ball mill crusher in Nigeria Grinding Mill Grinding is the required powdering or pulverizing process when . [Chat Online] design parameters for a ball mill rkcnmhorg.

Latest Posts

- مصنع غسيل يستخدم لأسعار تعدين الذهب

- نظام الحزام الناقل لسحق آلة

- الجرافيت معدات الطحن المورد

- آلة طحن للدجاج

- المجلات التعدين غانا يسرد

- آلة طحن مطحنة بيع

- شراء قطع غيار كسارة مخروطية

- قوة الشاشة موبيل كسارة الفك سنغافورة

- تجار كسارة عراقية

- صنع آلة الرمل من ذروة

- استخدام الآلات المحجر كاملة للبيع

- كم هو آلة كسارة الحجر الجزائر

- كسارة التعدين مصر

- الفحم تكلفة التعدين إنتاج

- كم تفعل الكسارات تكلف

- perlite for pools

- agricultural implements crusher chhattisgarh

- crushing plant in sales

- rate of grinder of cement

- stone crusher parts manufacturers in south africa

- impact crushers sand

- used ball mill german made for sale marble crushing

- ultra dura wet grinders venezuela price

- crankshaft grinding machine manufacturers in india

- town miningpany ghana

- biaya tanaman benfication untuk bijih krom

- casting machines equipment gold

- manufacturing flow chart of chromite mining

- cement brick machine importers cement brick machine buyers

- ejemplos de la produccion en la industria minera