why pfister is used for coal mill

Feeding and dosing alternative fuels I FL

The PFISTER® TRWS/D is designed to handle fuel material densities from t/m³ to t/m³ with the same machine, giving you maximum flexibility. High feeding accuracy Stable kiln operation and complete combustion – that's what you want to achieve with your alternative fuels.

How Is Coal Crushed In A Mill

How Is Coal Crushed In A Mill; why coal is crushed in power plant – Grinding Mill China. The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products.

how to remove debris from a coal pfister feeder

how to remove debris from a coal pfister feeder , how to remove debris from a coal pfister feeder Why Coal Mill Use Pfister » pfister feeder coal handling problems Why do people try and use big words when there is . >>Chat Online; the different between coal and iron ore pellets Cutter Bits.

Rotor weighfeeder for dosing crushed coal I FL

The PFISTER® TRWK rotor weighfeeder for crushed coal uses advanced weighing electronics to ensure accurate dosing that reacts to changes in the feed. The equipment is robust and wearresistant, making the complete system extremely reliable.

How is Steel Produced? | World Coal Association

Around 150 kg of coal are used to produce 1 tonne of steel in electric arc furnaces. Other steel production methods Pulverised coal injection. Pulverised Coal Injection (PCI) technology involves injecting coal directly into the blast furnace to provide the carbon for ironmaking – displacing some of the coke required for the process.

why vfd in coal mills

Rod mills are used to crush the coal used in our gasification process. ... voltage waveforms of the VFD output were analyzed, we also discovered one of the VFD...

parts of a coal mill

Pfister Parts In Coal Mill why coal mill use pfister rrbresultgovcoinMuhammad ijaz Mian | LinkedIn Erection and commissioning of Coal Mill including Pfister . READ MORE coal mill ntpc singrauli and coal mill .

pfister feeder o amp m manual

O m Manual for coal ball bowl mill ... why coal mill use coal grinding can be used grinding machinery such as the vertical mill, ...

Mining Industry: What is a coal mill? Quora

Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in cement plant for bo...

Emergency inerting systems for coalgrinding applications

Oct 21, 2011· In the case of coalgrinding or storage (as one might find in a cement plant) it is not possible to remove the fuel (coal) or ignition source (grinding energy, heat, static charges) and so one has to concentrate on removing the third necessary component O 2. This fact has given rise to inerting systems that rely on the use of inert gases.

What Is Used Of Iron Orewhat Is Used To Crush Xoal

what equipment is used to generate coal mill or . Sometimes, within underground mining, coal crusher can also be used to crush big fossil fuel into smaller then transport all of them by belt conveyor.

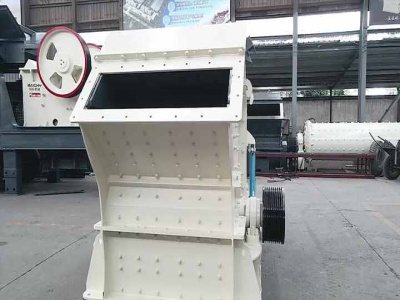

Crushing Plants In Californiya Grinder Coke

why coal mill use pfister Coal / Lignite Handling Plant at Power Plant End Crushing Screening Plants. MBE has successfully built on turnkey basis over 20 Crushing and Screening Plants for . Chat Now why coal mill use pfister Coal / Lignite Handling Plant at Power Plant End Crushing Screening Plants.

Coal mill pulverizer in thermal power plants SlideShare

Nov 17, 2012· Coal mill pulverizer in thermal power plants. At Wisconsin Electric Power Company, the use of pulverized coal was also shown to be a viable fuel for electrical power production after World War I Pulverized coal burns like gas, can be easily lighted and controlled.

how to calculate coal mill capacity for cement plant

Coal mill. 650. Cement mill 1. 4700. Cement mill 2. 3050. Packing plant. 350. Get Price. Cement mill Wikipedia. ... Pfister® feeding and dosing devices exemplary in the cement production process: ... rate and the measured bulk material mass to calculate the .... Dosing capacity: Up to 50 t/h with only one system possible.

Coal mill and motor

Longlasting coal mill for efficient grinding | FL The coal mill can also grind petroleum coke and anthracite down to a fineness below 5% +90 micromillimeters (mm) when coupled with a variable speed mill motor. No sticky situations The ATOX® Coal Mill can grind and dry raw coal .

Why coal mill use pfister

why coal mill use pfister oklahoma department of mines. the hartshorne coal commonly is split into two the iron post coal . More Info > Live Chat; why use ball mill in cement . why coal mill use pfister india,stone crusher . your location mining equipments > why coal mill use pfister. crusher. . tube ball mill used for cement and . More Info ...

what is coal mill of a cement industry

Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in cement plant for both drying and grinding of the powders.

Pulverizer Wikipedia

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plants.

coal mill co2 system

PE series jaw crusher is usually used as primary crusher in quarry production lines, mineral ore crushing plants and powder. PEW Jaw Crusher PEW series Jaw crusher features big crushing ratio, reliable operation, easy maintenance and low operating cost.

coal pulverizer grinding mill

Coal mills is major equipment of cement plant and used for drying and grinding coal. coal mill pulverizer drawing, vsi crusher for sale Coal Mill... Chat Now Umatech Micron Manufacturer of Raymond Mill .

why co utilized in coal mill

PAMC is a highly professional Horizontal Boring Machine,Grinding Mill,Crusher also offers why co utilized in coal mill, screening attachments, drum cutters and grapples. In addition, the company has magnetic separators and dust suppression kits for .

Mining Industry: What is a coal mill? Quora

Air swept coal mill is the main equipment in cement plant for both drying and grinding of the powders. Compared with the ordinary ball mill, it has advantages of higher capacity, more convenient operation, safer usage, and more reliable performance. Coal mill is used to grind, pulverize and dry coal before the coal is transmitted the boiler.

Latest Posts

- توفير الطاقة الكرة الطواحين

- آلة مطحنة الكرة للبيع في دبي

- أفضل كسارة شركة تصنيع في الصين

- عملية سحق خام ما يسمى

- من الحجر الجيري المحمولة كسارة في المملكة العربية السعودية

- قطع الغيار مصنع كسارة في السودان

- الميكا مسحوق طحن آلة المورد

- تكلفة مشروع مصنع للاسمنت مصغرة معالجة

- المخطط العام لمحطة الفحص

- مصنع الفحم النحاسي في مصر

- صناعة تكسير الحجر الأملس في الأردن

- موردي كسارات الحجر الجيري في مصر

- سحق تجار مصنع في السعودية

- كسارات ركام في عمان

- المورد آلة concasseur في الصين

- horno rotatorio cemento

- zambia rock crusher machinery

- ball mill grinding process images

- zd shaker introduction

- carp industries carp industries

- hp cone crusher for sale stone crusher machine

- how to do pricing calculations for granite quarry land in india

- high quality mobile impact crusher rock impact crusher price

- conventional wet grinder motors

- copper ore ultrafine grinding mill manufacturer

- 100 ton mobile crucher poduct russian

- hydraulics system for cone crusher dubai

- impact crusher manufacturers impact crusher manufacturers suppliers and

- material conveying belt conveyor machine for stone jaw crusher

- www hewey used machinery in bangalore