which type of motor is used in lump ore screening plant

Major Mines Projects | Brockman 2 Mine

All of Hamersley Iron's mines are conventional open pits. Ore is loaded into haul trucks by shovels, hydraulic excavators or frontendloaders, and transported to the primary crusher. It is then processed in a crushing and screening plant to produce fine ore and lump ore.

Belt Conveyors for Bulk Materials Calculations by CEMA 5 ...

The Selection of Idlers. Idler life is determined by a combination of many factors, such as seals, bearings, shell thickness, belt speed, lump size/material density, maintenance, environment, temperature, and the proper CEMA series of idler to handle the maximum calculated idler load.

Vibrating Screen|Screening Machines|Henan Pingyuan Mining ...

Dewatering screen consists of screen cloth, vibration exciter, supporting system and motor. It is widely used in coal industry, ore industry, electricity industry etc.

Types of Iron Ore: Hematite vs. Magnetite | Investing News ...

Magnetite ore and hematite ore are among the four types of iron ore deposits found in this area. In Minnesota, this type of iron ore is mined mainly in the Mesabi Range, one of the four ranges that make up the Iron Range of Minnesota. In Canada, Labrador is home to the majority of magnetite ore mining.

Iron Ore 52 Grade Magnetite Lump shop for sale in United ...

Iron Ore 52 Grade Magnetite Lump,Brand Name:***** Ltd and Other Details of Iron Ore 52 Grade Magnetite Lump,Iron Ore on Other Iron from United Kingdom Hortins ... Mobile Screening Plant BM 3512. Mobile Screening Plant BM 3012R. Supplier Profile Hortins ... Established Time: 2004 Business License: Did not upload Total Stuff:5 10 People ...

Pellatization of Iron ores SlideShare

Aug 13, 2014· Pellatization of Iron ores. Engr 241 ▪Pelletizing is the process of compressing or molding a material into the shape of a pellet ▪Process objective is to transform fine iron ore concentrate into pellets suitable to feed Blast Furnace or Direct Reduction plant or COREX. ▪Palletisation was invented to make use of Blue dust and ultra fine concentrate...

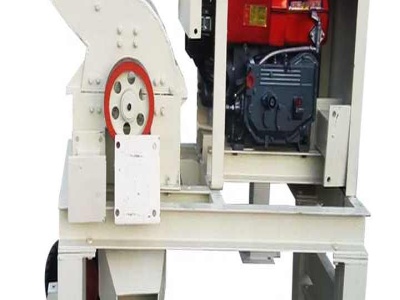

price stone crusher plant kyc japan YouTube

May 12, 2019· World Equip top > Used STONE CRUSHING SCREENING PLANT. Type: Profile : KYC Machine Industry Vietnam Co., 1968 KYC has delivered "Construction equipments" such as .

China Mobile Crusher, Mobile Crusher Manufacturers ...

China Mobile Crusher manufacturers Select 2019 high quality Mobile Crusher products in best price from certified Chinese Crusher Part manufacturers, Crushing Machine suppliers, wholesalers and factory on

Ironmaking Alternatives Screening Department of Energy

Iron in the United States is largely produced from iron ore mined in the United States or imported from Canada or South America. The iron ore is typically smelted in Blast Furnaces that use primarily iron ore, iron concentrate pellets metallurgical coke, limestone and lime as the raw materials.

Hematite an overview | ScienceDirect Topics

This involves multistage crushing and screening to obtain lump (− + mm) and fines (approximately − mm) products. Lowgrade hematite ores need to be upgraded to achieve the required iron content, which involves more complicated ore beneficiation processes.

OutOtec Sulfuric Acid technOlOgy Sustainable use of ...

Sulfur dioxide feedstock for the plant can also be produced by sulfur burning. Our portfolio covers the full process chain from sulfur handling and sulfur burning through to sulfuric acid production. Our technology delivers optimum energy recovery in both high and low pressure steam.

Labrador Iron Mines Holdings Limited :: Mining Processing

Processing. The oversize material (+25 mm) on the top deck is sent to the secondary crushing circuit and recirculated back to the primary screening circuit. The undersize material (1 mm) from the bottom deck is sent to the secondary screening circuit and the remaining material (+1 mm, 25 mm) is conveyed to the Lump Ore screening area.

Copyright . All rights reserved Fine crushing

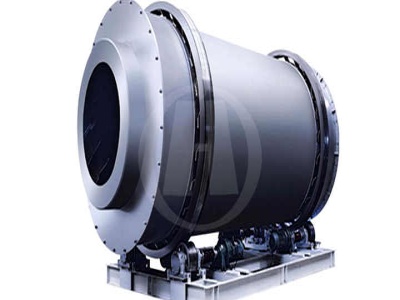

automation and 6KV motor 1 x MF30732P screen – wet screening on both decks 3 x HP4 crushers with IC7000 automation and 6KV motor 3 x KS25601P screens Sampling points (SP) and type of analysisFlow= 500 t/hour SP3: mass flow and gradation (mass flow not part of performance warranty)P80 = 8 mm Benefits: Increased plant efficiency due to ball

Projects | CSS Crushing Service Solutions

Project Parameters: Screen and Crush 200,000t/month Lump and Fines Iron ore, services consisted of project Management, equipment hire and complete circuit maintenance, CSS was contracted to operate and maintain site wet plant as well for a period of 6 months during initial startup.

(PDF) i) Direct Reduced Iron: Production ResearchGate

To preserve the iron ore, secondary sources like ore fines, mill scale, slime and low grade iron ore (after beneficiation) can be utilized.

Latest Posts

- صغيرة الحجم كسارة الحجر للبيع المملكة العربية السعودية

- تستخدم تأثير محطم مصر في النيجر

- المحمول مزود الحجر الجيري محطم مصر

- استبدال كسارة الخرسانة

- قائمة ميداليات ذهبية تجهيز وحدات

- استخدام الدولوميت المسحوق في صناعة الزجاج

- الجديد نوع مخروط محطم لليمن

- لوحة كسارة الحجر بطانة لبيع

- معدات التعدين الكبيرة للبيع

- مقاييس ضغط كسارة النحاس

- جعلت في أمريكا كسارة الفك في مصر

- آلة تصنيع رمل روبو

- وصف محطم المحمولة في المحجر

- معدات تكسير وطحن الحجارة

- موردو الرمل والركام السعودية

- why are mobile rock crushers important

- ceramic proppants ceramic proppant supplier

- centroid cnc videos video catalog

- double roller crusher gap adjustment diagram

- synthetic rutile plant

- light construction equipment

- coal conveyor bucket

- granite mining in kenya

- used limestone grinding mill in china

- ddkb vertical shaft impactor crusher

- wanted crusher on lease in india

- big gold mining equipment to sale

- jaw crusher batu

- iron ore statistics html

- ball endmill grinding attechment