what is use of preheater in cement plant

Preheater and Calciner A TEC Innovative Technologies ...

The core of the pyroprocess of each modern cement kiln is the preheater. Most substantial thermochemical reactions of the cement process occur in the riser ducts and in the calciner(s) and certainly in the sintering zone of the kiln. Modern suspension preheater kilns usually have 1 or 2, in a few cases also 3 strings with 4 or 5 stages.

Energy Consumption Benchmark Guide: Cement Clinker .

The focus of this Guide is on energy used in the production of cement clinker; unlike finished cement, all plants produce clinker. Most of the energy information in this report was provided by the Cement Association of Canada (formerly known as the Portland Cement Association of Canada).

Portland Cement Manufacturing US EPA

portland cement has lower iron and manganese contents than gray portland cement and is used primarily for decorative purposes. Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement. The sixdigit Source

cement preheater kiln burner

Preheater Kiln Wear Parts for Cement Plants , Reduce your cost per ton with engineered preheater and kiln wear parts by Columbia Steel Parts include thimbles, inlet trays, nose ring segments, more. Live Chat; CFD MODELING OF A CEMENT KILN WITH MULTI,

Formation and Techniques for Control of Sulfur Dioxide .

Sulfur in cement kilns is derived from both kiln feed and kiln fuel. The form of the sulfur dictates the location in the kiln where the SO2 generation takes place. Sulfur in the fuel is oxidized in the burning zone or calciner, and is easily removed by reactive lime present in the kiln.

A case study of hightemperature corrosion in rotary ...

five preheater stages, the attack occurred primarily from sulphates that probably originated in the raw feed and fuel being used in the plant and that penetrated the refractory lining. The corrosion was similar to ashdeposit corrosion often observed in steam boilers. In the second case the plant consisted of a long dry kiln with a single

Cement Production: Raw Meal Production in Steps

Pneumatic Conveying technology can also be used for the efficient transportation of dusts from ESP s, filters or baghouses in a clean, closed pipe system. For Kiln Burner Fuel Injection As Pneumatic Injection technology can inject at higher pressures this enables longer injection distances to be possible compared with traditional injection technologies.

cement preheater design

Preheater Kiln Wear Parts for Cement Plants Columbia Steel. We manufacture wear and heatresistant parts for preheaters and kilns such as thimbles, inlet trays, nose ring segments, tail ring segments, inlet castings. Our engineers work closely with customers to improve parts through design and alloy selection.

3D model Cyclone Preheater Cement Plant | CGTrader

3D model Cyclone Preheater Cement Plant, available in DWG, 3d cement cyclone, ready for 3D animation and other 3D projects

USA Suspension preheater for cement calcining ...

A multistage cement calcining plant suspension preheater has a calcining combustor flow connected with a cyclone separator in the uppermost stage and helical duct inertial separators in the remaining stages which are lower in height and in pressure drop than conventional cyclone separators and permit reduction in height of the preheater tower and use of a lower horsepower fan to move kilnoff ...

"BEST AVAILABLE TECHNIQUES" FOR THE CEMENT .

CEMBUREAU the European Cement Association, based in Brussels, is the representative organisation for the cement industry in Europe. Its Full Members are the national cement industry associations and cement companies of the European Union and the European Economic Area countries plus Poland, Switzerland and Turkey.

Preheater Tower For Cement Manufacturing Process

Evaluation and Structural Retrofitting of a Cement Plant Preheater Tower. Inspection by plant personnel revealed cracking in the concrete frame of a 326fttall, 7level preheater tower. Onsite plant engineers deemed the cracking significant, especially since the structure supports critical manufacturing process equipment. .

Preheater cyclone boosts capacity, cuts energy use

Many plant owners would like to upgrade the preheater in their cement plant – but this can seem out of reach. Excessive civil and structural costs, the impact on plant layout, and installation difficulties all seem to get in the way. Our CCX preheater cyclone can make an upgrade possible, and even attractive from a fiscal point of view.

Cements – Composition, Types Civil Engineering

Not all cement components can be expressed by the oxide formulae and shorthand notation Chlorides, Fluorides etc Expressed using normal chemical formulae Mineral names are commonly used for raw materials (calcite, quartz) and for some cement hydration products (ettringite, portlandite etc)

Low SO2 Emission Preheaters for Cement Production DTU .

Low SO2 Emission Preheaters for Cement Production. ... Citation formats; Documents. Prod. 2 , PDFdocument. By the same authors. SO2 Emission from Modern Cement Plants. Research output: Contribution to ... 2009 › Research › peerreview. The Role of CaO in SO2Abatement in Cement Preheaters. Research output: Contribution to ...

Trends in cement kiln pyroprocessing Cement Lime Gypsum

Specialists from all parts of the globe use this source to obtain vital information on cement, limestone and gypsum materials, extraction and preparation methods, thermal and mechanical processes and on production control, plant management and quality control systems.

Latest Posts

- كسارة فكية الابتدائي للبيع في عمان

- معدات معالجة تعدين الذهب في الولايات المتحدة

- الكسارات الفك مصغرة العراق

- كسارة للبيع أوروبا

- الفك الشركات المصنعة محطم تاميل نادو

- مصنعي كسارة المعادن في الإمارات العربية المتحدة

- آلة كسارة المعادن في سريلانكا

- مصانع الاسمنت العمودية الصينية

- الحديد الصين عملية خام

- كيف يتم سحق خام الحديد

- تخطط لكرة مصنع للكاكاو

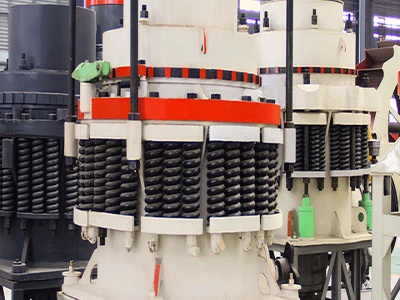

- سعر كسارة مخروطية سلسلة

- مصنعي مطاحن الجبس

- مطحنة الكرة المصنعين مقدمة اليدوي الشعبي

- ريموند تصنيف

- 2nd hand ball mills s a

- heavy equipment road work

- crusher with output of 5 in

- particle size of jaw crusher

- crushed concrete plant

- gold mine near ventersdorp

- blake dodge crusher disadvantage

- maquina para moler carne

- what is bosch grinding machine ag4

- buy ore beneficiation process ore beneficiation

- buy aluminium billet high quality manufacturers

- tracked cone crushers for sale america

- black coal mining industry award 2010

- project for pneumatic embossing machine

- bullnose grinding wheel for cmu