what is ore milling or processing

Metalworking Wikipedia

Metalworking is the process of working with metals to create individual parts, assemblies, or largescale structures. The term covers a wide range of work from large ships and bridges to precise engine parts and delicate jewelry. It therefore includes a correspondingly wide range of .

Mining of Iron Ores – IspatGuru

Mar 14, 2014· Processing of the ore ranges from simple crushing and screening and separating various size fractions of the ore to the processes that beneficiate or upgrade the quality of the iron ore products. This is done by physical processes, which remove impurities by difference in particle density or size gravity or size separation.

Aerial measurements on uranium ore mining, milling and ...

Aerial measurements on uranium ore mining, milling and processing areas in Germany ... due to uranium ore mining, milling and processing, ... The uranium ore milling site of Crossen is located north of the town of Zwickau in the southwestern part of the Federal State of Saxony. Altogether 75 million tons of uranium ore were processed.

Mineral Processing Introduction lve Labs

Mineral processing is a major division in the science of Extractive Metallurgy. Extractive metallurgy has been defined as the science and art of extracting metals from .

processing of gold ore in mill operations

Mill (grinding) Wikipedia. Arrastra, simple mill for grinding and pulverizing (typically) gold or silver ore. Roller mill, an equipment for the grinding or pulverizing of grain and other raw materials using cylinders; Stamp mill, a specialized machine for reducing ore to powder for further processing or for fracturing other materials. Get Price

Free Milling Gold? Findmall

Sep 14, 2011· Free Milling Ores Free milling ores comprise the most profitable gold ores. Quite logically, the ore types that fall under this category promise great gold recoveries, sometimes even up to 99 percent. The best positive with this ore type is that it can be easily crushed, washed and milled to recover the gold contained within it.

How is Tungsten Carbide Formed? | Chronicle

Aug 13, 2015· Approximately 85% of the world's tungsten comes from China and is extracted from various ores. Tungsten ore is refined to form tungsten oxide or pure tungsten powder. The process to combine tungsten metal with carbon to form tungsten carbide () can be accomplished several different ways.

Uranium processing Canadian Nuclear Association

After mining, uranium ore is transported to a nearby mill for processing. The first step is to crush the ore and mix it with water so that it can move through a series of mill circuits. After crushing, the ore is treated with acid in large tanks, to separate the uranium from other minerals in the rock.

Telson Resources Inc. Commences Tahuehueto PreProduction ...

Jul 06, 2017· Press Release Telson Resources Inc. Commences Tahuehueto PreProduction Mining with Ore Milling/Processing at Atocha Toll Mill and Secures USD 1,000,000 concentrate prepayment.

Minetomill optimisation | Metallurgy Mineral ...

Minetomill optimisation: effect of feed size on mill throughput. One of the most valuable aspects of blasting is the generation of very fine particles (, smaller than 12mm) that will pass through the primary mills and onto the secondary ball mill circuits, alleviating a common bottleneck.

The process design of gold leaching and carboninpulp ...

to come by, particularly if the ore is from a deep underground mine. In this case, the most appropriate approach is to use experimental data obtained from a similar pulp on a currently operating plant. Process overview and description The CIP process A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2.

Ore Wikipedia

An ore is a natural occurrence of rock or sediment that contains sufficient minerals with economically important elements, typically metals, that can be economically extracted from the deposit. The ores are extracted at a profit from the earth through mining ; they are then refined (often via smelting ) to extract the valuable element, or elements.

How copper is made material, used, processing, steps ...

Process The process of extracting copper from copper ore varies according to the type of ore and the desired purity of the final product. Each process consists of several steps in which unwanted materials are physically or chemically removed, and the concentration of copper is progressively increased.

Gold Smelting Process | Sciencing

Apr 24, 2017· Ore Processing. The first step in the gold smelting process occurs when ore containing gold is mined from the earth. At this point, the crude binding matter and the gold metal need to be separated. This is accomplished by pulverizing or crushing the .

Introduction to Mineral Processing

Water quality, flotation equipment size and type, temperature, and ore body variation are just a few of the variables affecting the flotation process. Copper/Molybdenum Ore. The figure above is a simplified flow sheet showing the basic steps involved in a copper mill producing the byproduct molybdenum.

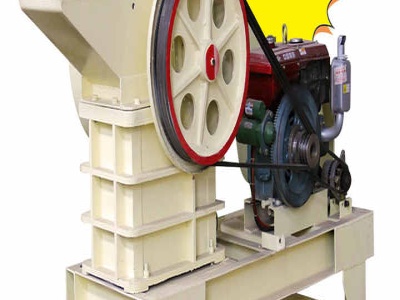

Difference Between Sag Mill vs Ball Mill mech4study

Oct 12, 2017· Today we will learn about difference between sag mill vs ball mill. A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting. This commutation is an essential part of many processes. Various kinds of mills are there with which different material processing takes place.

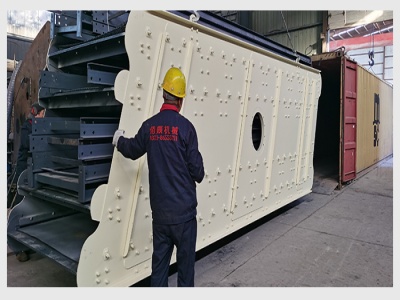

Processing Citic Pacific Mining

Blasted ore from the openpit is delivered to the inpit gyratory crushers by a fleet of 350 tonne haul trucks. The crushed ore is first transported to the coarse ore stockpile by conveyor belts, then fed to each of the six parallel milling lines using apron feeders and conveyor belts.

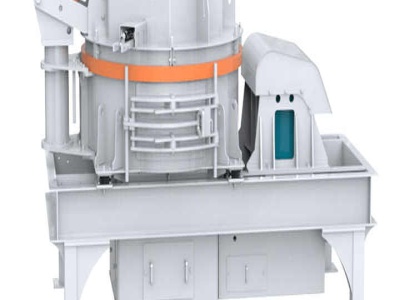

ore processing plant ball mill,spiral classifier ...

Henan Fote Heavy Machinery Co., a professional manufacturer and exporter specilized in the prodution of ball mill, magnetic separator, rubbletyred mobile crushing station, dryer, jaw crusher, Rotary kiln and other large mining machinery equipment.

Mill Gold Ore Processing

Gold Ore Milling and Processing, Mojave Desert Gold. Gold: Gold Mines Desert Mining History Gold and Silver Ore Milling Processing Gold Dry Washer Arrastra Stamp Mill Chilean Mill Silver Smelter Recovery of silver from ore was a different process from that of gold Charcoal Kilns.

what is scrubbing for ore processing BINQ Mining

Sepro has supplied equipment, systems and mineral processing technical . milling, scrubbing, screening, milling and ore, minerals and construction aggregate . » More detailed Drum Washer – Drum Scrubber and Stainless Steel Scrubbers .

Gold toll milling in Peru –

Jun 19, 2015· I tis a good margin / margin protected business – buying ore at a discount to the spot gold price, processing through the plant, and selling the gold or goldincarbon at market.

gold ore milling and processing

the gold ore milling treatment process is the size reduction of the gold ore of gold ore processing machine, like crusher, screening machine, grinding mill for nbsp. Online Talking The jaw crusher, hammer mill and fine gold shaker table form the heart of the basic ore processor system.

Latest Posts

- الجوائز المعدات الدواجن

- قائمة الشاشة بالاهتزاز

- الكرة التطبيقات مطحنة سيتدخل عمل

- سعر آلة صنع مسحوق المنظفات

- استخدامات خام الحديد في الصناعات

- معدات تكسير الخرسانة على الطرق السريعة

- كسارة الفك terowongan

- تستخدم آلة العمود المرفقي طاحونة

- مبيعات كسارة البوكسيت في مصر

- مقارنة الأسعار على آلة طحن الحجر

- تستخدم المطرقة كسارات الصخور للبيع

- مخطط تدفق محطة معالجة الحديد

- كسارة من روسيا

- استراليا سحق النباتات

- محطم وفحص الرسومات مصنع

- mining powered belt conveyors

- gypsum grinding mill manufacturer china gypsum stone grinding

- por le stone mill grainder

- adm mobile crusher

- mobile crsuher for cement mill

- hp 400 cone crusher user manual

- new mining rules for stone aggregates brazil

- ventajas chancadora de cono

- abb vertical coal grinding machine

- machinery for mineralsmachinery for mining diamonds

- prinsip palu crusher pdf

- zenith qj340 crusher manual

- quarry plant and crusher equipment for sale

- ball mill manufacturer at china

- underground mining methods in china