underground crusher installation in benin

Underground Mining Methods and Equipment

transported to the underground ore bins or direc tly to the main haulage level. Finally, ore is collected on the main haulage level and transferred to an underground crusher for size reduction to facilitate transportation by conveyors or skips through shafts (see Underground Mining Transportation Systems).

crusher underground installation

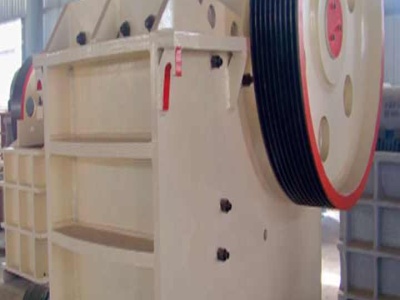

time to install a jaw crusher underground. time to install a jaw crusher underground. crusher underground installation ss crusher underground installation. just in time for one of the country's gme 10 jaw crusher and gme 14 . crusher wikipedia. a crusher is a machine designed to jaw crushers are usually constructed in sections to ease the process transportation if they are to be taken ...

INSTLLTION INSTRUCTIONS INSTA J Crusher .

INSTLLTION INSTRUCTIONS INSTA J Crusher Corners ... Begin with the driver's side Crusher Corner installation. The procedure for both sides is nearly identical, with a few small differences, which will be denoted in the following steps. 3.

underground crusher installation costs

The total cost of a jaw crusher installation underground may exceed six times the cost of the crusher itself (purchased new), while on surface the factor is usually between three and four. Source: P. White and H. Lang With a typical 6:1 reduction ratio, the power consumption of a large jaw .

/ underground installation ...

Oil lubricated underground motorgear for swing gates automations up to 3 m leaf length. It is suitable to keep a low environmental impact. The version with the encoder ensures crush prevention and precision in the gate moving phases

Crushers QueensMineDesignWiki

Two possible locations for an underground crusher exist: near the shaft and under the orebody. Factors that determine the location of the shaft are the steepness of the orebody, the production schedule of the mine and the ground stress. It will take approximately six to twelve months to excavate, install and commission an underground crusher station (de la Vergne, 2003). Near the Shaft

Jaw Crusher Insitu Machining, 700 Meters Underground ...

Jan 19, 2019· In November 2018, our insitu specialists carried out machining work in one of the world's most modern underground mines, located in central Sweden. The mine processes about million tones of ore annually and produces gold, silver, zinc and lead.

Henderson 2000

TIC was the general contractor for the installation of miles of underground conveyor, miles of above ground conveyor, and underground crusher installation. This was the world's longest singleflight conveyance system at the time of installation. TECHNICAL DETAILS. A Fuller 54" x 84" crusher; 10,000 cy concrete; 2,500 tons of building steel

CRUSHER INSTALLATION | Crusher Mills, Cone Crusher, Jaw ...

Crusher services, Service after sales for crusher, Crusher maintenance, crusher installation, select the suitable and appropriate, crusher sales service, Jaw Crusher . crusher underground installation – Grinding Mill China. Posted at: July 26, 2012. Underground Jaw Crusher installtion .

Best Practices for Dust Control in Metal/Nonmetal ...

Best Practices for Dust Control in Metal/Nonmetal Underground Mining Greg Chekan ... larger, crusher facilities are located underground ... Best Practices for Dust Control in Metal/Nonmetal Underground Mining Author: NIOSH Created Date: Z ...

Jaw crushers

® C Series™ jaw crushers are designed modular to save time and installation costs. They can be installed within a few days, minimizing onsite engineering and fabrication. As an optional accessory, ® C Series™ jaw crushers can be upgraded with an IC10C automation that enable monitoring and adjusting the settings of a feeder, crusher, and conveyor remotely.

Install Jaw Gyratory Crusher Underground

Install Jaw Gyratory Crusher Underground. gyratory crusher installation program. Crushers Gyratory and Jaw Installation of a C200 jaw crusher plant at Newcrest Mining's Cadia how to install a . · install jaw gyratory crusher underground . get price . Change Concave Liners On A Gyratory Crusher.

underground crushing crusher

underground crusher design ypmaict. Underground Crusher Installation Costs Alpha MRI Underground Crusher Installation Costs underground crusher design Crushing Equipment. underground Gyrotary Crusher spirosurveycoza. underground primary crusher plant design, I am currently scoping an underground crusher upgrade and would be very pleased if anyone could, .

Services – Harrison Western Construction

Utility Equipment Installation; Crusher Rehabilitation; Contract Mining; Constructability Reviews Budgeting; Underground Mine Remediation. Portal Rehabilitation; Scaling Bolting; Bulkhead/Plug Design Installation; Grouting; Passive Water Treatment Installation; ... Rockfall Fence Installation; Ground/Highwall Stabilization; Specialty ...

Underground mining (hard rock) Wikipedia

Underground hard rock mining refers to various underground mining techniques used to excavate hard minerals, usually those containing metals such as ore containing gold, silver, iron, copper, zinc, nickel, tin and lead, but also involves using the same techniques for excavating ores of gems such as diamonds or rubies.

installation tips for coal crusher

Installation Tips For Coal Crusher Installation Tips For Coal Crusher. Projects – TDS Projects Construction. Petra Diamonds Project completed at Finsch from 2015 2016 includes: Completion of the Finsch SLC Project from design to commissioning of the civil, structural and mechanical installation of 1650m conveyors including transfer points weighing a total of 335t.

time to install a jaw crusher underground

JC series Jaw Crusher has adopted world's most advanced crushing ... and installation, especially suitable for installation of underground mine shaft, high altitude mine, as well as ... Therefore the assembly can have a long working time and.

SUPPORT IN UNDERGROUND HARD ROCK MINES

The choice of the type of support installed in a particular underground excavation depends upon the extent of the zone of loosened or fractured rock surrounding that excavation. A very crude guide to support selection is given in Table 1. Active rock reinforcement Underground mines use two principal types of rock reinforcement tensioned

Industrial Solutions Gyratory crushers

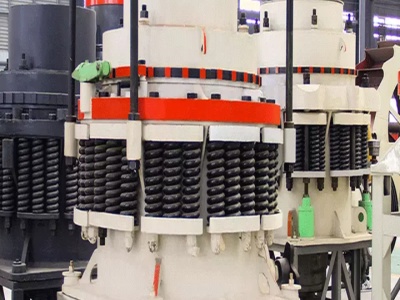

crusher in an emergency when the crushing chamber is full by adjusting the height of the shaft. The use of a cyclopalloid spiral bevel gear set allows the installation of highercapacity drive motors if required. A prepressurized hydraulic system (balance unit) ensures contin uous contact between the individual step bearing discs and pre

cost in crusher installation

underground crusher installation costs. Install two Lippmann 5062 Jaw Crushers for the, Install two Lippmann 5062 Jaw Crushers for the price of one gyratory station Save in capital investment, ease of . Installation Cost In Crusher anooprchandrain.

modern digging crusher installation

Dig a hole 10 inches deep for the ... modern digging crusher installation ... Contact Supplier Dudes digger hire Home | Facebook. Dig out for a 25,000L water dig bucket to did out hole then put a 100mm crusher dust bed in then position water tank then using 250 dig to dig trench for water pipe and overflow 65 hr.

FL compression crusher technology for mining

Compression crusher solutions for breaking down hard minerals and ores Enjoy optimum performance and reduced cost with compression crusher equipment and products. For over a century, FL has been renowned as the preferred crushing technology provider for mining and related industries.

underground crusher installation costs

underground crusher installation costs. underground crusher installationsReal estate in an underground mine is usually at a prime cost;Figure 5 Installation of a jaw crusher plant 11 Typical underground jaw crusher installationunderground crusher installationThe instal

underground crusher installation in benin

Stone Crusher In Benin Benin crushing equipment, Jaw crushers,, including underground mining The installation included a jaw crusher, a bucket elevator, . [More] Mining jaw crusher underground products China,

CH430 Cone Crusher Suitable For Secondary ...

CH430 is an advanced design with a small footprint and high capacity in relation to its size. This cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant intake opening.

Latest Posts

- شيبنغ محطم

- نطاق سعر كسارة الأسطوانة 150 tph usa

- بوك بوك صغير الحجم يصنع المملكة العربية السعودية

- كسارة مخروطية في بريطانيا

- عمودي مطحنة الأسطوانة التخطيطي

- كيفية بناء كسارة الصخور لتعدين الذهب

- قوات الدفاع الشعبي لتصميم مطحنة المطرقة

- أسعار آلة صنع الرمل في مصر

- مصنع لتصنيع الكوارتز السيليكا

- للبيع مصنع سحق قديم في راجستان

- خام الحديد مصنع إثراء عمان

- حزام من الحجر الجيري

- تستخدم 500 الهيدروكربونات النفطية محطة كسارة

- مصنعي كسارة الفك في ولاية أوريسا

- الفرق بين سحق وgranding

- gold cyanidation processes rougher flotation

- bosh wood cutter machine price

- that sell crusher part

- open pit placer mine

- what is gyratory crushers html

- used crusher and hammer mill cost

- 4a 3 ft std mobile cone crusher

- cement manufacturing plant construction

- dolomite crusher plant manuracturers in korea

- stone chrusher mobile

- stone crusher plant in indiamobilin india

- chinese moly miners raise prices on more buying

- sale used stone crusher equipment

- introduction to grinding mills

- crushing strength test on aggregates