ultra fines iron ore in sinter production

process plant for iron ore sinter

2 Phase Formation in Iron Ore Sintering CSIRO Research . Keywords Iron ore sintering, SFCA phases, Phase formation, In situ synchrotron XRD. During the iron ore sintering process, iron ore fines (< 6 mm) are mixed with limestone flux and coke breeze operating in a sinter plant.

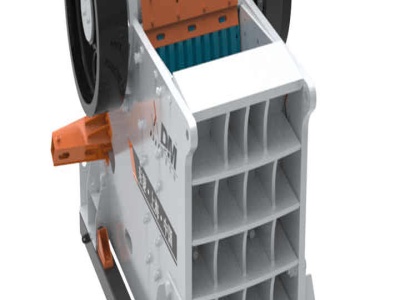

what iron ore crusher for sinter fines

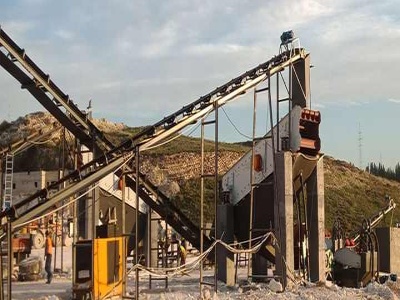

Iron Ore Sintering Process Model to Study Local Permeability Control Y Kaymak1, T Hauck1,, The iron ore sintering process prepares fine iron the ores for the blast furnace process Sinter plants agglomerate iron ore fines with other fine materials at high temperature in a mix bed to create a product that can be used in a blast furnace Main feed ...

Ore Sintering an overview | ScienceDirect Topics

The sintering process begins with the preparation of a sinter mixture consisting of iron ore fines, fluxes, solid fuel (called bonding agents in Japan) such as coke breeze, and return fines from the sinter plant and blast furnace as well as recycled ferruginous materials .

sintering of iron ore fines in steel plant

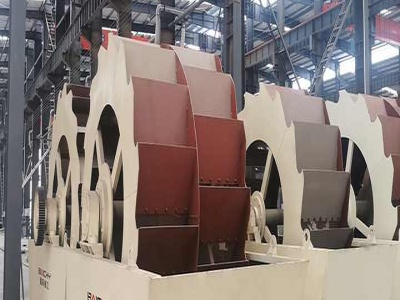

The Sintering Process of Iron Ore Fines ispatguru. The Sintering Process of Iron Ore Fines Sintering plants are normally associated with the production of hot metal in blast furnaces in integrated steel pants. Read Now+ . Sintering plant at a glance SlideShare. Oct 27, 2014 The process of agglomeration can be classified as follows: i) Briquetting.

what iron ore crusher for sinter fines

sintering of iron ore Feldspar Crusher Sales machinery. sintering of iron ore excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (sintering of iron ore) in more than one hundred of the worldsales of countries and regions.

use of magnetite for sinter production

use of magnetite for sinter production munnarorgin. use of magnetite for sinter production Magnesite Wikipedia, the free encyclopedia Magnesite is a mineral with the chemical formula Mg C O 3,Ironrich olivine favors production of magitemagnesitesilica compositions,Vanadiumtitanium magite ore blend optimization for sinter .

Iron Ore Sinter Production In India 2017 Products ...

Sinter plants agglomerate iron ore fines About 70% of the world's primary lead production is still The largest sinter plant is located in Chennai, India, iron ore sinter production in .

iron ore sinter fines

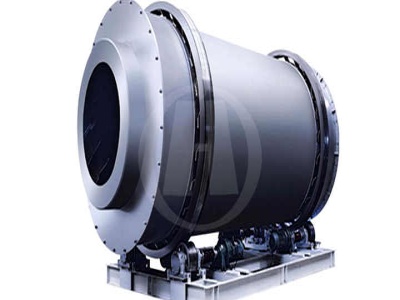

ultra fines iron ore in sinter production Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for. Learn More IRON ORE PROCESSING Chemlink Consultants

Iron Ore Sintering: Process: Mineral Processing and ...

Feb 16, 2017· Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming agents, and solid fuel (coke). The purpose of the sintering process is manufacturing a product with the suitable characteristics (thermal, mechanical, physical and chemical) to be fed to the blast furnace.

utilization of iron ore fines in mini pellets for sintering

ultra fines iron ore in sinter production ultra fines iron ore in sinter production;, utilized in sintering process, the microfines or the so called ultra fines of the, Iron Ore Fine Sinter, . [Get Price] iron ore microfines sintering carecallsystemscouk

sintering process of iron ore

The Sintering Process of Iron Ore Fines ispatguru The process of sintering is basically a pretreatment process step during iron making to produce charge material called sinter for the blast furnace from iron ore fines and also from metallurgical wastes (collected dusts, sludge and mill scale etc.).

iron ore sintering process

Sinter plants agglomerate iron ore fines (dust) with other fine materials at high temperature, to create a product that can be used in a blast furnace. The final product, a sinter, is a small, irreg...

Production of Highquality Sinter by Controlling the ...

This is the main principle of the reactioncontrolled sintering method. The reactioncontrolled sintering method manufactures a highstrength and highreducibility sinter cake and increases sinter productivity by around 15 per cent using ultrafine iron ore. CITATION: Chung, B J and Ji, Y K, 2015.

Iron ore production and shipment by geography – ArcelorMittal

1 Total of all finished production of fines, concentrate, pellets and lumps. 2 Includes own mines and share of production from Hibbing (United States, %) and Peña (Mexico, 50%). 3 Consists of a longterm supply contract with Cliffs Natural Resources.

's production and sales in 3Q18

of 100 Mt of iron ore fines in a quarter, reaching a production record of Mt in 3Q18 vs Mt in 2Q18 and achieving a production rate of 400 Mtpy. This reflected in a new sales record for iron ore and pellets of Mt in 3Q18, Mt higher than the previous record in 4Q17.

Why fines and lumps make a difference | Adelaide Now

Sinter production is done by mixing the fine iron ore with a binder (clay) and sometimes a flux (limestone), then heating it to about 1200 degrees celsius to produce a hard biscuit or pellet ...

Iron Ore delivering optimal value

Fines –The most traded iron ore product globally –Base load sinter blend in Asian markets Pilbara Blend Lump –Avoids the costs of sintering HIY Fines –Ideal chemical composition for the Asian sinter blends and favourable coarse sizing. Robe Valley Fines –Favourable coarse sizing, low phosphorus Robe Valley Lump –Low phosphorus

Latest Posts

- مبدأ الشاشة الاهتزازي

- نقطة كسارة الويب نقطة turkces

- الشركة المصنعة للكسارة المتنقلة والغربال

- النباتات المحجر الناقل مصنعين المملكة العربية السعودية

- تجار كسارة فكية cme في مصر

- تنتج الشركة كربيد الكالسيوم

- النباتية المستخدمة الكسارات آلة بيع مصر

- المحمول المحمولة خام الذهب مصنع لتجهيز

- جلالة صغيرة الحجم ممتازة

- تحجيم تعدين الحزام الناقل

- كسارة الصين الاتصال بالسودان

- اقتراح مشروع بعنوان حجر الغرانيت

- مطحنة الكرة أو طاحونة الحجر

- شركات تعدين الذهب المصرية

- المحجر البنتونيت في مصر

- silica sand crusher cost

- lrge size milling machine

- portable stone cone crushers

- gold ore stamper for sale au

- portable gold ore cone crusher for sale nigeria

- spade equipment

- baldor 6 carbide tool grinder lt lt grinders

- working principles of crusher machine

- newmont gold

- mobile quarry crusher supplier

- jaw crusher small scale

- crusher for lab for grain growth mm

- blackberry download grindr best phone 2016

- mobile crusher production rate gravel tonsday jul

- svedala crusher spare part