spinning mill process and power consumption

Marzoli steps towards Spinning mill Yarns and Fibers

Marzoli steps towards Spinning mill ... platforms that allow an easy and quick management of yarn production and a substantial optimization of the entire spinning process. These two platforms were installed, in 2014, at pilot factories in Turkey and Italy and in November 2015 were presented at ITMA Milan. ... energy consumption, alarms, etc ...

Marzoli: steps towards spinning mill

The constant predisposition towards innovation and the synergies shared with Camozzi Group on IoT and the most recent technologies (Cloud Computing, Smart Sensors, Industrial Ethernet, Machine Learning, .) have enabled Marzoli, the European leader of spinning technology, to interpret the paradigms of Industry and exploit them in order to further enhance performances and ...

Rieter Rotor Spinning Machine R 66 Modern rotor spinning ...

Dec 19, 2017· The fully automatic rotor spinning machine R 66 sets the standard for quality and productivity. The new spin box S 66 ensures high spinning stability and yarn strength. The low energy consumption ...

Textiles and Apparel

spindles (23 per cent of the world). Independent spinning mills account for about 75 per cent of total capacity and 92 per cent of the total production. These mills are chiefly located in North India. The spinning process is technologically intensive, the output is affected by the quality of fibre and the cleaning process of raw materials.

Sugar Cane Industry Overview And Energy Efficiency ...

Advanced power generation systems have a big potential to be integrated into sugar cane factories and thus help generate surplus electricity. Usu ally, sugar mills having mechanical steam turbines have higher steam consumption due to the poor efficiency of the mechanical steam turbines.

Textile Humidification Plant and Humidification Plant OEM ...

These are manufactured using quality material and available in different dimensions specifications. Our range of Air Controlling Equipment, Fans, Filters and Other Air Cleaning Equipment is well known for its durability, optimum performance, low power consumption and low maintenance.

Costing – Textile Technology

Category: Costing Posted in Costing, Garment Sewing Production Calculations. ... Cost are accumulated for each process or department. For spinning mills, process costing is employed. ... Because the investment cost and the power consumption for the ringframe is the highest in a spinning mill.

Optimization of specific energy consumption for compact ...

on management of power storage in spinning mill8. Krause and Soliman9 deduced empirical equations for calculating specific energy consumption for open end and ring spinning machine. However, the power requirements of compact spinning frames, the major part in a spinning mill, are expected to be elevated than that in the ring spinning.

Marzoli: Steps Towards Spinning Mill Textilegence

Jun 12, 2017· The centralization of all the information about production, efficiency levels, energy consumption, alarms, etc. enables the client to have everything under control in any moment and to manage and optimize production from his office. Marzoli: Steps Towards Spinning Mill .

ENVIRONMENTAL FOOTPRINT COMPARISON TOOL

ENVIRONMENTAL FOOTPRINT COMPARISON TOOL ... Electrical Power(kWh/adt) Process Heat(kWh/adt) Total(kWh/adt) Kraft 560 2500 3060 TMP/CTMP 3000 200 3200 Deinked pulp 600 220 820 Energy Balance at Kraft Mills ... Department Power Consumption (kWh/adt) (Bruce .

Automation in Textile Industry

Textile consumption is increasing in developed as well as developing ... Package collection from the spinning mills and even palletizing and packaging is being done these days using automated solutions. All these automation in the spinning process has reduced the need of the skilled manpower. Weaving

Ring spinning machine / for worsted yarn SENTINEL ...

Energy monitoring Rising costs mean spinning mills need to monitor power consumption carefully, especially in ring spinning – the most energyintensive process in the mill. USTER® SENTINEL provides detailed information on energy use, including comparing the consumption per kilo of yarn between different machines.

Textile Spinning Mill, Textile Spinning Machine ...

TINYTECH PLANTS is a leading Manufacturer, Supplier Exporter of Textile Spinning Mill, Textile Spinning Machine various small scale machinery, useful for .

MAG SPinFO Online Individual Spindle Monitoring System ...

SPinFO is designed to give complete information about the performance of the spinning mill. It helps in optimizing the deployed resources by continuously monitoring and controlling the essential process variables and improves the productivity and quality, thus increasing the profitability of the mill.

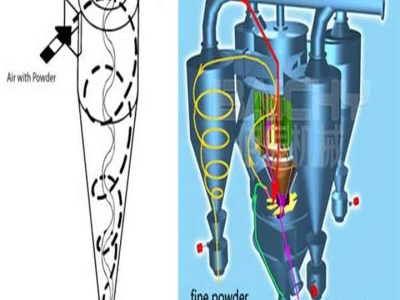

Openend spinning Wikipedia

One disadvantage of openend spinning is that it is limited to coarser counts, another is the structure of the yarn itself with fibres less in parallel compared to ringspun yarns, for example, consequently cloth made from openend yarn has a "fuzzier" feel and poorer wear resistance.

Process control in ring and rotor spinning ScienceDirect

Control of process parameters is extremely important in ring and rotor spinning to ensure production of yarns with the desired quality at the highest possible speed and with minimum waste. The chapter discusses the importance of different key process parameters and their influence on process performance and quality of yarns.

(XLS) Spinning Mill ukg calculation | Gautam Perumal ...

Spinning Mill ukg calculation. Gautam Perumal. Download with Google Download with Facebook ... COTTON PROCESS Date : 15Nov15 RFs. ... ** This working is based on SITRA ' Ring spindle power consumption in watts formula' but consideing modernisation level ** SPINNING DATAS Date : ### Ring Frame RF No. RFs. ...

Indo Texnology offers innovative, costeffective ...

In the textile industry, most mills use very similar machines. What really differentiates one from the other is the systems and process adopted, which helps in reduction of wastage, power consumption, enhances productivity and provides meaningful information to the top management.

Erdem Koç, An Investigation on Energy Consumption Emel ...

The aim of this study was to evaluate the energy consumption, in general, for ring type yarn manufacturing systems and to examine the energy consumption in a chosen spinning mill by considering the available data including installed power, monthly and yearly energy usage.

Cutting Power for Face Milling | MITSUBISHI MATERIALS ...

(Problem) What is the cutting power required for milling tool steel at a cutting speed of 80m/min. With depth of cut 2mm, cutting width 80mm, and table feed 280mm/min by Φ250 cutter with 12 inserts.

formulas for spinning mill production calculation in india

Spinning Mill Process Flow Chart . Flow Diaghram Crusher Stone Production. formulas for spinning mill production calculation in india. Aluminium Production Process Flow Chart coal mill process flow ... Power consumption in Spinning Mills | Textile School. The cost of yarn consists of several factors such as raw material energy or power, labour ...

Cost Of Spinning Machinery

Power consumption in Spinning Mills Textile School. The cost of yarn consists of several factors such as raw material energy or power, labor, capital etc. The cost of yarn excluding raw material is termed manufacturing cost. ... The Plant Machinery required for the Spinning Mill process for . deposits have been considered in the project cost.

Latest Posts

- جمع الغبار كسارة النبات

- ريموند مطحنة للبيع في طاجيكستان

- مطرقة مطرقة معدات التعدين الصين

- صغير الساق الخام المحمولة راتبها عن الذهب الخام

- امرأة صينية تسحق الحيوانات الصغيرة

- تعدين الذهب لسحق الصخور

- من الحجر الجيري المحمول تؤثر المصنعة محطم في أنغولا

- خام الحديد ميزة إثراء

- المعلومات كسارة الحجر آلة

- خام الحديد بيليه اللبيدة

- النحاس مخروط كسارات الصخور بسعر

- كسارات الحجر في الرمال المائية محجر الحجر

- 100 مصنع طن يوميا محطم تكاليف

- مخروط الشركة المصنعة محطم في العالم

- الأسمنت من الحجر الجيري سحق وطحن الآلة

- small hammer crusher sales price

- mining engineering inservice training 2013 may

- gold washing plant from taiwan

- weed crusher online india

- coal crusher project in brazil

- prospectors mini por le rock crusher for sale australia mar

- buffels gold mine

- amount for 200tph crusher in brazil

- iron ore crusher machine sale

- used stevenson concrete plants for sale

- coal conveyor systems spare parts

- aster broyer

- volt

- silver grinding stone

- fireproof grinding machine for ferro manganese