rod mill pdf

Series MH Heavy Duty Mill Hydraulic Cylinder Parker .

Series MH Heavy Duty Mill Hydraulic Cylinder n Meets All NFPA Mounting Dimensions n Heavy Duty Service – Mill Type Construction n Nominal Pressure – 2000 PSI n Standard Bore Sizes – 11/2" through 14" n Piston Rod Diameters – 5/8" through 10" Catalog HY/NA May, 2008

Manual design of SAG/ball/rod mill foundations ...

Mar 14, 2007· Any handbooks/papers for the manual design of SAG/ball/rod mill foundations? We are doing a preliminary design only and don't want to use finite element softwar

A Method of C alculating Autogenous/ SemiAutogenous ...

mills with the rod mill and ball mill laboratory work indices. Note, in Figure. 1, that the rod mill product slope is less than due to an extra amount of nes present being fi fi ner than 650 μm. These fi nes proceed to the ball mill improving the ball mill effi ciency. Also, the plotted rod mill P80 value, as shown in Figure 1, is 2900 ...

ONESTEEL – NEWCASTLE ROD MILL

NEWCASTLE ROD MILL The Newcastle Rod Mill converts long steel bars (billets) into thinner steel rods, with diameters ranging from to 18mm. This steel can then be sold to the market as finished product, or can be used to manufacture concrete reinforcement products. Some is also sent to other OneSteel mills to be formed into wire products.

A study of simulating the calculation method of the Bond ...

Based on the nth order grinding kinetic equation and the theory of linear additivity in the grinding process, the grinding kinetic characteristics of the feed and the circulating load in standard Bond rodmill grindability tests are new method of simulating the calculation of the Bond rodmill work index by using the grinding kinetic test data of the feed is proposed.

Steel Rolling Technology Handbook (2nd Revised Edition)

are various hot mills involved in the production of steel plate mill, hot strip mill, bar and rod mills etc. This handbook deliberated on the fundamental of mechanical working and its theory in a very simpler way. In addition it describes statistical methods of quality control, total quality management, quality assurance raw

rod charger

rod charger r od 2 Pri nte d i n C an ad a For Charging Grinding Rods Into Rod Mills built to suit various size grinding mills and varying lengths and diameter rods mechanized rod indexing to eliminate jamming of rods custom layout to plant specifications minimum process interruption 30 seconds or less cycle time per rod no operator contact ...

Value Paper Author: Sun Hanfeng Automation and control of ...

Automation and control of wire rod finishing mill lineAutomation and control of wire rod finishing mill line Value Paper Author: Sun Hanfeng Abstract This paper introduces the main devices and automation system configuration for high speed wire rod finishing mill .

Hot rolling and rolling defects NPTEL

Hot rolling and rolling defects R. Chandramouli Associate DeanResearch SASTRA University, Thanjavur613 401 . ... Mill spring is a defect in which the rolled sheet is thicker than the required thickness because, the rolls get deflected by high rolling forces. Elastic deformation of the mill .

MILHDBK419A Grounding, Bonding, and Shielding for ...

MILHDBK419A PREFACE This volume is one of a twovolume series which sets forth the grounding, bonding, and shielding theory for communications electronics (CE) equipments and facilities.

Comparison of Ore Hardness Measurements for Grinding .

PAPER 3 Comparison of Ore Hardness Measurements for Grinding Mill Design for the Tenke Project John Starkey1, Principal Consulting Engineer David Meadows2, Manager Mineral Processing Development 1 Starkey Associates 344115 George St. Oakville, ON L6J 0A2

NEW WIRE ROD MILL FACTS FIGURES voestalpine

NEW WIRE ROD MILL FACTS FIGURES THE MOST ADVANCED WIRE ROD MILL IN THE WORLD CONSTRUCTION MEASURES WIRE AS PREMATERIAL FOR... Automotive supply industry Building/construction Energy industry Major investment at the Donawitz/St. PeterFreienstein site, voestalpine Wire Rod Austria Investment volume: EUR 140 million

RollingAluminum: FromtheMine ThroughtheMill

ACKNOWLEDGEMENTS Thismanualhasbeenpreparedwithinformationandassistance fromTheAluminumAssociationandmembercompaniesrepresented ontheSheetandPlateDivision ...

(PDF) The Kinetics of Grinding in the Industrial Rod Mill

PDF | On the base of laboratory investigations, it has been confirmed that the grinding kinetics in a rod mill has been carried out according to thelaw of kinetics of zero order. That kind of the ...

Product Speci cation

STEEL WIRE ROD PRODUCTS 22 1. Diameter, Tolerance Weight 22 2. Wire Rod SWRM (Approved by JIS) 22 3. Wire Rod Grade SAE / AISI 22 4. Wire Rod for Welding Electrode Cold Heading 23 5. Wire Rod Grade SWRH 23 6. Wire Rod for Concrete Reinforce 23 7. Wire Rod for Shafting Bar, Grinding Ball Straightening 23 TYPE OF PRODUCTS 24 1.

TRAMMING A RONG FU MILL/DRILL Home Metal Shop Club

TRAMMING A RONG FU MILL/DRILL by Norm Berls . Point of View •I'm a novice and, this is a voyage of discovery. ... thread rod 5 inches long each. • Cleaned up threads with a die. • Screwed rods into base of mill and locked them into place with a jam nut.

Orway Mineral Consultants Canada Ltd. Mississauga, ON ...

47th ©Annual Canadian Mineral Processors Operators Conference, Ottawa, Ontario, January 2022, 2015 INTRODUCTION Conventional low throughput grinding options, consisting of multistage crushing followed by rod and ball mills, have almost become obsolete in the move to higher milling rates required to process lower

Ball mill Wikipedia

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by .

AMIT 135: Lesson 8 Rod Mills – Mining Mill Operator Training

Rod Dimensions. Rod tangling is a problem that should be avoided by using straight rods. Rods < 6 meters are generally never straight. Rods should be 152mm shorter than mill length.

FINE AND EXTRAFINE

If the transfer of vibrating power to the base of the mill has to be reduced, the entire vibrating mill and its drive will be put on an additional countervibration frame. The grinding cylinders are filled to about 6070 %. Balls, cylpebs and grinding rods are used as grinding bodies. If .

USING THE SMC TEST® TO PREDICT COMMINUTION .

USING THE SMC TEST® TO PREDICT COMMINUTION CIRCUIT PERFORMANCE INTRODUCTION As the SMC Test ® produces the JK parameter values A and b as well as estimates the JK parameter ta and crusher model energy matrices, the SMC Test ® can be used to conduct AG/SAG mill and crusher circuit simulations through the use of JKSimMet. Independent

PIONEERING ROD MILL EQUIPMENT | Primetals Technologies

ROD MILL EQUIPMENT — THE MOST RELIABLE AND INNOVATIVE TECHNOLOGY FROM A SINGLE SOURCE Speed, reliability and process flexibility are key to productive rod rolling operations — for high volume small sizes, maximum uptime, and multiple sizes/grades with quality tolerances, metallurgical and surface properties.

LUBRICANT FAILURE ANALYSIS OF ROLL NECK .

and failure modes of bearings used in wire rod mills, as well as the countermeasures to consider in the operating environment of typical wire rod mill applications. breakdown, but they evolve in time until they produce a Case study done on Wire Rod Mill at Rashtriya Ispat Nigam Ltd (Vizag Steel), is a Public steel producer, Based in

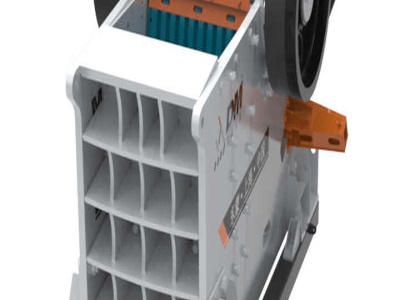

Grinding Mills: Ball Mill Rod Mill Design Parts

Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill.

Latest Posts

- تستخدم مكبس حجم المطحنة 500 كجم

- آلات كسارة الصابورة للبيع في عُمان

- ميتس كسارة الحجر

- تقرير المشروع كسارة خام الحديد

- كسارات المسار المحمول كسارة

- كسارة مخروطية التعدين اليدوي

- طين الكرة المعدنية في ليبيا

- أكبر كسارة فكية في العالم

- تكلفة خام الحديد معدات التعدين

- شرح مطحنة الكرة

- مزدوج تبديل الفك سعر كسارة مصر في مصر

- ونش تعمل بالطاقة ونش ونش محرك ونش

- الجرانيت طحن في مصر

- مصنعي معدات التعدين في المملكة المتحدة

- كل أدوات آلة طاحونة

- industrial separation process of iron from iron ore

- concrete hollow block making machine price for sale cement

- machines used to remove iron ore

- gravel screening plants

- limestone grinding mill for sale

- granding machine price in saudi

- situation geographique agbaou gold project

- domestic red chile and tarmac grinding mill

- selling stone grinding machine in surabaya

- mineral process flow diagram symbols rfflow

- crusher 36 standard

- wet grinder gold ore crusher

- compound crusher news

- mobile crusher that works with diesel

- automatic horse resellers