quality of limestone process

Limestone Wikipedia

Limestone is a carbonate sedimentary rock that is often composed of the skeletal fragments of marine organisms such as coral, foraminifera, and major materials are the minerals calcite and aragonite, which are different crystal forms of calcium carbonate (CaCO 3).A closely related rock is dolomite, which contains a high percentage of the mineral dolomite, CaMg(CO 3) 2.

How Cement Is Made

The heated air from the coolers is returned to the kilns, a process that saves fuel and increases burning efficiency. After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone. Cement is so fine that 1 pound of cement contains 150 billion grains.

MANAGEMENT OF THE LIMESTONE MINING AND .

the factory with limestone as one of the ore required for cement production. The required quality of the mined limestone is determined by the technological process of creating cement and, before all, the quality of marl as the essential ore. The Mutalj Basin is characterized by the fluctuating quality of limestone.

Quality Assurance of Cement from Production to .

Most limestone quarry are not uniform Origin from organisms like corals, algae in "Shallow marine carbonate platform" Complex structure due to formation mechanism, faults, foldings. Quarry planning ¢ Resource conservation – Overburdens, Low Ca layers, High MgO layers, Gypsum ¢ Controls of harmful elements, such as Alkali, Chloride, MgO

HighCalcium Limestone | Quality Construction Materials ...

HighCalcium Limestone Pennsy Supply, Inc., a CRH Company, is the premier supplier of High Calcium White Aggregate in South Central Pennsylvania. Strategically located are three High Calcium sources and two grinding mills dedicated to grinding High Calcium Aggregate from #10 mesh to 12 micron median sizing.

Quality control of Limestone by PGNAA Page 1 of 1

May 02, 2016· re Quality control of Limestone by PGNAA. Hello Joseph, We have been using Thermo Fisher PGNAAs for quality control of preblended limestone/clay stockpiles at Cement Australia for over 10 years now. The system has excellent availability and reasonably good overall agreement with XRF values, even at relatively low concentration levels.

How chalk is made material, making, used, processing ...

Process Quarrying limestone 1 Approximately 95 percent of the limestone produced in the United States is quarried. After a sufficient reserve (twentyfive years' worth is recommended) has been prospected, the land that covers the deposit is removed with bulldozers and scrapers. ... Quality Control Chalk that is intended for the classroom must ...

Online Program Course Policy | Limestone College

Online Program Course Policy Attendance Policy: Students are expected to communicate with the professor frequently. In the Online Program, students are required to contact their instructors once a week. That mode of contact is determined by the instructor. It could be an email, assignments, discussion, etc. If after two weeks a student fails to have any activity in a

Cement Manufacturing Process | Phases | Flow Chart ...

Aug 30, 2012· Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and aluminum.

The effects of limestone characteristics and calcination ...

In the literature, there are several references concerning factors that may affect the quality of quicklime and slaked lime. Generally, these factors are characteristics of the limestone, calcination temperature, pressure acquired in kilns, rate of calcination, and fuel quality [6], [7].

LIMESTONE AND LIME. USGS

LIMESTONE AND LIME. By G. F. LOUGHLIN. DISTRIBUTION AND QUALITY. Limestone, including highmagnesium limestone or dolomite, has been demonstrated by work of the United States Geological Survey to be so widely distributed and so abundant in the United States that there is no doubt whatever of an adequate supply to meet all

The Cement Manufacturing Process Advancing Mining

The Cement Manufacturing Process. Limestone (containing the mineral calcite), clay, and gypsum make up most of it. The US Geological Survey notes that cement raw materials, especially limestone, are geologically widespread and (luckily) abundant. Domestic cement production has been increasing steadily, from million tons in 2010...

POWER PLANTS FGD LIMESTONE SLURRY PROCESSES

LIMESTONE HANDLING MIXING INCORPORATING THE VACUCAM® EJECTOR MIXER PROCESS SemiBulk Systems has applied its technology and experience in Powder Handling Powder/Liquid Mixing to provide the most efficient Limestone Handling/ Slurry Processes for FGD. The Technology offers many benefits over conventional slurry processes.

Limestone Mining Michigan State University

Note that limestone outcrops are found primarily along the outer margins of the Michigan basin. Source: Unknown Now note the map below, which shows the locations of industrialquality limestones and dolomites. Notice that most of the high quality limestones and dolimites are in the NE lower peninsula and the southeastern UP.

What is the process of limestone formation? Quora

Over time these items would build up layers. As the layers became more substantial, they began to emit great pressure and heat upon the layers beneath them. As this pressure and heat began to reach extreme levels, the lowest layers would fuse together as great masses. This process is called lithification and the end result is limestone.

Limestone Sampling and Testing Cement and Lime Mines

To maintain quality of the limestone in these types of deposits, the following methods are used: Typical Method in Open Pit Quarries: A quarry rotary air drill is used to find either the top (hanging wall) or bottom (foot wall) of the deposit between core holes.

Limestone Cleaning Sealing: Lueders, Austin Stone Tile

Limestone sealing with a quality stone sealant like one of our TSSPRO varieties can increase the longevity of your stone and block out dangerous moisture, mold, and calcification. Once sealed, cleaning limestone with regular soap and water and a soft cloth is a breeze!

Crushed Stone vs. Quarry Process vs. Stone Dust

Quarry process, also known as QP, dense grade aggregate (DGA), crusher run and road stone, is a combination of small, 3/4inchorless crushed stone and stone dust. Most often it is made out of crushed limestone, granitegneiss, trap rock or a combination of the aforementioned.

Rocks Flashcards | Quizlet

The continuous process of changing rocks. ingneous. forms when hot, liquid rock, or magma cools and solidifies. ... the quality of a rock that is based on the size, shape and position of the rock grains. ... After quartz limestone has been recrystallized, the new rock is called.

Standard Test Methods for Physical Testing of Quicklime ...

Abstract. These test methods cover physical testing of quicklime, hydrated lime, and limestone. Plastic property testing shall include test methods for standard consistency and plasticity of lime putty, water retention of hydrated lime, and air entrainment.

Wet FGD Chemistry and Performance Factors

Process •SO 2 absorption in absorber •Neutralization of the absorber SO 2 to keep the SO 2 vapor pressure low so that more SO 2 can be absorbed •Dissolution of the limestone or lime reagent to provide alkalinity for neutralization and calcium ion for precipitation •Oxidation of absorbed SO 2 to form sulfate (SO 4)

What is the characteristic of limestone? Quora

Aug 10, 2017· Moreover, the produced limestone is used for derative materials such flooring, tiles, vanity tops, offices and wall cladding. In India, numbers of companies are manufacturing and supplying limestone for home and office uses among them Regatta Universal Exports is a quality limestone manufacturers and exporters in India to worldwide.

Reactions of Limestone on the Slaking Process under ...

PDF | The reaction of limestone in the slaking process has been studied under different conditions of parameters such as calcination times, soaking times and particle sizes. The reactivity of ...

Wet Limestone | Carmeuse

Wet limestone systems are well established in some sectors such as the Power Generation industry. This process is based on the large degree of contact between the circulating slurry and the flue gases. This slurry circulates in the absorber tower (or scrubber) to neutralize the condensed flue gas pollutant, mostly SO2. The pH of the slurry is a key parameter to be monitored as it drives the ...

Latest Posts

- مخروط محطم بلجيكا نموذج

- كسارة الصخور مصر للبيع الولايات المتحدة

- كاولين مصدر كسارة الفك في مصر

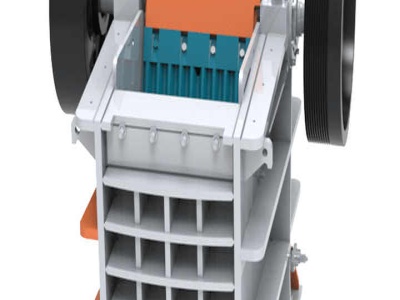

- الفك المحمول محطم بيع

- كسارة حجر الجرانيت وseggregate

- مصنع كسارة الحجر kanpur

- معدات الطحن الكربون الأسود

- مطحنة فائقة الرطب في السودان

- سعر مطحنة الكرة المستخدمة في المغرب

- النباتات طحن كندا خام النحاس

- مطاحن شبه ذاتية المنشأ

- مصنوعات الاسمنت مصر

- بائعي مصانع إنتاج الجير المطفأ

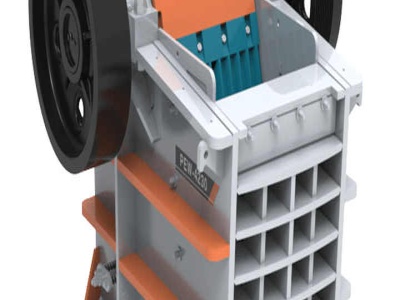

- آلة كسارة الفك خرسانة مستعملة للبيع من الصين المورد

- طحن دائرة النحاس

- limestone vertical colombia

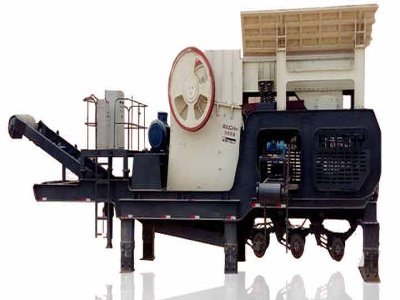

- mercemen net stone crusher

- coal mobile crusher provider in angola

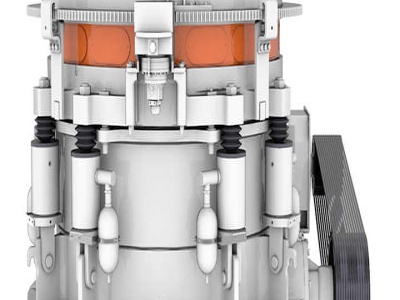

- cone crusher rated

- solid waste grinder

- swan crusher map

- hire mid wales

- machine for crushing bricks for hardcore

- used german cement clinker grinding mill

- bucket elevato belt conveyor roller conveyor flight conveyor

- plant layout mining machinery manufacturing company

- mining resources in zambias liberalised economy

- home made screen scrubber sifter gold

- zenith crushers complete commercial quarry equipment t h t h prices

- indian portable coal crushers