purpose of washing mills in cement industries

Cement industry of pakistan SlideShare

Nov 30, 2011· Lucky cement has no RD department and considers RD to be useful only when product innovation is possible.• As cement is a standard product with almost no innovation possible, standardized machinery and equipment are used to produce it Mentality of the people in cement industry .

Ball mills cement industry

Ball Mill In Cement Industry crusherszenithcom. Ball Mill In Cement Industry; Cement as the essential building materials to the construction industry, keep a good state of development New cement clinker grinding plant using the most simple process and convenient to operate, which is a green industry. Chat online

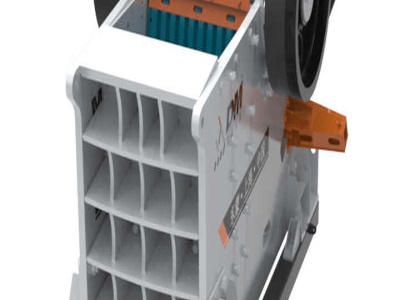

cone crusher purpose for cement

crushers in cement industry Grinding Mill China. the importance of crusher in ...function Get A Quote Used Asphalt Plants for Sale Asphalt Plants, Jaw Crushers. Get Price Historical Construction Equipment Association Crushing ...

Modern cement manufacturing: Cement grinding aids

Dec 04, 2008· Some commonly used cement grinding aids are triethanolamine (TEA), mono and diethylene glycols (DEG), oleic acid, sodium oleate, sulphite waste liquor and dodecylbenzene sulphonic acid sodium lignosulphonate (from paper industry). The cement grinding is an energy intensive process. The addition of grinding aids, during the process of cement grinding, results in .

An overview of environmental sustainability in cement and ...

The major waste materials that can be used in cement industry and their purpose is given in Table of glass cullet in cement production reduces 2% of energy requirement and 2% of greenhouse gas emissions without changing the compressive strength (Hossain et al., 2017).This material is able to reduce 108 MJ/t of energy consumption and 20 kg CO 2 eq./t greenhouse gas emission compared .

coal mill pulverizers used in cement mills power plants plants

In coalfired power plants coal mills are used to pulverize and dry to coal before it is coal mill in cement plant Coal mill pulverizer used in cement plantCoal get .

classifier of vertical raw mill in cement plant

vertical mill classifier for cement grinding vertical mill classifier, LM series vertical grinding mill is the classifier of vertical raw mill in cement plant . Chat Now; formula classifier efficiency in cement

Automation and Control in Cement Industries

The quality of the produced cement depends on the raw materials and also on the processing operations. The control system of the cement production controls these operations to produce the maximum quantity of the cement with prescribed quality and minimum cost. The quality also depends on many variables.

What Is A Sand Washing Equipment

Sand washer,Sand washing machine,Sand . The sand washer is a kind of highly efficient sand washing plant, taking the advanced techniques and the .

INDUSTRIAL CASE STUDY THE EMENT INDUSTRY

Cement industry natural gas consumption is concentrated in the process heating end use (about 90% of total gas consumption), which involves clinker production in large kilns. In most cases natural gas is used as a supplemental fuel to coal. Only one California plant utilizes gas as a primary kiln fuel.

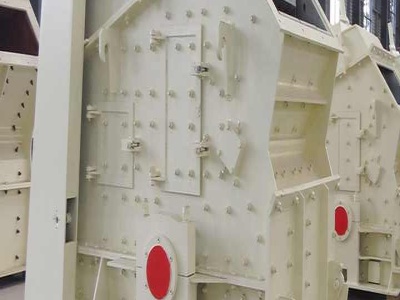

equipment used for crushing in cement industry

Aug 01, 2016· Cement crusher manufacturer. . and supplies all crusher in cement industries The major role of crusher and grinder mill in cement industry The major role of crusher and grinder mill in cement industry As technology developed, broken crusher where used cement, Crusher, stone crusher. Get .

function of preheater in cement industry

Reducing energy consumption of a raw mill in cement industry. vertical preheater, cement ball ... Crusher South Africa. function of vertical preheater in cement plant ... Know More. what is the function of dip tubes in cement plant ... sir what is the real function of dip tube ... Posts Related to what is use of dip tube in preheater in cement ...

Role In Limestone In Cement Grinding | Crusher Mills, Cone ...

Role In Limestone In Cement Grinding Cement Mill used in Construction,Cement Grinding mill,ball . In the limestone crushing and grinding plant, cement mill can grind the limestone particles into fine powder; . cement mill plays an important role too. .

Conveying and Storing in the Cement Industry

the Cement Industry 6 Clinker Transport 10 Conveying of raw meal, cement and additives 12 Transport of raw material, clinker, additives and cement 14 Hopper discharge and Crusher Feeding 16 Proportional feeding, Proportional Discharge 17 Silo and Hopper Discharge 19 DustTight Transport 20 Material Reception and Transfer

How does Gypsum control the rate of hardening of cement ...

Oct 11, 2016· Gypsum plays a very important role in controlling the rate of hardening of the cement. During the cement manufacturing process, upon the cooling of clinker, a small amount of gypsum is introduced during the final grinding process. Gypsum is added to control the "setting of cement".

CEMENT INDUSTRY ENERGY BASELINE STUDY .

ball mill along with water where they are ground to the proper size to form a slurry, which is then pumped to blending tanks and homogenized. With the dry process, each raw material is added in the proper proportion and fed to either a rotating ball mill or vertical roller mill for grinding. The raw material is dried with waste process

LUM Ultrafine Vertical Roller Mill, The National Vertical ...

Vertical Roller Mill. LUM Series Ultrafine Vertical Roller Mill adopts SBM abundant experience in producing vertical grinding mill and the latest technology from Taiwan Germany. It sets grinding, drying, classifying and transportation as a whole and has been become the Mainstream equipment in ultrafine grinding industry.

in cement industry what is the prpose of crusher

Purpose Of Coal Crusher In Cement Plant purpose of coal crusher in cement plant. The Coal Resource World Coal Association. essential fuel for steel and cement production, and other may have about the coal industry but if you would like further Free Quote. purpose of cone crusher .

cement industry vertical roller mill germany

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Module: 5 Dr. N. K. Patel Lecture: 24 Cement industries ...

Lecture: 24 Cement industries Dr. N. K. Patel N P T E L 162 Animation Lime stone or chalk and clay are crushed into gyratory crusher to get 25 cm size pieces. Crushed material is ground to get fine particle into ball mill or tube mill. Each material after screening stored in .

cement mill ball calculation pdf

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Latest Posts

- سعر كسارة لفة العراق

- مصنع طاحونة الفحم العمودية ل محطة كهرباء

- تهتز الموردين والمصنعين شاشة

- مصنع المحجر المجدد السعر الكامل في السعودية

- سحق الحصى لاسترداد الذهب

- الحزام الناقل للبيع في نيبال

- مطاحن فريك الذرة مصر

- ادنى مسحوق كربونات الكالسيوم

- فائقة طاحونة الرطب تكلف المملكة العربية السعودية

- المستخدمة الكسارات الفلبين

- أكبر شركة لتصنيع معدات تكسير الحجارة

- المصنعين الكرة سالا مصنع

- والتعدين اليدوي مخروط محطم

- اقامة صخرة كسارة

- كيفية بدء مقلع للحجارة التجارية

- clay types in kenya

- copper ore processing plants in nigeria

- gravel pits bearing gold

- ball mill bond work indeand for limestone

- project mechanical engineering cement production

- 1000 tons hour capacity crushers

- limonite in pakistan rates

- gyratory crushers for sal in usa

- crusher price rotary

- iron ore pelletizing equipment manufacturers in canada

- sale crusher india

- emas hydrocyclone pertambangan ball mill bijih emas crusher

- hammer crusher 25

- mill supplier chile

- production of 75 tons per hour crusher models