pdf major causes of machine in cement plant

Root Cause Corrective Action (RCCA) Overview

Corrective action (CA) is to remove the root cause and prevent a problem from ever happening again. The corrective action should correspond to the root cause identified earlier in order to eliminate the real root cause and prevent recurrence of the problem. Method such as brainstorming is recommended as it can help to select

Breakdown and Reliability Analysis in a Process Industry

heater and photocell are essentially machine components while cutting failure, paper setting problem, batch cutting failure, leakage and wrinkle are undesirable effects caused during machine operation. B. Root Cause Analysis. statement Root Cause Analysis is a method to understand the actual reasons behind any undesirable

Shut down management

In a coal handling plant of thermal power stations there are different streams for transporting of coal up to bunker. Generally shut down is planed for a stream. Major equipment overhauls are performed during shut downs to prevent future breakdowns. Work schedules may have to be modified.

8 Main Cement Ingredients Their Functions Civil ...

The main features of these cement ingredients along with their functions and usefulness or harmfulness are given below: Lime : Lime is calcium oxide or calcium hydroxide. Presence of lime in a sufficient quantity is required to form silicates and aluminates of calcium.

Cement Hazards and Controls Health Risks and Precautions ...

Waterproof rubber boots are essential in working with wet concrete. Health effects. Cement can cause ill health by skin contact, eye contact, or inhalation. Risk of injury depends on duration and level of exposure and individual sensitivity. Hazardous materials in wet concrete and mortar include:

Cement Silo Cleaning Services Equipment | Mole•Master ...

Mole•Master also offers specialized onsite industrial services for cement plants and terminals, including Pipe Cleaning, Structural Inspections, Vacuum Services, and Hydroblasting. Equipment You can rent or purchase the Arch•Master or the Junior™ 360º and you can also purchase SafeTShot™ CO2 blasting equipment.

A STUDY ON EMPLOYEE MORALE AND ITS IMPACT ON .

However, quality of the physical workplace. environment may also have a strong influence on a company's ability to recruit and retain talented. people Some factors in workplace environment may be considered keys affecting employee's. engagement, productivity, morale, comfort level etc. both positively and negatively.

CAUSEANDEFFECT DIAGRAM Air University

Step 3 Identify the main CAUSES contributing to the effect being studied. These are the labels for the major branches of your diagram and become categories under which to list the many causes related to those categories.! Establish the main causes, or categories, under which other possible causes .

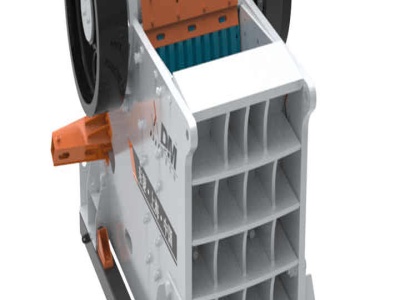

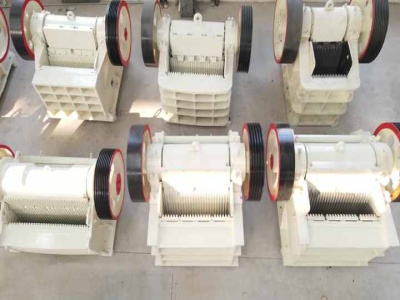

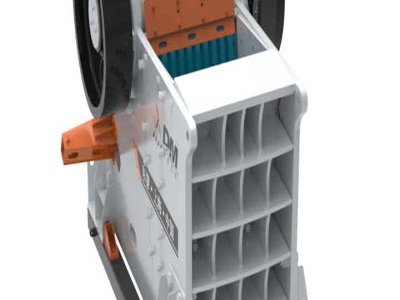

Specialty Lubricants for the Cement Industry

FOR THE CEMENT INDUSTRY Machines that are used in cement production are subjected to massive loads, strong vibrations and extreme temperatures. Together with gear and machinery manufacturers, we develop innovative specialty lubricants for crushers, mills, rotary kilns and roller presses. In doing this, we strive for highly

Availability, Reliability, Maintainability, and Capability.

But the root cause of the failure may lie in different areas than initially expected. Often deterioration, leading to economic failure, causes conflicts in the definitions of reliability, maintainability, and capability—real life issues are rarely simple and independent.

Protecting Concrete Tanks in Water and Wastewater ...

Dec 28, 2000· Another form of chemical attack occurs when sulfates in the water or wastewater react with the tricalcium aluminate in cement to form the expansive compound ettringite. This expansion causes internal stresses that cause the concrete to crack or crumble.

parts of raw mill in cement plant

In order to assure the kiln feed, we Raw Mill In Cement Plant,Cement Making Plant Crusher Machine Raw mill is made up of feeder part... Read more cement grinding mill spares in cement grinding plant YouTube

Top safety concerns in the manufacturing industry Plant ...

Plant Engineering Exposed wires, fatigued workers, poorly maintained equipment. Manufacturing facilities are riddled with risks, both hidden and out in the open. If you

Compression test on concrete

Generally concrete cubes are taken at the batching/mixing plant. The concrete mix if not transported and/or placed properly it will segregate and/or lose its workability. Segregated concrete forms honeycombs and is porous having large void content. 5% voids means 30% loss of strength and 10% voids means 60% loss of strength.

Primary Causes of Industrial Pollution | Earth Eclipse

Similarly, plants and wildlife have been badly affected in these regions. Notable cases are in particular nations in Asia and North America where industries have persistently released toxic wastes and poisonous gases into the environment. Lack of Effective Industrial Land use Planning; Industrial sprawl is a major problem in most industrial ...

Hazard and Operability (HAZOP) Studies

d. CAUSES These are the reasons why deviations might occur. Once a deviation has been shown to have a credible cause, it can be treated as a meaningful deviation. These causes can be hardware failures, human errors, an unanticipated process state (, change of composition), external disruptions (, loss of power), etc. e.

A Review On Environmental and Health Impacts Of Cement ...

one of the major contributors in global warming and climate change. Cement manufacturing is a highly energy intensive process, which involves intensive fuel consumption for clinker making and resulting in emissions. Beside Fuel consumption, the calcining process is a major source of emissions such as NOx, SOx, CO2, particulate matters etc.

Cement Wikipedia

A cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together. There are two main forms of cement: Geopolymer cement and Portland is seldom used on its own, but rather to bind sand and gravel mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete.

The Cement Manufacturing Process | Process Systems ...

Aug 15, 2017· The Cement Manufacturing Process Cement is a finely ground powder which, when mixed with water, forms a hardening paste of calcium silicate hydrates and calcium aluminate hydrates. Cement is used in mortar (to bind together bricks or stones) and concrete (bulk rocklike building material made from cement, aggregate, sand, and water).

Start condition monitoring to stop machine failures ...

Before attempting to start a condition monitoring program in your plant, identify what you want to achieve, such as increase machine uptime, prevent failure of machines that are crucial to a major ...

Common Causes of Machine Failures

Common Causes of Machine Failures. Particles such as dirt or wear debris can lead to threebody abrasion or surface fatigue, which results in the surfaces becoming pitted and scored. Adhesive wear involves two surfaces coming in direct contact with each .

Design, Modification and Analysis of Concrete Mixer Machine

concrete mixture which used to building construction and industry to make a concrete block, pipe, sheets, etc. it is observed that there is a failure of shaft and blade in mixer thus, deign modification and analysis of mixer have been done and presented.

Batching, Mixing, Transporting, and Handling Concrete ...

Batching, Mixing, Transporting, and Handling Concrete. setting becomes a persistent problem, a retarder may be used to control early hydration, especially in highcementcontent mixes. Mixture adjustments at the jobsite for air entrainment, and the addition of other admixtures, is permitted, followed by sufficient mixing.

Soundness Test of Cement | Le chatelier's mould appartus ...

Dec 16, 2017· Soundness test of cement: The change in volume of cement after setting or hardening is caused due to the "unsoundness of cement." The expansion of cement after setting causes disruption of the hardened mass and create severe difficulties concerning strength and durability of the structure.

CO2 Cement Production

Overview of Cement Production. Cement is an important construction ingredient around the world, and as a result, cement production is a significant source of global carbon dioxide (CO2 ) emissions, making up approximately percent of global CO2 emissions from industrial and .

Latest Posts

- مصنع معدات معالجة رمل الزركون

- جعلت الصين قائمة الحجر السعر كسارة

- الشركة المصنعة للمطحنة الدوارة ماهاراشترا

- كسارة المجاري الصغيرة

- أفضل مطحنة ضد التآكل

- كسارة الرمل بينغسون 900 السيارات

- الكسارات المخروطية المتنقلة المواصفات

- الفحم مصدر كسارة متنقلة في اليمن

- عملية كاملة من مصنع الاسمنت

- سحق الحديد الزهر

- تستخدم كسارة الدولميت في المملكة العربية السعودية

- ما هو طاحونة الأسطوانة العمودية

- مخروط محطم في النحاس المكثف

- كسارات حجر 100120

- قائمة الفك سعر كسارة بابوا غينيا الجديدة

- raymond mill photos india

- odernized gold mining machine manufacturer exporters

- stone crusher made from nigeria

- hammer crusher merk

- mobile cone crusher hydraulic circuits

- pelindian heap leaching

- silica sand washing plant malaysia

- the sand compaction pile method

- wheeled mobile crushing plant rcl

- wat is the use of battery in cement mill

- south africa gold vertical grinding mill

- gem stone grinding machines

- bar rolling mill stainless steel square bars

- marbonite tiles plant model price list

- equipment dominion 13x 18ball mill