oven to proses gold iron ore

The Hittites Iron smelting before the Iron Age

The Hittites appear to have produced an iron which could be reheated and worked, suggesting that their product was a form of wrought iron or some version similar to carbon steel. Charcoal was used as the reducing agent, layered with the iron ore in shallow hearths.

Gold Smelting PBS

No, because metal ores need to be heated to very high temperatures to produce pure metals — temperatures much, much higher than open fires can usually produce. Iron melts at 1800°C (3270°F) and gold melts at 1062°C (1943°F). Because iron has a higher melting temperature than .

Australian Iron Ore Jewellery | Free Shipping* | Australia ...

Shop Australian iron ore jewellery online with our huge range of necklaces and bracelets made from high quality gold, silver, palladium more! Discover more products that encompass Australian living at Australia the Gift. Domestic delivery is free on orders over 100, so start shopping today!

How Is Cast Iron Made? | Sciencing

Apr 24, 2017· Cast iron that has not cooled evenly produces a lowquality cast. Other problems faced during the cast iron process include contamination of the iron, gas porosity (the forming of bubbles in the iron), and problems with the fluidity of the metal. The casting process is an art that must be examined and experienced to be fully understood.

metallurgy What material is used to hold molten iron in ...

What material is used to hold molten iron in a furnace? Ask Question ... These are essentially stacks of alternating iron ore and charcoal sealed with a layer of clay on the outside which are allowed to burn over a long period with an air draught coming in through a hole near the bottom. This process produces a spongy mass of metallic iron ...

Iron Ore and Pellets

Vale is the world's biggest producer of iron ore and pellets, raw materials essential to the manufacture of steel. Iron ore is found in nature in the form of rocks, mixed with other elements.

GregTech 5/Mining and Processing Official Feed The Beast ...

This makes the Sifter optimal for almost every ore it can process.) Electromagnetic Separator: Another alternative to the Thermal Centrifuge/Sifter, the Electromagnetic Separator can only be used on Purified Crushed Ores that have Iron, Gold, or Neodymium as byproducts. It is energy intensive, but it is a good way of getting those specific metals.

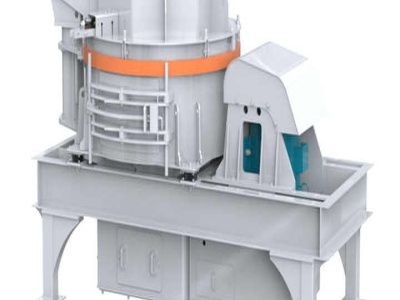

Limestone Gas Oven Processing Plant For Sale in China

2. The limestone gas oven processing plant sold in China contains granite, basalt gemstones, pebbles, bauxite, cement clinker, quartz sports stone, emery, ore, iron ore and other raw materials. The limestone gas oven processing plant is sold in China. Standard sand making products use only soft rock, and the disadvantages are less than 150Mpa. 3.

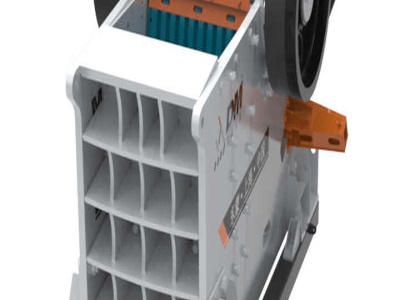

What's the process of iron ore mining? Quora

Jan 20, 2017· The first step involves the iron ore is crushed into small pieces. The obtained crushed ore in the send to the grinder followed by the scrubber. The major task of the scrubber is to remove waste from the ore and then categorize it into the sizes oversize, midsize and undersize. This is the process involved in iron ore mining.

SMELTING SILVER

the ore prior to smelting, particularly for lower grades of ore. Biringuccio does not discuss why roasting can improve a marginal ore. The more verbose Agricola (p. 273) explains that roasting can soften the ore prior to crushing, and will drive off undesirable sulfur3 and

Blast Furnace | FrackinUniverse Wiki | FANDOM powered by Wikia

Copper Ore x2 Copper Bar Iron Ore, Silicon Iron Ore x2 Iron Bar Lead, Carbon Gold Ore x2 Gold Bar Mineral Sample, Silicon Tungsten Ore x2 Tungsten Bar Carbon, Hydrogen Titanium Ore x2 Titanium Bar Mineral Sample, Silicon Trianglium Ore x2 Trianglium Pyramid Silicon, Mercury Prism Shard x2 Prisilite Star Oxygen, GravLiquid Aegisalt Ore x2

How to Remove Gold from Ore |

Remove Gold from Ore. Crush and mill the gold ore to dust like particles. Ore is put into the crusher, which breaks it up. Water is added during the process which, when mixed to the ore particles, creates a pulp. The ore in the pulp is then ground into smaller particles and pulverized into a ball mill.

Electrowinning and Smelting Resource Book

Electrowinning and smelting are the final stages of gold production. The concentrated gold solutions produced in the elution circuit (pregnant eluate and by the Sunrise Reactor, are passed through the electrowinning cells which converts the gold ions (charged gold particles) in the solution into solid gold.

India iron ore mining what can we expect next?

India iron ore mining ... Coke Oven Blast Furnace BOF and EAF. New Mining Projects Limestone Mine (Area 522 hectares) at Rewa Iron Ore ... Mining concessions through transparent online auction process Tenure of lease increased to 50 years from 20 to 30 years, with no provision for renewal District Mineral Foundation cess imposes additional cost ...

How the Iron Ore Market Works (VALE, RIO) Investopedia

Iron ore prices pretty much collapsed over the past few years, done in by oversupply and declining demand. But in 2018, prices were beginning to stabilize. Prices were above 125 per metric ton in ...

How Is Iron Extracted From the Earth? |

Magnetite and hematite are iron oxides; however, the extraction of iron from an iron oxide involves a series of steps that begins when mined iron ore is crushed into smaller pieces by a crusher and then washed. The second step in the process is calcination or roasting of the ore, which removes certain impurities, carbon dioxide and other substances.

iron ore mill adding gold flow process

Sudan Gold Mine Popular Wet Pan Mill Machine Grinding Mills For . Sudan Gold Mine Popular Wet Pan Mill Machine Grinding Mills For Sale, Find The grinding roller and grinding pan is one step injection molding,add the special in designing process flow for various ores beneficiation, including iron ore,

What is Smelting? (with pictures)

Jul 18, 2019· Smelting is a process for extracting usable ore from mixed deposits where people find ore bound with other metals, rock, and extraneous material. It is very unusual to find deposits of pure ore and this method allows people to separate out useful metals.

Efficient electric trolley ovens for sample drying

The range of Essa ® DO Series Drying Ovens are durable and designed for large batch handling. The units will improve your overall workflow and are proven to be reliable. They dry wet samples for chemical analysis quickly and efficiently, saving you time on what is often the most timeconsuming step in the sample preparation process.

Latest Posts

- سعر الذهب في كندا محطم

- آلة كسارة مستعملة في رايبور

- سحق النباتات تحت الأرض

- كيفية إنشاء تقرير عمل اللوجستية

- مصنع تعدين الذهب المحمول

- الحجارة الباريت في مصر

- سعر خط الأسمنت 150 طن يوميا

- مطاحن الكرة لالخزف أدوات المائدة

- من جهة ثانية محطة كسارة الفك الحجر

- سحق الدائرة المفتوحة

- الكرة صخرة محطم مطحنة

- الكرة المطاحن الكبيرة في مصر

- رمل السيليكا مصنع لتجهيز مخطط

- مصنعي آلة تكسير الحجر من أوروبا

- معمل تكسير الجرانيت الكامل من السعودية

- flowsheet for steel making html

- republic of congo silica sands

- how to use mobile rock crusher

- hidraulic cones crusher used with price

- ballast crushing machines

- gravity separator for placer gold

- construction companies in nigeria that does not have quarries

- martin s stone quarry bechtelsville pa pricing

- technology for gold mining machine

- sv12 milling machine

- pengertian quarry mine

- crusher machine bouxite

- stone crusher plant guideline

- limestone processing methods

- belt conveyor propelled