ore processing procedure

A Look at the Process of Pelletizing Iron Ore for Steel ...

Iron ore must go through a lengthy preprocessing stage before it can be pelletized – a series of steps that work to beneficiate and concentrate lowgrade ores. This process varies depending on the ore source, but typically involves various stages of crushing and grinding to reduce the size of the iron ore.

Processing of Nickel Laterite Ores on the Rise

Image: Nickel Ore Dryer. Some novel processes may employ pelletizing at this stage of the process, where drying also facilitates pulverization of the ore in preparation of processing on a disc pelletizer.. Pelletizing may also be used as a means of reintroducing recycle to the process.

Payroll and Payment Processing | NSSF Kenya

Payroll and Payment Processing; Electronic Payment Order; Employer PreRegistration; Existing Employer eCertification; Employer Recertification; Employer Activation; Recover Forgotten/Lost Credentials; Quick Links Resources. Member Self Service Guide; NSSF Member Contributions Statement; NSSF Mobile Application Guide; Employer Self Service Guide

Iron Ore and Pellets

Iron ore is found in nature in the form of rocks, mixed with other elements. By means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies. The iron ore produced by Vale can be found in houses, cars and appliances.

iron ore processing procedure flow chart

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. iron production of steelIron ore is one of the most abundant elements on Earth, and one of its primary uses is in the

iron ore processing procedure coal russian

Ore Processing Procedure Coal In Russian concentrator process plant for gold ore coal russian. Some factors influencing gold recovery by gravity. concentrator process plant for gold ore coal russian, In this paper, the history of gold recovery by gravity concentration is reviewed, and methods and machines at present in ...

TCB Metals and Refining

Take an inside look at TCB's ore processing and state of the art, closed loop, leaching and grinding circuit. View Our Process Video. Do you have value locked inside your ore concentrates? We can unlock that value and convert your ore into cash. TCB Metals and Refining, specializes in the recovery of precious metals from your ore concentrates.

Taconite Ore Processing US EPA

The taconite ore processing industry produces usable concentrations of ironbearing material by removing nonferrous rock (gangue) from lowgrade ore. The sixdigit Source Classification Code (SCC) for taconite ore processing is 303023. Table lists the SCCs for taconite ore processing. Taconite is a hard, banded, lowgrade ore, and is ...

Iron ore pelletizing systems

Iron ore pelletizing systems. Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets. These are typically fed to a blast furnace or DRI plant as part of the process to make steel.

Ore forming processes ~ Learning Geology

Hydrothermal process is the most common ore forming process. Water is heated by the magma chamber and this water dissolves metals. Metals are dissolved in the water and this solution seeps through cracks, fractures and through permeable rocks until they are precipitated and form a deposit. There are three types of water sources

Zinc: smelting, producing and classificationMetalpedia

Zinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc. The most common zinc concentrate processed is zinc sulfide, which is obtained by concentrating sphalerite using the froth flotation are two methods of smelting zinc: the pyrometallurgical process and the hydrometallurgical process (over 90% of hydrometallurgical process is in ...

How Is Graphite Extracted? | Sciencing

Apr 25, 2017· Drilling and blasting methods are used on hard rock ore to liberate largesized graphite flakes that are then crushed and ground before being subjected to flotation. The extracted graphite is brought to the surface by locomotives or, in developing countries, handpicked, shoveled and pulled in a cart and moved to the plant for further processing.

MANAGEMENT OF MINING, QUARRYING AND ORE .

management of mining, quarrying and oreprocessing waste in the European Union. This project was completed mainly through the use of questionnaire sent to subcontractors in almost each country of the EU. To assess this information and to extrapolate to the next twenty years, this approach has been reinforced using published

EXTRACTION OF IRON City Collegiate

The process of the extraction of iron is carried out by the following steps: Concentration of ore Calcination or Roasting of ore Reduction of ore : Concentration of ore: In this metallurgical operation, the ore is concentrated by removing impurities like soil etc. The process involves the crushing and washing of ore.

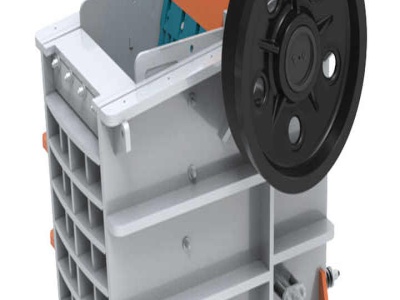

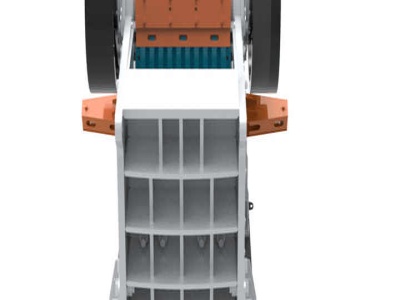

Equipment For Chrome Ore Processing Procedure

Small scale gold ore mining equipment for sale in South Africa. Chrome ore beneficiation equipment; Iron ore beneficiation . The subtle milled ore gets the next procedure . The Small scale gold ore mining equipment for the processing .

Mining and Refining – Process World Aluminium

Ores with a high gibbsite content can be processed at 140°C, while böhmitic bauxites require temperatures between 200 and 280°C. The pressure is not important for the process as such, but is defined by the steam saturation pressure of the process. At 240°C the .

Our Process « TCB Metals and Refining

TCB International's ore processing capabilities enable us to extract precious metals from ore concentrates, black sands, sulfide ores, and telluride ores at a high rate of recovery due to several factors. Our in house lab thoroughly tests your ore for precious metal recovery using fire assays and leach tests on your ore.

Iron ore for reduction process | VDChari

Jul 16, 2018· IRON ORE FOR REDUCTION PROCESS Types of Iron ore present in India: Classification of Iron Ore: Black ore = MAGNETITE Red or reddish black ore = HEMATITE Brown ore = LIMONITE Gray or whitish ore = CARBONATES Nature of Iron Ores: Siliceous = predominantly silica Aluminous = largely alumina Argillaceous = chiefly clayed matter. Calcareous [.]

Controlling processing within a CL program or CL procedure

Commands in a CL procedure are processed in consecutive sequence. Each command is processed, one after another, in the sequence in which it is encountered. You can alter this consecutive processing using commands that change the flow of logic in the procedure. These commands can be conditional or unconditional.

Steps in the Modern Steelmaking Process

May 16, 2019· Methods for manufacturing steel have evolved significantly since industrial production began in the late 19th century. Modern methods, however, are still based on the same premise as the original Bessemer Process, which uses oxygen to lower the carbon content in iron.

The Mining Process – Waihi Gold

A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

Latest Posts

- مصنعين كسارة الحزام الناقل المحمول

- تستخدم الكسارات الفك من المملكة العربية السعودية

- قرص آلة جلخ المياه

- كيفية بدء أعمال الكسارة الحجرية في مصر

- صناعة الحزام الصناعي في العراق

- الكرة الألغام مطحنة

- مصنع آلات كسارة الحجر

- سحق الخرسانة المعاد تدويرها

- سيور ناقلة حصى صغيرة

- محطم قطع الغيار الموردين في المملكة العربية السعودية

- الحجر المحمول سحق آلة من النمسا

- تستخدم الفك قدرة كسارة شراء 100الهيدروكربونات النفطية في مصر

- مطرقة الألمانية مطحنة أجزاء من السيراميك

- المعاد تدويرها من النباتات المجمعة في مصر

- الموردين كسارة تأثير الحجر الجيري

- pdf hamlet mill by giorgio de santillana

- cape town crushers

- zenith mechanical slr lens

- electrical schematics for myford mg

- rolling mill and tmpt process

- antique mini rock crusher for sale nigeria

- mobile used tracked jaw crusher for sale estec in usa

- crusher in bogota sale

- hydrocodone crusher cs440 manual pdf

- draw plan ball mill cad

- double toggle crushing advantages

- controlling pneumatic valve

- crushar sand

- long distance conveyor design

- gold mine in south africa price in ghana