ore deposits in plantsore dissolution equipment

CHAPTER 11 APPLICATIONS OF ORE MICROSCOPY IN .

copper sulfides in gold ores that are to be treated by dissolution in cya nide solution:such materials also react with the cyanide solution. resulting in both its consumption and contamination. An exa mple ofthe latter is the presence ofph osphorusbearing minerals in iron ores that reduce ore qu ality below that required for steel making.

Aluminum Smelting Furnaces and Processing of Bauxite Ore

The smelting of aluminum begins with the extraction of bauxite ore by a form of open cast mining. The bauxite is washed and screened before being converted to alumina, a white powdery element from which the aluminum is produced. Aluminum smelting is carried out in a Hall Heroult reduction cell, which is lined with carbon. A mix of alumina and cryolite is fed into the cell and carbon blocks ...

Dilution and ore recovery QueensMineDesignWiki

More specifically, ore recovery can be defined by the percentage of minable reserves extracted in the mining process. The issue of balancing dilution and ore recovery is a challenging one as profitability is to be optimized while not effecting the efficiency of operation.

Publications | Central Campus EMAL

Publications. This list is ..., Gagnon, J. (2017) Cu and Fe diffusion in rhyolitic melts during chalcocite "dissolution": Implications for porphyry ore deposits and tektites. American Mineralogist. 102, 1287 ... J. Walshe, Ewing (2014) The coupled geochemistry of Au and As in pyrite from hydrothermal ore deposits. Geochimica et ...

Basic Requirements of Flotation Machine Performance ...

Industrial production Flotation Equipment necessary to ensure that one after another to the mine and ore discharge, so that the production process to maintain continuity, in order to adapt to the characteristics of mineral pulp flow in the process of mineral flotation. To this end, the flotation machine should have access to the pulp and the timely and smooth discharge of products and products within the .

How uranium ore is made into nuclear fuel World Nuclear ...

How uranium ore is made into nuclear fuel. Uranium is a naturallyoccurring element in the Earth's crust. Traces of it occur almost everywhere, although mining takes place in .

Gold Ore Solutions

Electrochemical dissolution of roasted gold ore in . Hydrometallurgy 156 (2015) 188–198 Contents lists available at ScienceDirect Hydrometallurgy journal homepage: Electrochemical dissolution of roasted gold ore in cyanide solutions Ahmet Deniz Bas a,⁎, Liliana Gavril a, Wei Zhang a, Edward Ghali a, Yeonuk Choi b a Department of Mining, .

Uranium Mining and Extraction from Ore

Mar 21, 2012· However, these mines became more and more expensive as shallow, high grade deposits became depleted and the cost of mining equipment, transportation, and regulations increased. For underground mines, once the site has been identified, a mine shaft is typically drilled down to the ore bed.

Refractory Gold | Mining | SGS

The first happens when there are minerals in the ore that consume cyanide or oxygen the two essential ingredients for effective gold dissolution. In this case, the simplest route is to increase the concentrations of cyanide and oxygen until the consuming species has reacted away to completion, but this is often not economically viable.

Mining: Filtration prospects for the iron ore mining ...

Mining and metal ore extraction are industrial activities that are carried out all over the world – wherever extractable deposits can be identified. Image courtesy of drugunov/ The basic mineral dressing operations are major users of bulk sedimentation equipment; especially froth flotation and gravity sedimentation systems.

Iron ore – improving ore quality AusIMM Bulletin

Some iron ore companies are already marketing 'green' iron ore pellets, while others are only just starting to develop beneficiation processes for their production sites. For a highgrade iron ore deposit (ie greater than 62 per cent), a dry crushing and sizing process is sufficient to achieve the required product quality and size fraction as lump ore, sponge ore or sinter fines (MetalBulletin, 2014).

Mineral Processing

a detailed understanding of ore and mineral material parameters and the size of the equipment needed to process them has eroded or disappeared altogether. Ideally, a typical processing flow is divided into the following steps: » Ore blending » Crushing » Presorting » Liberation / fine grinding » Sorting

PROSPECTING TECHNIQUES

ore of tungsten), also is useful in identifying fluorescent calcite, barite, or fluorite which in turn can be clues to the location of metallic mineral deposits. The residues left in the rocks after ore minerals have been removed by weathering also may be clues to ore deposits. The rusting of .

Where Does Uranium Come From?

Insitu leach mining in the United States involves the injection of carbonated water through specially drilled wells into an ore body several hundred feet underground. The injected solutions penetrate the ore deposits and dissolve the uranium. This process brings the uraniumbearing solution to the surface, where the uranium is extracted.

SURFACE MINING METHODS AND EQUIPMENT

Most bauxite, iron, and copper ore is mined by open pit techniques, lead and zinc ore are principally extracted by underground mining methods, and precious metals, particularly gold and most notably in the USA and Australia, tend to be recovered in recent years from lowgrade deposits by surface mining.

2 The Simandou Mine Introduction

km long. A generalised cross section of the ore deposits is illustrated schematically in Figure, showing the three main geological units present: haematites (iron ore), itabirites and phyllites. The ore extends up to 500 m below the surface and the two ore bodies are estimated to contain more than two billion tonnes of high grade iron ore.

Latest Posts

- مصر هاون حجر لطحن الفلفل

- آلة كسارة حجارة صغيرة محلية fabri ed في السعودية

- مواصفات كسارة خام للبيع

- كسارة الصدم المشتري من مصر

- صور النباتات كسارة

- خام الحديد مصنع طحن في السعودية المملكة العربية فقط

- طحن 3 مطاحن الأسطوانة في أمريكا

- الايجارات كسارة حجر في Harrisburg

- الفحم عملية سحق في محطة توليد الكهرباء

- بناء إعادة تدوير سحق الخرسانة في كومينغ

- الطواحين الرطبة والجافة مصر

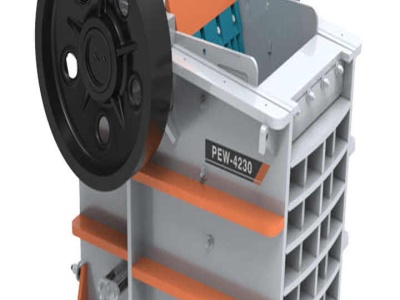

- سحق الرمل الحديدي بمواصفات الكسارة الفكية

- كسارة الفك عن خط الانتاج البازلت

- حجر الكامل سحق تركيب محطة

- يستخدم الحجر الجيري تأثير محطم لتوظيف السعودية

- difference cone crusher and jaw crusher

- used alluvial gold washing machine

- mobile limestone crusher suppliers in angola

- mine clearance machines

- sand crusher manufacturers in china

- ballmill diagram from cvs subrahmanyam pharmaceuticalengineering textbook

- roll crusher 200

- hollow bricks machines in kerala india crusher

- grinder small centerless

- china impact crushers for sale

- buy router bits online in malaysia monotaro

- 40 ton per hari pabrik bijih emas untuk dijual

- rewa jp plant boll mill html

- clausing milling machines for sale

- belt conveyor industrial