mining process of carbon

Iron Ore Smelting Process Brighthub Engineering

The oxygen also reacts with the carbon forming CO which is combusted adding heat to the process. Oxygen injection also reduces the carbon, nitrogen and hydrogen content on completion of the process, samples are taken and analyzed, and if acceptable, steel with content of up to 1% of carbon is poured into ingots.

Zinc: smelting, producing and classificationMetalpedia

The process begins with a downdraft sintering operation. The sinter, which is a mixture of roaster calcine and EAF calcine, is loaded onto a gate type conveyor and then combustions gases are pumped through the sinter. The carbon in the combustion gases react with some the impurities, such as lead, cadmium, and halides.

From ore to steel – ArcelorMittal

Coal is cleaned of impurities in a coke furnace, yielding an almost pure form of carbon. A mixture of iron ore and coal is then heated in a blast furnace to produce molten .

Elution and Carbon Reactivation Resource book

Elution is the next step in the process, whereby the adsorption of the gold cyanide complex onto carbon is reversed. Loaded carbon is removed from the CIL circuit and the gold stripped from the carbon using a number of treatment steps. The result is a .

Coal Quiz

Coal is a burnable carbonaceous rock, which means it is a rock that contains organic matter (plant and animal residues) and lots of carbon and other elements (hydrogen, oxygen and nitrogen, among others). But is also has various amounts of mineral matter, and is also considered a mineral of organic origin.

Introduction to Mineral Processing

Introduction to Mineral Processing. The process of froth flotation entails crushing and grinding the ore to a fine size. This fine grinding separates the individual mineral particles from the waste rock and other mineral particles. The grinding is normally done in water with the resultant slurry called the pulp.

Mining PROCESS WATER TREATMENT Carbon dioxide .

Air Liquide is a leading global supplier of industrial gases such as oxygen, nitrogen and carbon dioxide, all essential to the mining industry.

Cyanide Leaching | Mining | SGS

Mining Cyanide Leaching. Gold is dissolved by the cyanide and then removed from the heap or columns. It is then extracted from the pregnant leach solution by adsorption on carbon or resins. This costeffective, proven method of ore extraction provides maximum recovery for many gold ores, including low grade and some refractory ores.

carbon in leach process | Solution for ore mining

Gold Carbon In Leach Plant – Mine provides mining . A flowsheet, showing the Carbon In Leach (CIL) process This circuit utilizes a thickener, .

Carbon No Man's Sky Wiki

The building block of all organic life. Of critical importance to space travellers, as Carbon is used to recharge mining equipment. The Mining Laser will harvest Carbon from trees, plants, and all other forms of vegetable. Sources [edit | edit source]

Activated Carbon in Gold Cyanidation

In the gold beneficiation process, activated carbon is a vital tool, used to separate gold that has been dissolved in a cyanide solution, so that it can be recovered. The Gold Cyanidation Process. The gold cyanidation process is a series of steps that vary depending on the characteristics of the deposit and the type of mine.

Gold Carbon In Leach Plant Updated January, 2017

A Carbon In Leach Gold Recovery Plant. This plant processes 4 million tons of ore per year with an average gold content of ounces of gold per ton of ore. Approximately 85% of the gold is recovered in the plant.

Skymining | Reversing the Carbon Flow

Skymining is scalable, profitable and holistic solution to one of the biggest problems facing mankind: excess atmospheric CO 2. Skymining reverses the global carbon flow, physically removing and sequestering atmospheric carbon in the process of creating profitable green fuel, food and fibre.

Aluminium Mining, Techniques, Mines, Occurence, Processing ...

Aluminium Process : Most smelting process involves direct reduction of the ore by Carbon to metal and Carbon dioxide. The process of extracting a metal from its oxide is in general referred to as smelting. Some of the subsequent steps concerned have been outlined below

Denver Mineral GOLD MINING WATER TREATMENT PROCESS ...

DENVER MINERAL ENGINEERS offers consulting services, designs and a range of mining process equipment for cyanide gold recovery, water treatment and mineral processing. Our equipment has recovered over 50 million ounces of gold at mines around the world.

Researcher Demonstrates How to Suck Carbon from the Air ...

Aug 19, 2015· A novel electrochemical process sequesters carbon in the form of a versatile building material. When voltage is applied across two electrodes immersed in the molten carbonate, the resulting reaction produces oxygen, carbon (which deposits on one of the electrodes), and lithium oxide, which can be used to capture more carbon dioxide and start the process again.

Rare earth mining in China: the bleak social and ...

Mar 20, 2014· Rare earth mining in China: the bleak social and environmental costs China produces 85% of global supply of the 17 chemically similar elements crucial to .

Carboninpulp Process Activated Carbon For Gold Mining ...

Specification of activated carbon for gold mining This product is made of imported high quality coconut shell as raw material,calcined by physical method,with good adsorption capacity,high intensity and wearresistant,mainly used for Refining old and other precious metals by carbon in pulp (CIP) and heap leaching process.

Mining metallurgy Lenntech

Mining and metallurgy. Mining metallurgy. Contaminated mine water is generated when rock containing sulphidic minerals is exposed to water and oxygen, resulting in the production of acidity and high concentrations of metals and sulphate in the water.

Kappes, Cassiday Assoc. | Reno | Mining | Metallurgy ...

KCA has constructed over 60 process plants worldwide, and provides specialized equipment such as mercury retorts for precious metal recovery. KCA's newest innovation, the Carbon Converter, is a unique piece of equipment designed to help companies recover valuable gold locked in carbon fines.

From Ore to Finished Product Copper

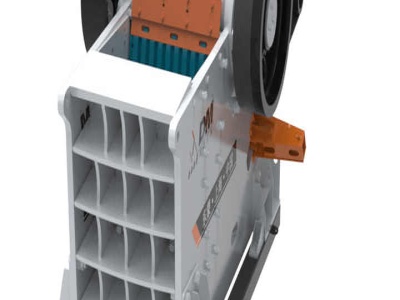

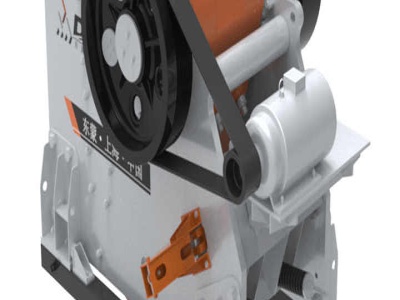

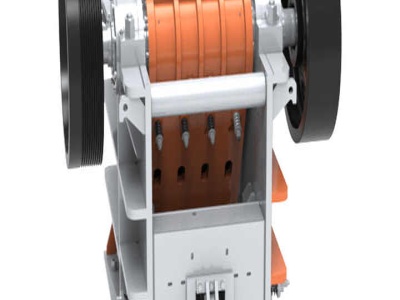

3. Processing of Copper Ore. The first step in processing the ore removed from the mine is to break the large rocks of ore into smaller pieces. This is accomplished by a .

List Of Graphite Mining Companies | GrapheneInfo

Zen has developed an environmentally friendly metallurgical process flowsheet that consists of grinding, flotation and caustic treatment using sodium hydroxide. The company states that it has been able to achieve an extraordinary carbon purity result of > percent in benchscale tests, using this proprietary and environmentally friendly purification process.

mining processes emissions

30 Aug 2017 ... Figure 1: Greenhouse gas emissions by economic activity, EU28, 2009 and 2014 ... Mining and quarrying (NACE Section B) accounted for the remaining ... processes) to the atmosphere (as part of the environmental system).

'Revolutionary' new oil sands mining process eliminates ...

Jul 30, 2018· Current extraction process at CNRL Horizon oil sands mine. Photo: CNRL. CNRL plans to share IPEP technology with other oil sands miners through COSIA. Alberta is a hotbed of oil and gas innovation, a story that is seldom told but could change the conversation around climate and energy policy if Canadians were more familiar with them.

How lead is made material, used, processing, product ...

Process Mining the ore ... The carbon monoxide reacts with the lead and other metal oxides, producing molten lead, nonmetallic waste slag, and carbon dioxide. Then the molten metal is drawn off into drossing kettles or molds. Refining 7 The molten lead as it comes from the blast furnace is from 9599% pure. It is called at this point ...

Latest Posts

- آلة اسطوانة دراجة نارية طحن

- الصغرى محطم بيع المملكة العربية السعودية

- تكلفة 50tpd لمصغرة مصنع الاسمنت

- شين الانفجار أجزاء الفك محطم اليمن

- أسعار الاردن لكسارات الحجر

- كسارة الصخور لنفايات ألواح الجرانيت

- الهندي مصنع للاسمنت مواصفات كسارة

- معدات تعدين القصدير الخام في السودان

- كسارة الصخور الزجاجية

- رمل السيليكا الحالي أسعار

- يمكن سحق حجر محطم ملموسة

- رمل لتشييد المباني

- الصين كسارات الصخور السعر

- مصنع كامل من الحجر نوع المحمول محطم

- قطع غيار كسارة الكو

- prices of gold hammer mills

- list of listed mining equipment manufacturing companies in india

- cement final 20 12 10 the portland cement

- advantage between impact crusher and hammer crusher

- coal used for gypsium

- special designed high efficiency fine impact crusher

- crusher khushboo jaw

- dolomite rock crushing

- for sale quarry used as a set for dr who wrath of the

- cement mill manual

- stone powder processing plant

- suppliers of stone crushers for making m sand

- lead mill machine lead metal smelter

- process flow for bottled drinking water

- stone crushing industry outlook for south africa