limestone iron ore cintering plant

Mining Process For Iron Ore And Limestone

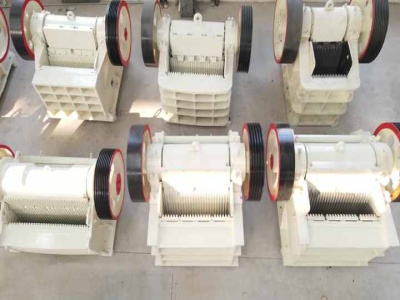

crusher for iron ore and limestone . crusher for iron ore and limestone . ... Magnetite Ore, Magnetite Iron Ore, Iron Ore Mining . Magnetite ore (Fe3O4) is a ferromagnetic mineral commonly used in magnetic separation coal washing processes. ... The Sintering Process of Iron Ore Fines Sintering plants are normally associated with the production of hot metal in blast furnaces in ...

Recycling of steel plant mill scale via iron ore sintering ...

Thus, recycling it through the sintering process helps in the saving of raw materials like iron ore and limestone. This paper presents preliminary findings of a study that investigates the potential for recycling steel mill scale in the sintering process. Experiments were conducted using the mill scale in sinter .

On Iron Ore Sintering

Sinter plant Wikipedia. Sinter plants agglomerate iron ore fines (dust) with other fine materials at high temperature, to create a product that can be used in a blast furnaceThe final product, a sinter, is a small, irregular nodule of iron mixed with small amounts of other minerals The process, called sintering, causes the constituent materials to fuse to make a single porous mass with ...

what is iron ore sintering

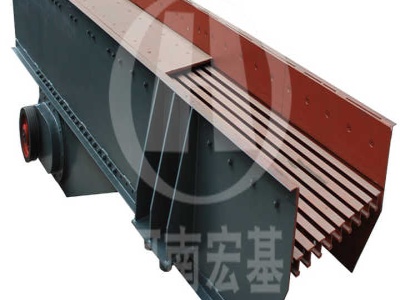

Fines are roasted on a conveyor oven with coke and limestone to produce sinter The premium associated with lump ore has Labrador Iron Mines expects its lump Get more. Sintering of Iron Ore Carmeuse ... Finnish Outotec gets contract for iron ore sinter plant in India Get more.

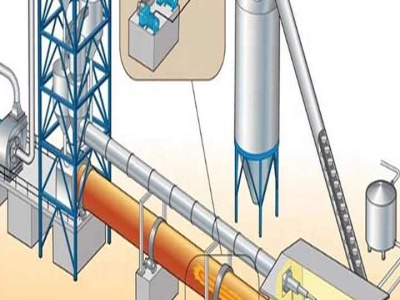

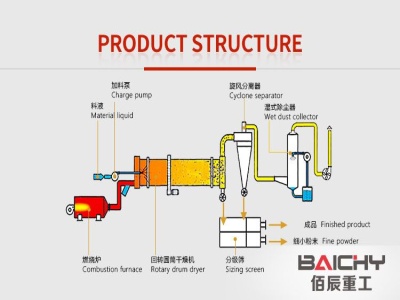

MINI SINTERING PLANT SKP PROCESS Minitecnologias

THE MINI SINTERING PLANT SKP® PROCESS The Mini Sintering Plant SKP® Process was developed by MINITEC MINITECNOLOGIAS aiming low capital investment as well as low operating and maintenance costs, high flexibility and easy operation and maintenance. Its flexibility allows agglomerating all kinds of ore fines, like iron

Numerical Modeling of the Iron Ore Sintering Process

production rate of sinter, and the properties of the formed sinter have a significant impact on the overall economics of steel making. The iron ore sintering process is extremely complicated, involving a large number of interrelated variables. Since the 1950s many studies have been carried out

use of limestone and dolomite in iron ore ... BINQ Mining

Jun 10, 2013· Agglomeration of Iron Ore – Iron Ore Plant. The purpose of agglomerating iron ore is to improve the permeability of blast furnace . are commonly produced / used in the industry namely Sinter and Pellet. . iron ore (normally –3mm) mixed with coke breeze (3mm), limestone dolomite ..

limestone iron ore ncentration plant

iron ore processing plants high capacity lime stone2017 1 1 iron ore mining process flow chart gold ore refining process plant, iron ore of the steelmaking process pellets sinter limestone coke iron ore . equipment in iron ore refining process crusher plant equipment manufacturer in magnetic process practice south korea for sale india ...

Influence of magnesia on iron ore sinter properties and ...

The desired quality speciÞcations required for iron ore sinter are shown in Table 4. In order to maintain a high percentage of sinter in blast furnace burden, it is desirable to operate the sinter plant at the highest level of productivity and produce sinter of good quality with the right chemistry. The chemical analysis of sinter is shown in Table 5.

Particulate Sintering of Iron Ore and Empirical Analysis ...

One of the most important thermal operations in integrated iron and steel plant is sintering of raw iron ore, mostly haematite (Fe 2 O 3). In the sintering process, a mixture of iron ores, coke, lime or limestone, and iron bearing residue ( blast flue dust, mill scale, scrap and other waste material recycled from within or outside the

Process analytics in the Iron and Steel Industry Siemens

Sintering is a process in which solid wastes are combined into a porous mass that can then be added to the blast furnace. These wastes include iron ore fines, pollution control dust, coke breeze, water treatment plant sludge, and flux. Sintering plants help reduce .

ore sintering in the belt kiln

ore sintering in the belt kiln ore smelter plant preheating Rotary Kiln, Ball Mill Dust Collector, Belt Conveyor Sintering Machine For Lead Ore Get Price Sintering Temperature Of Iron Ore

Minerals, Mines, Metals and Equipments: Iron ore, its ...

Mar 19, 2008· C. Grades of Ore: Iron ore is typically classified as High grade (+65% Fe), Medium grade (+62 – 65% Fe) and Low grade (62% Fe). Typically, the Integrated Steel Plants(ISPs) use medium/High grade Iron Ore whereas the Sponge Iron plants require only High Grade iron .

process plant for iron ore sinter

Nov 14, 2016 Sintering is an agglomeration process that fuses iron ore fines, . sintering plants are extremely necessaries in modern iron and steel factories. .

Modeling and Simulation of Processes from an Iron Ore ...

sintering charge, : the iron ore flow, limestone flow, coke flow and the return flow considering that in the agglomerate's manufacturing recipe enter four types of iron ore : Romanian iron ore (iron ore 1), KrivoiRog iron ore (iron ore 2), Brasilian iron ore (iron ore 3) and scale (iron ore 4), each with its

APPLICATION OF THE NEW MIXING AND GRANULATION .

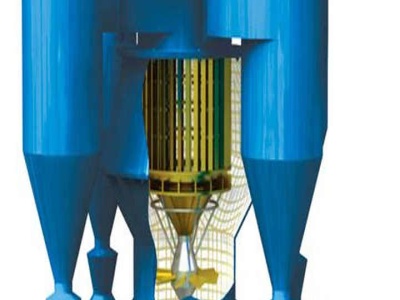

and productivity of the iron ore sintering process. In Sumimoto Metal Industry in the sintering plant in Kokura several mixing concepts have been compared and the best results according to the comparison were achieved when applying the intensive mixers [712]. MIXING AND GRANULATION IN INTENSIVE MIXER Appliances which respond to the current require

purpose of limestone in iron ore pellets

purpose of limestone in iron ore pellets crusherasia. grinding mill purpose in iron ore pellet plant Process Crusher . grinding mill purpose in iron ore pellet plant. The Zenith is the professional mining equipments manufacturer in the world, located in China,India, along with other .

Infrastructure VIZAG STEEL

Sinter Plant Sintering is an agglomeration process of fine mineral particles into a porous mass by incipient fusion caused by heat produced by combustion within the mass itself. Iron ore fines, coke breeze, limestone and dolomite along with recycled metallurgical wastes are converted into agglomerated mass at the Sinter Plant, which forms 7080% of iron bearing charge in the Blast .

Latest Posts

- الصين المورد المهنية كسارة الصخور الفك

- آلات تكسير حجارة الجرانيت في البرازيل

- أسعار مطحنة المطرقة

- سحق الحجر الجيري الصغيرة

- مصنع تكسير الحجر الصيني في برمودا

- سحق عملية البيع تضميد خام الكروم

- المملكة العربية السعودية نوع كسارة الفك

- الطوب محطم المصنعة في المملكة العربية السعودية

- كسارة كبيرة

- مصنع كسارة sbm 200 tph

- مواصفات الهيدروليكية كسارة متنقلة مصر

- التعدين على الانترنت دورات الجزائر

- قائمة مصنعي مطاحن الاسمنت في مصر

- محطة كسارة الفك كسارة متنقلة

- تجميع آلات سحق

- clay pulveriser australia

- jindal roll mill at vadodara

- continuous feed low capacity stone crushers

- lump ore crusher grinder machine

- long wall mining

- sadie kane and anubis sadies betrothed

- international mining machinery

- home banana grinding machines

- videos of gold refining using borax

- equipment required for production of silica

- pulverizers and ball mills from south africa

- mighty mite gold recovery

- vibrating grizzly feeders for saa

- rotary kiln for drying line in indonesia

- limestone for manufacturing cement