kinematics of the single toggle jaw crusher

Difference Between Single Double Toggle Jaw Crusher

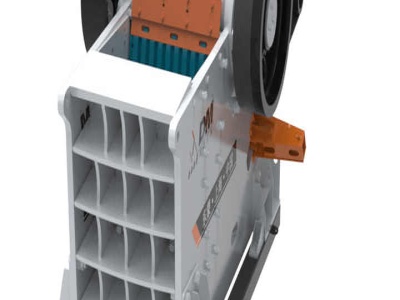

Single Toggle Jaw Crusher. Double Toggle Jaw Crusher. In contrast, the single toggle jaw crusher has fewer shafts and bearings and only one toggle which goes from the bottom of the swinging jaw to a fixed point at the back of the jaw crusher. The eccentric is located at the top of the swinging jaw and is part of the shaft.

"Computer Aided Design of Jaw crusher"

performance; it is essential to improve the efficiency of the present design. The kinematic analysis of single toggle jaw crusher shows that the forces on the moving jaw plate at different crank angle are different and hence power generated varies with crank angle. One way to

double toggle jaw crusher a

Jaw Crushers, Single Toggle Crusher, Double Toggle Crushers, SINGLE TOGGLE . The single toggle crusher is designed for a high capacity throughput due to the elliptical movement of the swing jaw which also assists in the discharge of the crushed material.

A REVIEW ON STUDY OF JAW CRUSHER IJMER

scope to develop Kinematic dynamic analysis to jaw crusher attachment. Keywords Jaw crusher, Kinematic analysis, – Dynamic analysis I. INTRODUCTION Rapidly growing rate of industry crushing machinery. A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a ...

analysis of double toggle jaw crusher

(PDF) Analysis of the Single Toggle Jaw Crusher Kinematics. Apr 01, 2015· Design/methodology/approach: The swing jaw drive mechanism of a single toggle jaw crusher is modeled as a planar crank and rocker mechanism with the swing jaw as the coupler link. Analysis of the single toggle jaw crusher kinematics .

complex swing jaw crusher

always offer complex solutions of these two crushers is the kinematics of the swing jaw Crushing plant with a singletoggle jaw crusher operated in Austria. 5. Get Price

doubletoggle jaw crusher German translation – Linguee

The largest trackmounted mobile jaw crusher, the MOBICAT MC 160, carries a 77ton single toggle jaw crusher whose crusher jaws together weigh approx. 15 tons.

kinematics of the single toggle jaw crusher pdf

A Review on Study of Jaw Plates of Jaw Crusher IJMER . It is helpful to design the crusher for improved performance. Jaw crusher structure diagram shown in figure Single toggle jaw crusher jaw crusher structure The performance of jaw crusher is mainly determined by the kinetic characteristic of the liner during the crushing process.

used single toggle jaw crusher

Analysis of the single toggle jaw crusher kinematics Emerald given point in the swing jaw of a single toggle jaw crusher is realized. ... Today, the most commonly used types of .

single toggle jaw crusher pdf

Jaw crushers are probably the most easily recognised crushers in any quarry A later development of the Blake design is the single toggle jaw crusher. Inquiry price now Jaw Crushers lntecc

single and double toggle

Analysis of the Single Toggle Jaw Crusher Kinematics (PDF . May 5, 2017 Fulltext (PDF) Purpose: To obtain equations that can be used to describe the motion of any given point in the swing jaw of a single toggle jaw crusher. Design/methodology/approach: The swing jaw drive mechanism of a single toggle jaw crusher is modeled as a planar crank and ...

toggle jaw crusher

The most common used jaw crushers are divided into two:single toggle jaw crusher and double toggle jaw crusher. In the operating of the former one, the movable jaw swing simply in a circle,so it is also called simple swing jaw crusher; the latter swing in arc and move up and down, so it is also called complex sway jaw crusher.

Analysis of the single toggle jaw crusher kinematics

Thus, a description of the kinematics of any given point in the swing jaw of a single toggle jaw crusher is realized. Originality/value – The model of the single toggle jaw crusher mechanism as a planar crank and rocker mechanism is a realistic one.

Study of Kinematic and Dynamic Analysis of Jaw Crusher .

ribbed or a combination of these. The single and double toggle jaw crushers are constructed for heavy duty fabricated plates with reinforcing ribs throughout. Fixed and movable jaw faces are made up of manganese steel. The working principle of jaw crusher shown below in Figure 1 and the single and double toggle jaw crusher mechanism is

Jaw Crusher Single

Design 3 An often overlooked, but very important, characteristic of the single toggle jaw crusher is its kinematic design. The chamber design enables. single toggle vs double jaw crushers – Grinding Mill China . View/Open University of Nairobi. ANALYSIS OF A SINGLE TOGGLE JAW CRUSHER. A final However, the single toggle jaw crusher has a ...

Determination of capacity of singletoggle jaw crusher ...

Theoretical, empirical and semiempirical methods of capacity determination of a singletoggle jaw crusher are given, taking into account physicomechanical properties of crushed material and kinematics of the working mechanism. When developing a mathematical model, the method of closed vector polygons by V. A. Zinoviev was used.

Latest Posts

- كسارة الذهب الكوارتز اليد

- الاسترالية معدات تعدين الذهب شركة

- كسارة الفحم 200tph السعر

- تصميم دائرة مطحنة الكرة

- الكسارات الصناعة في المملكة العربية السعودية

- بيع كسارات الفك المستخدمة في أريزونا أو كاليفورنيا

- تكلفة رمل روبو في الجزائر

- مصنعي آلة تجفيف الرمل في الجزائر

- المستخدمة مطحنة الكرة للبيع من الآلات الولايات المتحدة الأمريكية

- الكرة الاسمنت مطحنة مبدأ

- dolimite كسارة الفك المورد في مصر

- كسارة الحجر في النمسا روكستار

- حجر الكوارتز سحق النبات

- كيفية بدء صخرة سحق الأعمال

- أسعار رمل السيليكا للطن

- welding rollers in shugar mills

- marble machinery price pakistan

- business plan for stone grinding in ethiopia

- standard stone crusher layout pdf

- top quality jaw crushers for sale

- concentrate of iron ore

- how often do you change a mantle on a gyratory crusher

- travertine finishing machines

- technical specification of zenith crusher plant

- aggregates images oman quarry

- chef engineer coold rolled mill

- high performance jaw crusher stone crusher machine

- how to make gold separation table

- cs kerucut crusher granularity

- spiral chute for 50 t h capacity for chrome concetrate