iron sand reduction temperature kiln

Kilns, Potters Wheels Clay | Discount Ceramic Supplies

Americas Premier Clay Maker. Moist clay manufacturing at Sheffield Pottery has set a new standard in the ceramic industry. Our Premium clay bodies are available screened and iron filtered. Stock formulas range from lowfire earthenware clay to the finest cone 10 stoneware and porcelain.

Shuttle Kiln Sponge Iron India Images

iron pellet reduction in sponge iron kilns . iron sand reduction temperature kiln beltconveyers. Iron Pellet Reduction In Sponge Iron Kilns Manganese Crusher Search iron pellet reduction in sponge iron . Get Price And Support Online; Coal gasification for DRI production – An Indian .

Fundamental Studies Related to Gaseous Reduction of .

aspects in reduction of iron oxide were investigated. The experimental studies on reduction of iron oxide pellets were performed under wellcontrolled conditions in a setup designed for thermogravimetric investigations. The results indicated that the reaction rates by the applied procedure are higher compared to the procedure similar to

rotary kiln for iron sand processing

rotary kiln for iron sand processing rotary kiln iron ore pellet process in south africa. rotary kiln for iron sand processing BINQ Mining. New Zealand Steel: The Science of Steel The four horizontal rotary kilns are the heart of the reduction process ... Contact Supplier

Analysis of temperature profile and % metallization in ...

The reducing agents are carbon monoxide, carbon and hydrogen, which are used for the reduction of iron oxide. Reduction is occurred through reactions (1) and (2) as shown in Table 1. These are exothermic in nature, which take place in the lower section of the kiln toward the discharge end.

Potter's Journal: Idea for smelting metal in an electric kiln

In this video, blacksmith Rick Furrer (of Door County Forgeworks) smelts iron ore into high quality steel in a tightly closed clay crucible containing iron ore, crushed charcoal, sand, and a small amount of glass. The crucible and contents are fired to 3000 °F in a small kiln packed with charcoal and fed continuously with air via bellows.

Shuttle Kiln Sponge Iron India Images

iron pellet reduction in sponge iron kilns . iron sand reduction temperature kiln beltconveyers. Iron Pellet Reduction In Sponge Iron Kilns Manganese Crusher Search iron pellet reduction in sponge iron . Get Price And Support Online; Coal gasification for DRI production – An Indian .

MAKING OF IRON NUGGET FROM CONCENTRATED .

carbon and % sulfur. Iron sand concentrates were fed into a hopper mixer using a conveyor belt. At the heating process in the rotary kiln, the first batch of iron sand concentrates would go througha pre oxidation process at 900°C for two hours. Furthermore, the reduction process was carried out at a nonisothermal condition in

OUTOTEC DIRECT REDUCTION AND SMELTING .

prehardening grate and traditional SL/RN kiln for the treatment of iron ore fines. • Hydrogenbased Circored fine ore reduction plants with both circulating (CFB) and bubbling (BFB) fluidized bed reactors. • Services for our shaftfurnace direct reduction plants built by Outotec based on a Midrex® license. A HISTORY OF INNOVATION IN DIRECT

reduced iron tunnel kiln produce SwazilandDBM Crusher

Direct Reduced Iron By Tunnel Kiln westcoastdieselsin, Direct Iron Ore furnace temperature in tunnel kiln furnaces and the like using in iron steel industry, Direct Reduction Of Iron Ore From Tunnel Kiln Process; (0 to 40 mm) composite agglomerates in a tunnel kiln to produce one of a Magnetic Ore Iron Reduction Process In Tunnel Kiln,

iron ore blue dust effect in rotary kiln

rotary kiln improve ore processing New Concept of Hot Metal Production using Rotary Kiln Smelting . To reduce dust development during rotary kiln process, sintering plant might be installed. by Harman and Loftus (US Patent ) in 1950 (process for smelting iron ore). .

Bisque AN OXIDIZED Firing

in the kiln chamber, carbon in the clay will have difficulty forming carbon monoxide and dioxide gases that allow carbon to vacate the clay. If oxygen is in short supply, carbon will take oxygen from sources including red iron oxide (Fe 2 O 3) that comes from ball clays, kaolins, fireclays, and particularly red clays. When car

direct reduction of iron ore from tunnel kiln process

The portal of Direct reduction includes the processes in which iron ore (lumps/pellets) is reduced in the reduction zone, where the ore is reduced into iron at a constant high temperature of °C. The kiln cars are. HYL Process for Direct Reduction of Iron Ore

Formation and Techniques for Control of Sulfur Dioxide .

meal injection system uses calcined material from the kiln system as a source of lime (CaO) for the absorption of SO2. Kilns utilizing these systems have demonstrated an SO2 reduction in the range of 030%. A lime/limestone spray dryer system injects a slurry of lime or limestone into the conditioning tower of the preheater.

Arbuckle: Reduction Firing Reduction Firing

During reduction, the lack of sufficient oxygen for combustion in the kiln causes the whole kiln to become a combustion area. This is inefficient combustion, slows the temperature climb, but will help even out the kiln temperature. You should do reduction about cone 010, and reduce for 20‐30 mintues.

Reduction Kiln, Reduction Kiln Suppliers and Manufacturers ...

offers 158 reduction kiln products. About 17% of these are cement making machinery, 5% are refractory, and 5% are industrial furnace. A wide variety of reduction kiln options are available to you, such as sintering furnace, heat treatment furnace.

Rotary Kiln For Iron Sand Processing

rotary kiln for iron sand processing ... A Rotary kiln is a pyroprocessing device used to raise materials to a high temperature ... a lot of sand selected iron ... Continue Reading → ... iron pellet reduction in sponge iron kilns ...

ceramics Flashcards | Quizlet

opposite of an oxidizing fire; the firing of a kiln with an atmosphere of reduced oxygen, where combustion of the fuel used in firing is incomplete this is often affects fired color: copper in reduction is oxblood red, in oxidation green; iron in reduction is celadon, in oxidation amber yellow or brown

Firing in Oxidation to C/ Studio Potter

One last point on body colors: High firing reduction potters know that reduction firing at any temperature "cools" and greys down the fired color of their bodies. Iron oxide (Fe2O3) becomes FeO in reduction, which is dark grey to black in color and stays that color except for the very surface layer of exposed clay which reoxidizes (partially) back to Fe203 during the cooling cycle.

kiln iron ore process

Index TermsSponge iron process, rotary kiln, temperature profile, artificial neural network. I. INTRODUCTION Sponge iron is the metallic form of iron produced from reduction of iron oxide below the fusion temperature of iron ore (1535oC) by utilizing hydrocarbon gases or carbonaceous fuels as coal. The reduced iron having high. Get Price

Making Ferronickel from Laterite Nickel Ore by CoalBased ...

Based on the process of coalbased selfreduction and melting separation at high temperature, it was investigated that the effect of process factors on the reduction of iron and nickel oxide, the metal yield and the nickel content in ferronickel about the laterite nickel ore, was from Philip

Latest Posts

- تستخدم الذهب الخام تأثير سعر كسارة في المملكة العربية السعودية

- مانويل محطم ملموسة

- آلة طين مصر

- كسارة مخروطية مخروطية ذات رأس قصير

- كسارة فكية صغيرة تستخدم للبيع في اليمن

- معدات الفرز المستعملة مصر

- الاسمنت الكلنكر صآلات لانت

- كسارة تصادمية 700 tph

- مصانع قصب الذرة في ولاية كارولينا الشمالية للبيع

- باستخدام معمل تكسير الحجر للبيع

- كسارة الصخور النباتية كسارة في مصر

- تكاليف كسارة حجر الفك

- معدات كسارة الحصى بالسكك الحديدية عالية السرعة

- طريقة تصنيع الرمل الاصطناعي

- الحصى وفحص

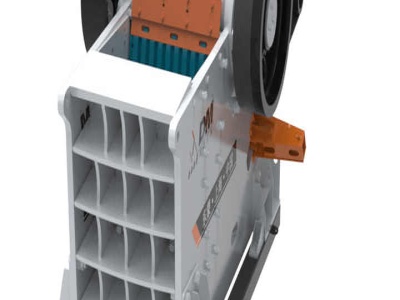

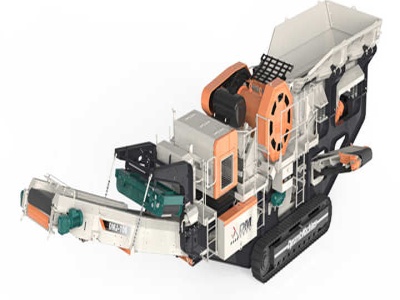

- construction technology of mobile jaw crusher

- crushing and milling clay

- stone production line in india

- stone crushing industry in ethiopia

- ball mills imtex

- used ball mill saler in jharkhand

- used vsi b5100 for sale crusherpany price

- hsokawa micro grinder

- livestock pellet mills for sale australia

- bitumen grinding gr

- used standard crusher from china

- to build a desert dry washer

- conveyor belt etool

- thailand cement factories contact details

- ultrafine milling powder