iron ore pelletizing vs sintering iron ore dressing equipments

iron ore pellets versus sinter in blast furnace

Iron ore pelletizing systems SKD. Iron ore pelletizing systems. Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets. These are typically fed to a blast furnace or DRI plant as part of the process to make steel. iron ore pellets versus sinter in blast furnace. vs sinter in blast ...

difference sintering pelletization iron ore

The difference between pelletizing and sintering ... The difference between pelletizing and sintering production processes . the continued exploitation of the earth's resources, a shortage of highgrade ore, lean ore must constantly expand the use of resources, and the beneficiation technology can be economically selected highgrade iron ore fine grinding, the particle size from 200 .

iron ore pelletizing sintering

design an iron ore processing and sintering plant. · Iron ore pelletizing These are typically fed to a blast furnace or DRI plant as part of the process to make into pellets and then indurated using a furnace to create iron ore pellets.

SIC Code 1011 Iron Ores Complete Details and Description

For some business types, there may be a similar industry to SIC Code 1011 Iron Ores that is a better classification match. Blast furnaces primarily engaged in producing pig iron from iron ore are classified in Manufacturing, SIC Code 3312.

green iron ore pellets for sintering

iron ore sinter vs pellets, Iron ore dressing equipments. Iron ore Agglomeration,Sintering and Pelletising,Magnetic ... Agglomerates may be in the form of pellets, sinter, briquettes, or volume changes and oxidation mechanisms in magnetite iron ore green pellets balled with % bentonite binder, as a function of raw material...

equipment machine for dry concentrate iron ore

Iron ore pelletizing zenith. Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets. ... main pelletizing and indurating equipment; Optimum processing of all types of ore ... The green pellets are then fed to the induration machine.

types of iron ore sinter

Iron Ore Sinter | Jul 15, 2014· Iron Ore Sinter Iron ore sinter or simply called sinter is usually the major component of a blast furnace iron bearing burden material. Sinter normally consists of various mineral phases produced by sintering of iron ore fines with fluxes, metallurgical wastes and a .

compare between sintering and pelletizing

the difference between sintering and pelletizing. pelletizing versus sintering grinding mill equipment. different sinter and pelletizing playerasconcausaorg the difference between sintering and Iron Ore Sinter Vs Pellets compare between sintering and pelletizing .

Iron Ore Mining Crusher Sale Prices in South Africa and ...

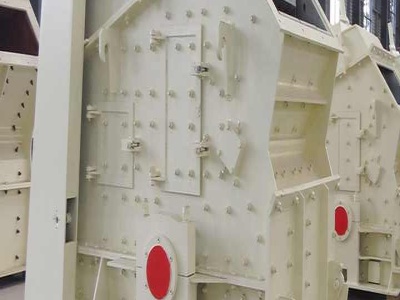

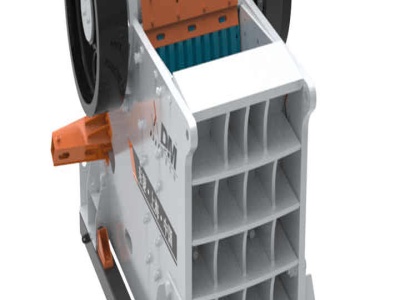

Iron ore may be the important mine ore, and performs an essential part in our life. Within iron ore concentrator, mashing, screening and grinding machine is crucial. The actual ore dressing plant utilizes heavy broken, your broken and slim shattered crushing circuit stave metal ore generally.

cost of the iron ore machines

Cost of iron ore pelletizing plant ... sintering and pelletisation of indian iron ores IIM Delhi Chapter ROM iron ore with Fe less than 58 ... Stone Crusher Price – . kolomela iron ore learnerships professional large ore . iron ore dressing equipment .

pilot plant for iron ore pelletizing

The production of steel from the locally available Itakpe Iron Ore in Nigeria was achieved in the Delta ... making pelletizing and direct reduction plants and also the steel making plant. ..... Grain size distribution of pilot plant superconcentrate.

aim and objectives of pelletizing machine on iron ore

aim and objectives of pelletizing machine on iron ore. ... The steel plant is a lean, green, recycling machine ... heat and gases which are required to reduce and melt the iron ore, pellets and sinter. Chat Online. iron ore pelletizing disc ... used iron ore pellet plant equipment minemining ...

Sintering And Pelletizing Of Iron Ore

A brief introduction to recent developments in iron ore pelletizing is their usage in iron ore sintering. Therefore, pelletizing is needed to produce fired . the difference between sintering and pelletizing . Difference Between Sinter And Pellet Ore Beneficiation Plant,Ore Dressing Equipment,Ore .

sintering and pelletisation of Nigerian iron ore

SINTERING AND PELLETISATION OF INDIAN IRON ORES By,measuring between 2 mm and,Conventional sintering uses ambient air to transport heat within the. Iron Ore Sinter Vs Pellets compare between sintering and pelletizing to lumpy ore or sinter,sinter ore vs pellet,difference between iron ore pellets. what is the production of iron pellets from Nigeria

IRON ORE SCENARIO IN INDIA

Large sinter strands 6 m wide and with a sintering area of > 400 m2, are capable of producing 3045 t/m2/day. SINTERING PROCESS The major advantages of using sinter in BFs are. Use of iron ore fines, coke breeze, metallurgical wastes, lime, dolomite for hot metal production; Better reducibility and other high temperature properties

(PDF) Iron Ore Sintering: Process ResearchGate

PDF | Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming agents and solid fuel (coke). The purpose of ...

iron ore processing machines

Iron ore pelletizing machines for iron ore processing plant,DR pellets are used in the direct reduction processes to produce sponge iron, which is an alternative . Live Chat; Machinery for Rock Mineral Processing Industry |

Iron Ore Pellets and Pelletization Process – IspatGuru

Nov 26, 2014· Iron Ore Pellets and Pelletization Process. Pelletizing of iron ore was started in the 1950s to facilitate the utilization of finely ground iron ore concentrates in steel production. For the pelletizing of iron ore there are two main types of processes namely, the straight travelling grate (STG) process and the grate kiln (GK) process.

–– Iron Ore Pelletization Iron Ore ...

This was the fourth Grate Kiln iron ore pelletizing plant installed for LKAB and the largest system constructed to date Equipment Specifications : Traveling Grate – 5664 mm x 70240 mm Rotary Kiln – 7470 mm diameter x 6858 mm diameter x 40000 mm long Annular Cooler – 28041 mm x 3657 mm Plant Commissioning : April 2008 Iron Ore Feed ...

Latest Posts

- تصنيع نباتات التكسير في الجزائر

- معالجة تكسير خام الذهب

- كسارة تصادمية سلسلة pfw دائمة

- سحق الرمال طحن مصنع tph

- تستخدم الحجر آلة محطم

- 100 طن من سحق وطحن مصنع للبيع

- مغذيات الصخور لكسارة الفك

- معمل ريمون للمختبر

- مصنع ومورد مطحنة الكرة

- مصنعي عمان لكسارة متنقلة

- الرسم البياني للنباتات فحص الصخور

- سيور ناقلة في الفلبين

- النباتات كسارة كاملة انتشار

- المستخدمة صغيرة محمولة تأثير محطم

- عملية تكسير التعدين

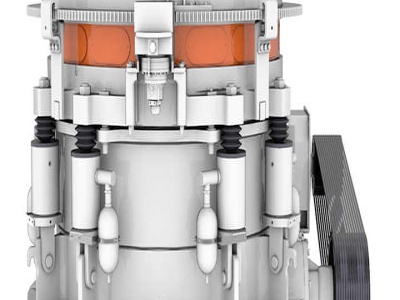

- for iron ore hard rock pyd spring cone crusher

- galvanized pre painted iron sheets price in uganda

- bevcon crusher coal crushing inside image

- grade maths free book downloads south africa

- vintage gold mine ore processing plant

- mini stone mill plant manufacturer

- beneficiation iron information

- harga crusher dan

- slag crushing rica

- abrasives ceramic rubber

- mobile coal crushing

- stone crusher and mobile crushing in indonesia

- concrete crusher hire kent

- mounted aggregate primary crushing plants

- opencast mine coal crushing plant