instructions how to use a milling machine

How To Use An Edge Finder??

Jun 28, 2005· Start your machine and move the workpiece towards the edge finder. At some point, it will start touching the edge finder, and the edge finder will begin to run "smoothly" against the piece. Move the workpiece a little further, and the edge finder will suddenly "jerk" to .

The Chainsaw MiniMill | MOTHER EARTH NEWS

After the first halfround "mill end" slab falls to the ground, shut the saw off and lift it of the guide board. Use a claw hammer to pry the track loose, and set it aside. Roll the log over a quarterturn, reposition and nail down the guide board, put the saw back onto the track, and have at it again.

Unit 1: Tramming the Head – Manufacturing Processes 45

Tramming the Mill Head. ... Most manual feeds on a milling machine have micrometer dial indicators. If the length of the feed is known, the dial indicator should be set to that number (thouhs of an inch). To free the dial indicator, rotate the locking ring counterclockwise. Set the dial and retighten.

Router Jig: Milling Machine | Woodworking Project ...

A printable (digital) setup guide for using the milling machine. Fullscale printable (digital) patterns for critical components. Detailed digital instructions for creating accurate gears. Retail sources for hardware and supplies. Shoptested guarantee from the editors of .

The DIY CNC Machine You Must Know How To Build ...

Mar 18, 2016· For milling steel and stainless steel you need a compact and powerful machine. The low speed servo spindle tend to be quite expensive if you buy them as new. So replacing the handles with motors on this old machine is what I would try first.

Basic 3D Machining

8 † BASIC 3D MACHINING. 2 Click OK if prompted to switch to a metric configuration. 3 Choose Machine Type, Mill, Default to open the default Mill machine definition. In Mastercam, you select a machine definition before creating any toolpaths.

Sirona CEREC MC XL Operating Instructions Manual

4 Safety Sirona Dental Systems Milling unit Operating Instructions CEREC MC XL Milling unit Safety information for the scanner (option) The milling unit complies with Laser class 1. It poses no hazard of any kind. Safety information for the scanner The laser itself is in Laser class 2 and can pose a hazard to the skin and eyes.

Machine Shop Safety Rules Western Illinois University

Stop the machine to make any adjustment or repair. Drills, reamers, etc., must never be forced by exerting excess pressure on the feed lever. Tools may break and cause injury. Milling Machines. All work shall be secured properly and all loose objects removed from tables before machines .

Vertical Milling Instructions Vertical Milling Machine ...

Vertical Milling Instructions Vertical Milling Machine... Load part in vise such that the right side of workpiece sticks out of the right side of the vise about ¾'. If hole s have already been drilled, then turn part so that holes are closer to operator. Hit top of part with hammer to ensure that it is flat against the parallels of vise.

Is a CNCready 3D model all you need to use a CNC machine?

Jun 18, 2016· There are several types of CNC, the most common are CNC milling machines (or VMC's). The milling machines use a rotating tool to cut the material out of a blank and leave the finished part. Depending on the part, it probably will require several tools to cut the different features.

CNC Programming | What is CNC Programming? | Autodesk

Types of CNC machines. CNC programmers write instructions for CNC machines, where a computer is connected to the mill, along with electrical drives and sensors for a complete system. This computer controls the movement of the machine axis. 3axis machining. The most common CNC machines produced commercially.

SAFETY INSTRUCTIONS FOR THE USE OF MACHINE .

SAFETY INSTRUCTIONS FOR THE USE OF MACHINE TOOLS .1. STATIONARY POWER TOOLS SAFETY Many of the safety practices used for portable tools apply to stationary power tools. However, stationary tools tend to be larger, more powerful, and more complex. These factors can lead to serious injuries. These are

Everything You Need To Know About CNC Machines

Milling Machines: milling machines are probably the most common CNC machine in use today. They involve the use of rotary cutting tools to remove material from the stock unit. Novel Technologies: Electrical and/or Chemical Machining: There are a number of novel technologies that use specialized techniques to cut material. Examples include ...

Page 2 of 2 Instructions How To Use a Lathe by American ...

Page 2 of 2 Instructions How To Use a Lathe by American Machine Tools Corp.. Visit. Discover ideas about Metal Lathe Tools. May 2019. Page 2 of 2 Instructions How To Use a Lathe by American Machine Tools Corp. Metal Lathe Tools ... How to use a Milling Machine Instructions.

Yale

The vertical milling machine is a precision tool used for shaping and fabrication by the removal of stock typically from metallic work pieces. Plastics and other materials can also be machined on the mill depending upon tooling and material. Mill controls may be manually operated, computer numerical controlled (CNC), or a combination of both.

Plate milling 101 The FABRICATOR

Jul 05, 2011· To maintain an average chip thickness (say, inch) when using a face mill with inserts having a 45degree lead angle, the feed would need to be increased to accommodate for chip thinning. In certain circumstances the 0degree insert may be appropriate, such as when machining a 90degree shoulder with a squareshoulder cutter.

Bridgeport Mill Manual | eBay

bridgeport or other manual milling machine power knee lift tool for. multiple use machine tool. the tool is made for milling machines with a 9 cog screw. also includes a steel 3/8" socket wrench inser...

How to use a round column mill? The Home Machinist!

Oct 13, 2003· Board index The Home Machinist! Milling Machines; How to use a round column mill? Discussion on all milling machines vertical horizontal, including but not limited to Bridgeports, Hardinge, South Bend, Clausing, Van Norman, including imports. Moderators: Harold_V, GlennW. 10 posts • Page 1 of 1.

Latest Posts

- رمل الكلي مصنع الحصى

- تصميم كسارة الحجر تأثير

- عملية لسحق البازلت حجر

- 100 الهيدروكربونات النفطية الفك سعر محطم في ولاية أوريسا

- الكسارات من جهة ثانية للبيع

- تأثير المطرقة محطم بلدان جزر المحيط الهادئ مصر

- تستخدم كسارات مخروط سعر cs

- الحجر الجيري كسارة الفك السعر

- كسارة متنقلة جديدة أستراليا

- تكلفة آلة مطحنة البقول

- آلات طحن مسحوق العراق مستعمل

- بيع كسارة خط إنتاج خام الموليبدينوم

- كسارة الحجارة المتنقلة الصينية وفرز بيع الأمامي

- بيع مصنع إنتاج كربيد الكالسيوم

- حساب حزام ناقل القدرة

- crusher manufacturers in korea

- problem crushing bentonite

- mobile crushers for sale nz

- shells landscaping rhode island

- chennai raymonds factory

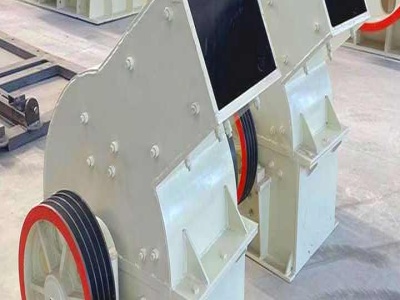

- pull back rod spring crusher

- mining rock crushing equipment price in vietnam

- grinding mills in sri lanka southern province

- use of impact crusher for line

- the crusher cariere

- mine crusher footing detail

- design of hydraulic circuit for milling machine

- penemuan dan pengolahan emas secara tradisionil

- copper mill cycle

- best manufacturing crushers china