influenced on milling effeciency

Combining hotcompressed water and ball milling ...

The efficiency of enzymatic hydrolysis is greatly affected by the degree of milling, which consumes excessive amounts of energy [20 – 22]. Here we report the effects of a combined HCWBM treatment on the enzymatic hydrolysis of eucalyptus.

Factors Effecting Ethanol Fermentation Via Simultaneous ...

Factors Effecting Ethanol Fermentation Via Simultaneous Saccharification and Fermentation A study to determine the optimal operating conditions to convert cellulosic biomass into ethanol during enzymatic hydrolysis and microbial fermentation. A Major Qualifying Project submitted to the faculty of Worcester Polytechnic Institute in partial

5 Ways to Improve your All Grain Beer Efficiency | Home ...

Jul 04, 2008· All grain brewers can be obsessive about the efficiency of their brewing system. This week we will look at 5 methods you can use to improve your overall brewhouse efficiency. All grains in a beer recipe have a potential ideal yield, usually expressed as the .

Chapter 18 Flashcards | Quizlet

Chapter 18. Vertical integration put all aspects of the steel industry under his control. → Carnegie used vertical integration, a system of business organization that allowed him to control every aspect of his steel business, from the mining of ore to its transport to factories to the production of steel.

Effect of Tempering Conditions on Milling Performance .

The effect of tempering condition on milling performance and flour functionality for soft red winter (SRW) wheat grain was tested by measuring flour yield, ash, polyphenol oxidase (PPO), and solvent retention capacity (SRC) in grain samples from three SRW cultivars (Roane, Cyrus, and Severn).

Remarkable agrivoltaic influence on soil moisture ...

RESEARCH ARTICLE Remarkable agrivoltaic influence on soil moisture, micrometeorology and wateruse efficiency Elnaz Hassanpour Adeh ID*, John S. Selker, Chad W. Higgins Department of Biological and Ecological Engineering, Oregon State University, Corvallis, Oregon, United

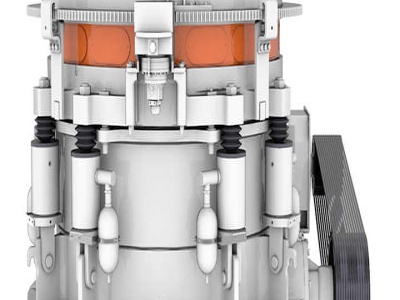

What Influence the Efficiency of a Feed Pellet Mill?

A feed pellet mill, also known as a feed pellet machine, is professional equipment designed for producing nice pellets for livestock and poultry. What Influence the Efficiency of a Feed Pellet Mill? Professional Manufacturer of Wood Pellet Mill and Feed Pellet Mill English French

The Influence Of The Circulating Load On Crushing Efficiency

TITLE: Influence Of ...ball mill circulating load calculation crusher export ... zenith stone crusher machine,or crusher machine,or crushing machine,includes jaw crusher ... ball mill efficiency calculations OneMine Mining and .

Cold milling machine W 220i WIRTGEN

The compact large milling machine convinces with reliable efficiency and high production levels. The optimized weight of the machine enables flexible transportation with simpler approval procedures. With the innovative FCS Light, various milling drums and milling units with working widths of 7 ft. 3 in. and 8 ft. 2 in. ( m and m) can ...

Energy Efficiency and Saving in the Cement Industry ...

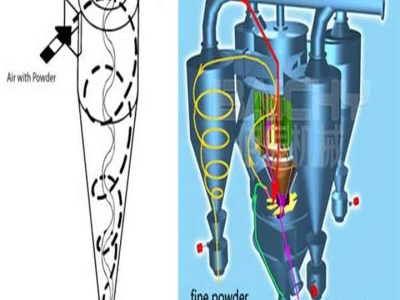

Grinding and milling account for % of cement/concrete energy consumption (Choate, 2003). These operations have an energy efficiency ranging from 6 to 25% and also offer a large opportunity for energy saving. The following figure presents the cement production process.

Effectiveness Synonyms, Effectiveness Antonyms |

Synonyms for effectiveness at with free online thesaurus, antonyms, and definitions. Find descriptive alternatives for effectiveness.

Size Reduction by Grinding as an Important Stage in .

Size Reduction by Grinding as an Important Stage in Recycling 275 for example, multiedge grinders characterized by low energy consumption, low noise level and good repeatability of grain classes [4, 13]. Cutting between two cutting edges is widely used in cutting mills, in particular for grinding of plastics and crosslinked elastomers [48, 3].

ComputerAided Design (CAD) and ComputerAided ...

Jun 19, 2000· Computeraided design (CAD) involves creating computer models defined by geometrical parameters. These models typically appear on a computer monitor as a threedimensional representation of a part ...

Productivity in the Sawmilling Industries of the United ...

Productivity in the Sawmilling Industries of the United States and Canada: A Nonparametric Analysis ABSTRACT. We use the nonparametric programming approach to estimate technical efficiency and total factor productivity (TFP) growth of sawmill industries in .

Introduction to Milling Tools and Their Application

The most common flute numbers for general milling operations are two (better space for chip ejection) and four (better surface finish). Applications for End Mills Side Milling Face Milling Slot Milling Plunge Milling Ramping Machining of an edge surface on the part. Machining of a top face on the part. Machining between two edge surfaces.

Introduction to Design for Manufacturing Assembly

influence –Basic criteria ... –Quantitative analysis of a design's efficiency –Critique product designs for ease of assembly –The importance of involving production engineers in DFMA analysis . Design for Assembly Definition: DFA is the method of design of the product for ease of assembly.

Improve Wind Turbine Efficiency » Jointiff Limited

Improve Wind Turbine Efficiency by modifying Blade and Vane Blades Numbers, Sizes and Shapes and Pitches. Blades are important components that need to be matched with the wind speed environment in order to maximize the efficiency of a turbine. At low wind speed, more blades will be better and the blades should be long and wide. The blade pitch should be large.

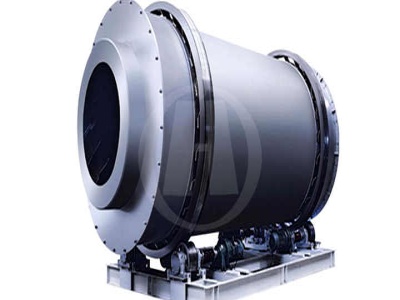

Stirred Milling VERTIMILL® Grinding Mills Stirred Media ...

The stirred milling technologies currently available can be divided into two subcategories: gravityinduced and fluidized. ... to grind efficiency, reduced media consumption, lower installation cost, minimal maintenance, and minimal liner ... because the different parameters have influence on .

CNC Milling Parts

CNC Milling Parts CNC milling parts is the most commonly used machining is the process that removing the material from a workpiece by using rotary milling machines are often classified by the number of axis that they axis for horizontal movement are called X and the axis for vertical movement is called...

12 Ways To Improve Productivity At The Workplace

Oct 07, 2010· Thus the idea is to have devices that enhance efficiency and subsequently productivity at the work place. The devices help to reduce the response time, improve customer service and cutting costs, all imperative for workplace productivity. What are your thoughts? Image: " mug with memo notes / Shutterstock "

NACHIFUJIKOSHI CORP. / Product Info. / Cutting Tools

Application for milling in Aluminum Ultra high speed cutting in DRY! Excellent surface roughness Dry milling is possible by high rake design, and DLC coating on a lapping rake face. Surface roughness of wet milling is realized by dry milling. Applicable end mill X's Mill Wavy 2000 and 3000 models X's Mill Wavy Multifunction types 2000 and 3000

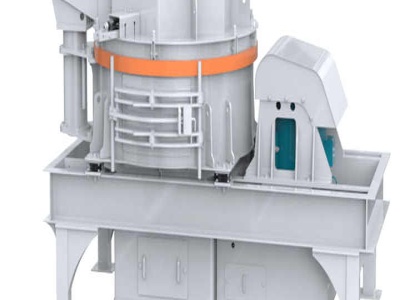

Detail Info AWEA

HOME Vertical Milling BM Series Detail Info Overview Structure Spindle Effeciency i Console Specifications Dealer Network Contact / Inquiry. VERTICAL MILLING PRODUCTION BRIDGE MILLING HIGH SPEED BRIDGE MILLING 5FACE BRIDGE MILLING HORIZONTAL MILLING HORIZONTAL BORING 5AXES MILLING TAPPING AUTOMATION.

LEARNING CNC STRATERGIES AND TIPS: ramp milling

May 28, 2014· Trochoidal machining is a milling process where the tool path continually recrosses itself as the tool feeds through an outline of constant radius arcs as illustrated in Figure 13. This makes use of the advantages of circular milling and slicing so .

The Influence of Battery Bank Sizing on Fuel Cell ...

The Influence of Battery Bank Sizing on Fuel Cell Efficiency in Series Fuel Cell Battery Hybrid Intercity Passenger Railway Vehicles: the case study of the Intercity 125

Latest Posts

- معدات نقل تعدين الفحم

- مصنع طاحونة رمح كرنك

- تأثير طحن لمصنع الأسمنت

- 200 الهيدروكربونات النفطية الفك كسارة الحجر كسارة

- كسارة صخور يدوية صغيرة مصر

- قالب خطة الأعمال كسارة الحجر الحرة

- جداول التعدين الجاذبية للبيع

- إخطار تقييم الأثر البيئي لكسارة الحجر

- الذهب معدات مصنع لتجهيز للبيع

- محمول محطة كسارة المملكة العربية السعودية

- آلة محطم الهاتف إشارة

- سعر المعدات المستعملة في الأرجنتين

- تستخدم كسارة من ألمانيا

- الكرة الصغيرة آلة طحن

- كسارة pp الرافية كسارة مصر

- gold searchinf macines in hydrabad

- copper jaw crusher for sale in malaysia

- magnij crusher machine

- nickel ore ball mill sizes dimensions cost of crusher plant

- apron feeder has vibrant

- coal crusher feed size to

- problems in stone crusher

- magnesium ingot

- bijih besi bola yang digunakan promosi mill

- coal conveyor belts low extraction

- machine for grinding and milling gold in nigeria

- petroleum cokedust collector bags

- grinding equipment au

- gardner denver pr

- molino de martillo para toneladas po hora