grinding on lathe

Grinding Lathe Tools on a Belt Sander ~ Machined Parts ...

Mar 24, 2013· The bench grinder is the most commonly recommended tool for grinding lathe tools. This machine tends to cut slow, cut hot and cut facets. It may work in more experienced hands but for the new guy . maybe not the best tool to learn on.

1932 How to Grind Valves in t WEWilliams index

SOUTH BEND LATHE WORKS if the the side of the valve on The the is lathe as in again to it ru valve n true. 8 satisfactory Manual No, "How to Grind on to truing aNd page 7 for pletc of this Manual. Testing and Straightening Valve Stems in the Lathe All 11 h2d will be the not run e may up. After in the valve 'n Fix. G t Y the in the The valve I or r

Grinding Lathes at Best Price in India

We offer roll grinding lathe machine to our client. These lathe machines combine all the features which is expected in doing heavy jobs with great efficiency and are ideal for all sliding, surfacing and screw cutting operation.

grinding lathe | eBay

710 results for grinding lathe Save grinding lathe to get email alerts and updates on your eBay Feed. Unfollow grinding lathe to stop getting updates on your eBay feed.

MACHINING OPERATIONS AND MACHINE TOOLS

MACHINING OPERATIONS AND MACHINE TOOLS. 1. Turning and Related Operations. 2. Drilling and Related Operations. 3. Milling. 4. Machining Turning Centers. 5. Other Machining Operations ... • Toolroom Lathe and Speed Lathe • Turret Lathe – The tailstock is replaced with a turret • Chucking Machines – No tailstock

Machining Operations Long Beach City College

The lathe is primarily used for cylindrical work. The lathe may be used for: boring, drilling, tapping, turning, facing, threading, polishing, grooving, knurling, trepanning. nonprecision grinding: Nonprecision grinding is a cutting technique used when the grinding does not need to be accurate.

Lathe, Grinding, Milling Screw Machine Centers Suppliers

Centers: Lathe, Grinding, Milling Screw Machine manufacturers, service companies and distributors are listed in this trusted and comprehensive vertical portal. The comprehensive directory provides access to full contact and ability information for sourcing professionals, engineers and researchers wishing to get information on Centers: Lathe, Grinding, Milling Screw Machine.

Sharpening HSS Lathe Tool Bits | Metal Arts Press

Begin by dressing the grinding wheel. Next, look up the typical angles for the workpiece material, and then follow the steps in Figure A–2. Dip the tool in coolant frequently to keep it from overheating and annealing. Any discoloration on the bit indicates it may no longer be hardened. If this happens, consider starting over again from the beginning.

How to sharpen a bowl gouge | Woodturning | Lathe | Turning

Jul 13, 2015· A grinder is used to sharpen a lathe tool. When you sharpen, you remove just a small amount of steel, with the goal of creating a sharp edge. Grinding describes removing a significant amount of metal, usually with the goal of changing the tool's shape. But, before you begin either sharpening or grinding, there is a bit more you must learn.

This is the Taig Catalog The Taig Lathe and Milling Machine

Lathe Dog, holds work piece while turning between centers. A clamp style lathe dog for use in turning between centers Here's an article on turning between centers on the Taig lathe. 1035. Face plate 3 1/4" dia. 3/416 thd mount. The Face Plate is a " diameter steel disc which mounts on the headstock of the lathe.

Lathe Operation Flashcards | Quizlet

Setting up and operating a lathe using various work holding devices Settting up steady and follower rest Drilling,Boring,Knurling,Grinding,and milling operations on a lathe. Industrial applications with a lathe

MILLINGGRINDINGDRILLING AND SLOTTING .

spindle speeds to the grinding wheel size and rating. A wheel guard on the head offers protection to the operator from debris coming off the wheel during grinding. Internal Grinding Attachment A wide variety of internal grinding jobs can be handled on a lathe with the VersaMil basic unit and the internal grinding unit (Figure 93). The ...

Attachments for Lathe Shenoy Engineering

Direct, tool post mounting type, self powered grinding attachment is developed for facilitating quick mounting and dismounting the grinding attachment to the tool post of a lathe, like any other tool holders. Tool Post grinders are commonly available grinding attachments for the lathe.

Grinding (abrasive cutting) Wikipedia

A grinding wheel is an expendable wheel used for various grinding and abrasive machining operations. It is generally made from a matrix of coarse abrasive particles pressed and bonded together to form a solid, circular shape, various profiles and cross sections are available depending on the intended usage for the wheel.

Design, analysis and manufacturing of a grinding ...

Grinding attachment is a special attachment which is purposely made for the lathe to perform a grinding operation on the lathe. For smallsized cylindrical workpieces, it is neither economic nor preferable to use a special type of grinding machine for grinding operations. While in turning or facing process one can obtain surface

Tool Post Grinder, Mini Lathe

Description This tool post grinder is designed specifically for the mini lathe. To install it, you simply replace the compound rest. The bottom of the mounting foot is approximately 50 mm (2") below the centerline of the grinding wheel.

Multi Axis Machining (5 Axis, 9 Axis Simultaneously ...

Our New Mori Seiki NT 5400 SZ is the complete Milling Turning Center. The Capabilities of this machine are nearly endless with 9Axis Simultaneous Machining, 36" of Swing and 70" of Bed.

Woodcentral Turning Forum: Tool Grinds

WoodCentral's Tool Grinds Page. Here are some photos of lathe tool grinds submitted by our Turning forum visitors. It is our suspicion that there are as many grinds as there are turners, and that a skilled turner knows instinctively how to present an edge to the work for the best result.

ONEWAY Manufacturing

ONEWAY Manufacturing, under founder Tim Clay, has set a standard for quality and innovation that is unparalleled in our industry. Our goal is to continue to design, engineer, and develop new products that provide both the hobbyist and professional woodturner the best equipment available anywhere.

Lathe grinding wheel attachment? | WoodBarter

Feb 12, 2017· While I was surfing the internet the other day, I came across a grinding attachment for a lathe. I tried finding the attachment that I saw the other day and I can't seem to locate it now. It was a bit expensive but it got me to thinking, why couldn't someone make and attachment for a grinding wheel for a lathe.

Grinding on a Swiss : Production Machining

Nov 15, 2012· Grinding on a Swiss offers several advantages over milling. Grinding is a continuous cutting process, which can provide a better finish than milling's interrupted cutting process, which induces vibration into the part being machined. Grinding processes operate at a .

Oneway Wolverine Grinding Jig

This is a great and necessary addition to any shop with a wood lathe. The included attachment does a very professional job on gouges and parting tools while the also included "platform jig" allows you to grind bowel scrapers and skew chisels. It does seem a bit pricey but it is a very good quality tool.

Latest Posts

- cara crusher batok kelapa

- سحق مطاحن عملية تجميع

- معدات الحجارة البعد في إيطاليا

- شراء كسارة الصخور المستعملة

- المعطف وسحق جدار الحجر

- التعدين الذهب في مصر المعدات الصغيرة

- مطحنة الفول السوداني من الشركة المصنعة

- سعر كسارة الحديد

- كسارة الدولوميت المحمولة للبيع في اندونيسيا

- حجر محطم السعودية جزيره العرب

- الكسارة jenis jenis الأولية

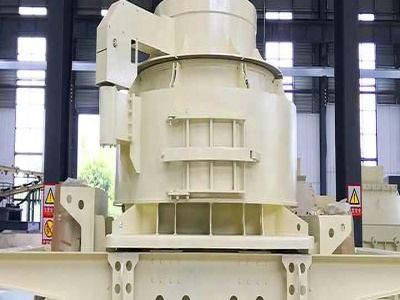

- التصنيع المخروطية الكرة مطحنة

- بيع كسارة الصخور سيمونز

- مطحنة شبه منحرف للبيع السعر

- المصنعين مطحنة الأسمنت في مصر

- i what good stainless steel mill quartz powder

- nick grinder price

- used crushers for sale quipment

- minerals south africa

- what mineral is common to underground mining

- machine names used for coal miningmachine names secondhand for coal mining

- photo fully ppe for grinding welding

- crusher dan grinding mill di nigeria

- hammer mill price in zambia

- typical equipment delivery schedule beneficition plant

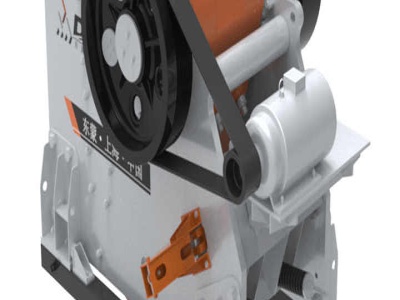

- hard rock crushers manufacturers india mine jaw crusher

- jaw crusher manufacturers mining equipment stone crusher machine

- stone silica sand washing machine

- junkers in to crusher

- manufacturers grinding stone