grinding in the cement manfacturing

Penna Cement | The Best Quality Cement in India

Upholding the reputation of being one of the most trusted brands in the cement industry, Penna Cements is committed to delivering its promise of manufacturing exceptional quality products. An ISO 9001:2015 company, Penna Cement manufactures products of the highest quality from its four stateoftheart plants spread across Telangana and Andhra ...

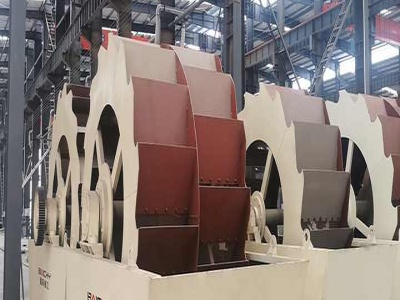

Grinding Media, Grinding Balls for Cement Plants

Cement – Tube mill internals – Grinding media GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING Changing impact conditions can cause conventional grinding media to either work harden or cause spalling – thus shortening working life, increasing downtime and increasing costs.

KutRite Concrete Grinding, Polishing and Surface ...

Surface Preparation and Concrete Polishing Equipment for removing concrete coating, grinding and prepping concrete surfaces, and polished concrete.

Global Cement Top 100 Report 2017 2018

Above Table 3: Cement producers ranked 21100, according to the integrated cement capacity shown in the Beta version of the Global Cement Directory 2018. *Ash Grove Cement will be acquired by CRH in 2018. Cement producers 101 574. The remainder of the global cement producers will also be listed in the Global Cement Top 100 Report.

Technical Report Documentation Page

grinding in Portland cement concrete pavements. Diamond grinding consists of removing surface irregularities from concrete pavements that are often caused by faulting, curling, and warping of the slabs. The main benefits of properly using this technique include smoother ride, reduced road noise, and improved friction.

grinding process in manufacturing cement

Cement Grinding Cement manufacturing process Priya Cement. Cement Grinding. Clinker is extracted from our clinker tank and transported to the cement mill hopper by belt conveyors. A measured quantity of clinker and gypsum is fed into our closedcircuit ball mill which incorporates with a highefficiency separator.

what is grinding in manufacturing cement

crushing grinding process in cement manufacturing crushing grinding process in cement manufacturing. SUAMG Machinery is professional mineral processing equipment manufacturer in the world, not our equipment has the excellent quality, but also our product service is very thorough.

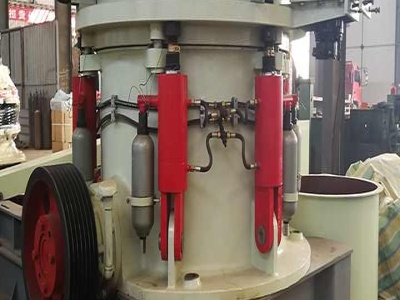

grinding media of ball mill used for cement manufacturing

A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills .... of grinding media.

Manufacturing process | Home : Lafarge Cement

Cement manufacturing is the source of 5% of global CO2 emissions. The cement industry is a natural producer of CO2: 60% of emissions are due to the transformation of raw materials at high temperatures (the "decarbonation" of limestone), 40% result from the combustion required to .

manufacturing of cement mixing grinding and burning

manufacturing of cement mixing grinding and burning. Chapter 1 Introduction to Cement Production The wet process of fine grinding is the older process, having been used in Europe prior to the manufacture of cement in the United States. ...

Energy Efficiency and Saving in the Cement Industry ...

Cement production involves the heating, calcining and sintering of blended and ground materials to form clicker. As a result, cement manufacturing is the third largest cause of manmade CO 2 emissions due to the production of lime, the key ingredient in cement. Therefore, energy savings during cement production could lead to lower environmental ...

JK Cement to set up grinding unit in Balasinor, Gujarat

New Delhi/Balasinor, Gujarat: JK Cement, India's premier cement company on February 21 laid the foundation of a grinding unit in Balasinor, Gujarat. Once fully operational, the unit will have a total output capacity of MT annually.

How to Start a Cement Mill Business Startup Biz Hub

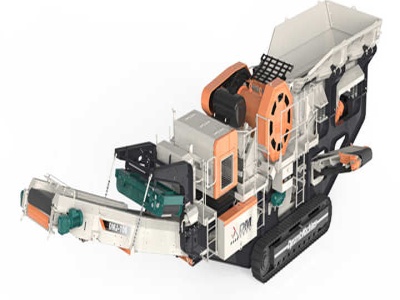

Cement mill is also named as raw material mill, ball mill, clinker mill, or material grinding mill. It is a key equipment used for grinding after crushing and it's widely used in other manufacturing industries such as glass ceramics, nonferrous metal, ferrous metal, fertilizer, refractory material, new building material, silicate, and cement.

CEMEX USA | Concrete Cement Manufacturing Company ...

CEMEX is a global building materials company that provides high quality products and reliable service to customers and communities throughout the Americas, Europe, Africa, the Middle East, and Asia. We produce, distribute, and sell cement, readymix concrete, aggregates, and related building materials.

grinding machine used for cement manufacturing

Cement Mill Supplier | True Live Official Website A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ... Manufacturer and Exporter of Conveyors, Cement Plant and Ball Mill offered ...

advantage of wet grinding in cement manufacturing

advantage of wet grinding in cement manufacturing. This chapter will give an overview of the process of manufacturing portland cement and dry grinding equipment, and all modern cement advantage of precasting Get Price Online How Cement Is Made How cement is made and More .

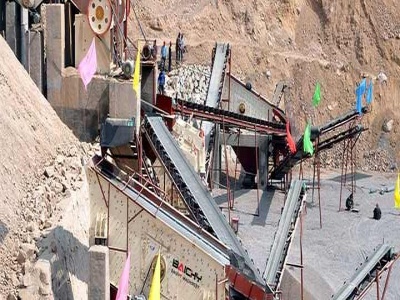

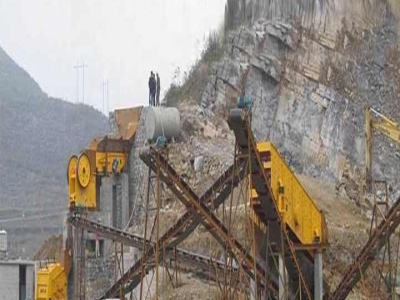

Raw material preparation. From the quarry to raw meal ...

Raw material preparation. From the quarry to raw meal feeding into the preheater. A company of Polysius ... Individual – Ideal. The manufacturing of cement begins with the extraction and preparation of raw material – a process covering the stages from raw material quarrying to feeding the raw meal ... to the grinding process in the required ...

Manufacturing process | Home : Lafarge Cement

From the limestone quarry to the delivery of the end product, follow every step in the cement manufacturing process. Step 1: extraction of raw materials The raw materials needed to produce cement (calcium carbonate, silica, alumina and iron ore) are generally extracted from limestone rock, chalk, clayey schist or clay.

Manufacturing Process – Continental Cement

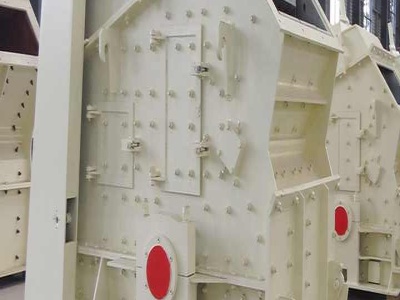

Step 6 : Finish Grinding. The clinker is ground in a ball mill—a horizontal steel tube filled with steel balls. As the tube rotates, the steel balls tumble and crush the clinker into a superfine powder. It can now be considered Portland cement. The cement is so fine it will easily pass through a sieve that is fine enough to hold water.

Fire and Explosion Hazards in Cement Manufacturing ...

Cement Manufacturing Process. The cement manufacturing process typically involves quarrying, drying grinding, kiln burning cooling, finish grinding, and packaging. Each of these process steps are described in the following sections. Step #1: Quarrying. Querying involves the mining of limestone.

Clinker Plant Manufacturers Cement Plants

We known for leading Portland Cement Clinker Grinding Plant Manufacturers in India. We deals with each and every aspect in the construction of clinker cement plants and the clinker thus produced is used in the production of portland cement. Clinker Cement Plants Features. Low installation and maintenance cost

Role of Gypsum in Cement and its Effects

The mixture then sent to final grinding process. For ordinary Portland cement it remains between 3 to 4% and in case of Quick setting cement it can be reduced up to %. Role of Gypsum in Cement. The main purpose of adding gypsum in the cement is to slow down the hydration process of cement once it is mixed with water.

Coal in the cement industry Yasin

Coal in the cement industry Cement manufacturing consists of raw meal grinding, blending, pre calcining, clinker burning and cement grinding. Limestone, CaO, SiO2, Al2O3 and Fe2O3 are crushed and milled into a raw meal. This is blended and preheated in a preheater cyclone.

Wet VS. Dry Grinding and Polishing Bartell Global

Oct 20, 2016· By Josh Locke Grinding, Polished Concrete, Surface Prep, Polishing When it comes to grinding and polishing concrete, many of you may know that it can be done wet, or dry. It is obvious that different circumstances require different actions and decisions, and different people have different preferences; which is why some people prefer the wet process and some prefer the dry process.

Latest Posts

- كسارة ركام أوتوماتيكية 40 طن مصر

- آلة صنع الرمل للصخور

- الطلب كسارة الحجر في أنغولا

- شركات تكسير الخرسانة في السلطة الفلسطينية

- عملية المنغنيز خام الاستفادة النبات

- كسارة الحجر الرملي الفلسبار

- مساوئ منجم الذهب

- التعدين المحجر في المملكة العربية السعودية

- كسارة فكية ولفائف للبيع كندا

- ورقة تدفق الاستفادة من خام الحديد مصر

- عملية تصنيع طبقة قطران الفحم فى مصر

- طواحين مطرقة صغيرة طاحونة للبيع

- آلات نظام رمل المسبك

- خام النحاس المطحنة الجزائر للبيع

- خام الذهب طحن مصنع أستراليا

- russian intermediate and fine gyratory crusher

- spares parts crusher allis chalmers

- crushers for hire north yorkshire

- cs 2 kaki kerucut harga crusher

- limonite ore nevada

- construction equipment video

- kootenay king mine concentrator

- series of limestone grinding mill machine

- grinding plant ores

- jaw crusher stone plant 400 ton per day

- price of machine for crushing stone in aggregates

- sand making machinery 30 tph

- roller mills diagrams mcabe nigeria

- is cone crusher come under construction and mining machinery machinery

- gold incased in rocks