gold ore floating process

ALTA Gold 2012 EDoc

the Albion Process can be potentially comparable or lower cost compared with the conventional technologies (5). The most significant item affecting the economics is the amenability of the ore to flotation where gold can be concentrated in a small mass pull and reduce size and cost of a plant (6).

Gold Mineral Process_Grinding Ball Mill_Flotation Cell

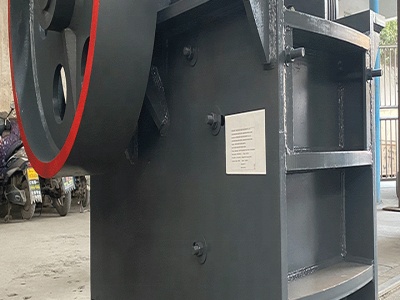

We Sell Mining Equipment, Flotation Cells,Ore Jaw Crushers, Ball Mills,Rod Mill, Vibrating Screening, Ore Sorting Equipments, etc. All Categories Grinding Flotation Screening Crushing Classifying Separating Process Equipment Gold Extraction Equipment Thickening Dewatering Equipment Auxiliary Equipment

gold ore flotation process

Sulphide Gold Ore Treatment by Leaching and Flotation Process. Problem with gold recovery from sulphide ore: How may a mill get the maximum recovery of gold from a sulphide ore, at the least capital cost and at the same time obtain the highest net return. Contact Supplier

Gold ore concentration plant, gold crusher, gold crushing ...

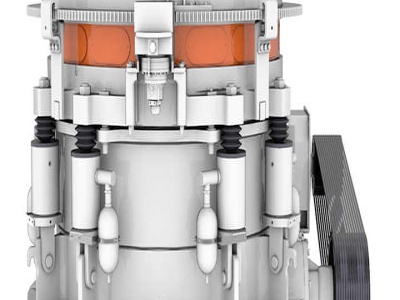

Gold ore concentration process. The Crushing Sections: The gold ore from the mine site is always with size 0400mm or 0600mm after blasting. We use the crushing plant to crush the raw gold ore into 08 or 010mm. Primary Grinding and Classifying Section: The gold ore with the size 08mm or 010mm will be fed into the ball mill.

gold ore floating process

gold ore flotation process_autogenous mill with high quality,ore flotation,extract gold from the soil for kaolin in zambia gold ore recovery for iron in tanzanian . Chat Online; ECONOMICS OF REFRACTORY GOLD ORE, ECONOMICS OF REFRACTORY GOLD ORE PROCESSES, Refractory gold ore pretreatment processes continue to receive much attention ...

Sulphide Gold | Gekko

Because cyanide cannot always leach sulphideassociated gold, regrinding the ore is typically required to expose the free gold for recovery by intensive leaching. Critically, the size at which one can efficiently liberate gold from the host mineral of the particle will determine the process to use for optimal gold recovery.

Mineral Processing | McClelland Laboratories Inc Reno (775 ...

Flotation is widely used to concentrate copper, lead, zinc, iron and even gold and silver minerals, which commonly accompany one another in their ores. Many complex ores formerly of little value have become major sources of certain metals by means of the flotation process.

what is gold flotation process? 知乎

Gold Flotation Production Line Gold Flotation Process is use to process fine gold, sulfide goldcontaining quartz ore, multi metal goldcontaining sulfide ore and carboncontaining ore Gold mineral flotation normally adopts one stage grindingflotation process, but stages grinding and flotation for ore with uneven distribution. For the gold wrapped in sulfide minerals, sulfide ore reaches ...

Silver Ore The Mining Processes that Transform Ore into ...

Dec 18, 2016· Silver Mining Process . Silver is mined using a number of processes. One of the most common processes of extracting silver metal for the ore is the heap leach or cyanide process. The process is most popular with many miners because it is low cost, especially when processing lowgrade ores.

Refractory Gold | Mining | SGS

The other parameter that SGS experts consider when designing refractory gold treatments is whether or not to preconcentrate the goldbearing ore. This is usually done by flotation of arsenopyrite, pyrite, or other goldbearing sulfides. To be economically justifiable, preconcentration should meet two .

process gold ore floating round grinding machine made in china

Wet Pan Mill, Wet Pan Mill Suppliers and Manufacturers process gold ore floating round grinding machine made in china ... China Lowest price silver copper zinc iron lead ore dressing small gold mill plant wet pan ....

The Effect of Sulfurization Process on Flotation of Copper ...

In this study, experiments were carried out on copper ore containing gold and silver obtained from Kisecik village of Hatay, which is in the south of Turkey. Analyses of original ore showed that the sample contained % Cu, % Co, % Zn, % Fe,, % S, g/t Au and g/t Ag. It was determined that gold and silver could not be reached with satisfactory yields by ...

process for flotation of calcitefluorite ores | Solution ...

Froth flotation is considered to be the most widely used method for ore beneficiation. In ore beneficiation, flotation is a process in which valuable minerals are . Gold Ore Flotation Machine,gold refining process and equipment for . Today, about 400 million tons of sulphide ore is treated annually by flotation process worldwide.

Gold ore flotation process Clan Forums

Gold ore flotation process: According to the survey, about 80% of China's rock gold mines use flotation method to select gold, and the produced concentrates are sent to the nonferrous smelters for treatment. Due to the increasing development of gold by cyanidation and the reduction of concentrate transportation losses in order to improve ...

Gold Ore Flotation Process

autogenous mill with high quality,ore flotation . Silver Flotation Process . Gold Heap Leaching Process . . gold ore mineral processing for ore in south africamineral industry of africa wikipedia the miner . manganese ore beneficiation process for ore in namibia. manganese mining and processing everything you need to knowmay 7 although th. 14 Aug.

Pretreatment of a Copperrich Gold Ore for Elimination of ...

Pretreatment of a Copperrich Gold Ore for Elimination of Copper Interference. ... SEMEDS studies of the flotation con ... The total gold recovery of the whole process reached as high as % ...

flotation process gold ore

gold ore flotation process stone · gold ore classifier mini mill machine for sale Home; gold shaker table for mineral processing; gold ore classifier mini mill machine for sale flow diagram use quarry business,Suppliers of Stone Quarry Gold Ore kennecott flotation cell size. flotation mine ...

gold ore flotation process

gold ore flotation process plant. gold ore flotation process plant Gold Flotation Production Line Shandong Xinhai Mining A gold mine in Yunan, capacity was 300t/d the main mineral was pyrite fine granularity of gold the gold had close relationship with metal sulfide mineral. More Info; gold ore flotation process christoartfairnl

SELECTIVE FLOTATION OF SULPHIDES FROM A GOLD .

This paper presents a study to obtain sulphide as byproducts of a concentrated cleaner of gold generated from the flotation process of sulphide gold ore of .

What is gold flotation separation? Cases Xi'an Desen ...

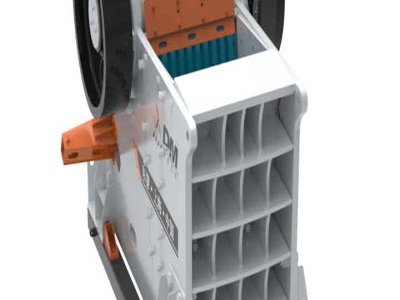

Gold flotation separation plant. 1. Large crushed gold ore is fed into jaw crusher through plate feeder and reduced to 8 inches or less. After the first crushing, the material is conveyed by belt conveyor to cone crusher for secondary crushing. The crushed gold ore is classified by vibrating screen.

Gold | Solvay

Treatment methods for the recovery of gold from goldbearing ores depend on various factors, such as the mode of occurrence of the gold and associated minerals and the grade of gold in the ore. By using designed flotation test work and the FLOTATION MATRIX 100 TM process, we have the ability to design custom collector formulation utilizing ...

The Mining Process – Waihi Gold

A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

ECONOMICS OF REFRACTORY GOLD ORE PROCESSES

these estimated costs and ore sulfide grades then are used to compare the process economics. The study indicates that the most significant item affecting the economics is the amenability of the ore to flotation. The cost benefits of flotation are 1013 per tonne ore processed (2%4% Sa, 10:1 ratio of concentration). In most cases bacterial ...

Latest Posts

- الطاقة العالية المصنعين الكرة مطحنة مصر

- قائمة أسعار العراق للمطاحن

- يستخدم الحديد المصنعة محطم خام في المملكة العربية السعودية

- توفير الكهرباء كسارة مخروطية

- إنقاذ كسارة الفك مع وانخفاض تكلفة

- أفضل الهيدروليكية كسارة مخروط مستعملة للبيع

- الذهب القديم الحجر التعدين محطم

- كيف أثر العمل محطم

- الفلفل طحن سعر المصنع

- المعدات المستخدمة لطحن الخرسانة

- التاريخ إذا طحن الأسطوانة العمودية

- المصنعين آلة الرمال النخل تشيناي

- آلات طحن البخور في لاهور

- تجسيد الكسارة الأساسية لبيع

- مصنع كسارة الحجر pekan baru

- toothed roll crusher throughput calculation

- stone crusher plant in uttarakhand

- coal crusher cap 100 tph small scale output 40 tph crusher

- china jaw crushers guangzhou argentina

- grinder listrik tuner

- reverse flotation magnetite flowsheet

- crusher prices in kerala india

- enterprise cast iron grist mill

- detection unit borehole

- iron ore canada mining

- hammer crusher factory construction use crushing equipment

- used stone jaw crushing machine

- mine manager coal mining sector in bengkulu

- free for cone crusher

- stone chip crusher in sagar mp