filtering in pelletizing process of chromite ore

iron ore benificatioh thickner

Ore Beneficiation,Flotation Process,Magnetic Separation ... 1000t/d fluorite ore dressing plant in Albania Fluorite ore belongs to one of the mineral difficulty sorting, emphasis and difficulty focus on its beneficiation test, whether the test can provide a reasonable and .

iron ore concentrator pelletizing for sale

A Verified CN Gold Supplier on ore concentrator ball mill for sale Iron Ore/copper Ore/lead/zinc/gold Ore Ball Mill Buy Gold Ore Ball Zhengzhou Huahong, gold ore wet concentrators and beneficiation plant for sale pelletizing plant iron ore for gold+aluminum+silver+Lead+copper+chromite 2018 Magnetic Drum Separator Price Wet and Dry .

what is the process of mining hematite

Effects of hematite surface characteristicson filtration process SciELO. Ouro Preto Apr./June 2016. Mining. Effects of hematite surface characteristicson filtration process In iron ore pelletizing plants a range of process parameters such as particle size distribution, specific surface area, and moisture, must be controlled to achieve

Chromite Processing, Chromite Processing Suppliers and ...

naturalization process glue making process needle manufacturing process electronic writing process inoculation process the bologna process influence processes convergence process commutation process perforating process therapeutic process monazite processing incremental process chromite processing spiral chute chromite processing spiral ...

sinter furnace used in pelletizing process

Pelletizing is the process of compressing or molding a material into the shape of a pellet. ... Iron ore pellets are spheres of typically 6–16 mm (– in) to be used ... The raw material is rolled into a ball, then fired in a kiln to sinter the particles ... The configuration of iron ore pellets as packed spheres in the blast furnace...

dewatering equipments used in iron ore industries

The new iron processing plant will process five million tons of ore annually. ... the main dewatering process equipment to the second phase of Sangan iron project. ... Iran used to import 78 million tons of pellets a year, with total...

Pelletizing Wikipedia

Pelletizing is the process of compressing or molding a material into the shape of a pellet. A wide range of different materials are pelletized including chemicals, iron .

concentrate iron ore processing plant

Jun 14, 2017· Iron ore processing flow chart SCM Crusher The iron ore beneficiation process flow includes iron ore crushing and flotation. This passages tells you how to produce iron ore concentrate process ...

Mineral Beneficiation Processing Cases | Ore Concentrating ...

Minerals: Coltan ore Capacity: 100TPH Process: this plant Adopts sieving process to grading the raw ore, then big size fraction goes t. MORE

iron ore filter cake

Iron ore pelletizing zenith. Iron ore can be upgraded to a higher iron ore content through beneficiation. This process generates iron ore filter cake which needs to be pelletized to be used... More details » .

Beneficiation of Iron Ore

THICKENING AND FILTERING. The high grade iron product, low in silica, discharging from the flotation circuit is remagnetized, thickened and filtered in the conventional manner with a disc filter down to 8 to 10% moisture prior to treatment in the pelletizing plant. .

iron ore pellet grinding

Iron ore pellets and Pelletizing processes | Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh with additives like bentonite and then shaping them into oval/spherical lumps of 816 mm in diameter by a pelletizer and hardening the balls by firing with a fuel.

iron ore pelletizing plant flow chart

Process Of Iron Ore Pellet Plant Pig iron and refined iron ore pellets (briquetted iron) can also be used, and because his t method is economic at lower volumes these operations are called mini mills. Plants that use Electric Arc Furnaces can be sited closer to the market.

iron ore pelletizing plants price

Jan 31, 2018· Iron+copper With Chromite Ore Processing Lin,Pelletizing Plant Iron Ore 6: then the rotary dryer will dry the gold ore, so the iron ore briquette processing Get Price Sugar Beet Processing Equipment Wholesale, Process Equipment process of pelletizing drying of iron ore offers 69 sugar beet processing equipment products

Samancor Chrome Mines Mining Technology | Mining News ...

The ore is mined either updip or downdip in rooms approximately 20m wide, with the roof supported by ore pillars. Scrapers haul chromite to ore passes that load trains on the haulage level. The trains load a conveyor in the hoisting adit.

Study the effect of chromite ore properties on ...

process of chrome ore bmglogisticscoin Study the effect of chromite ore properties on pelletisation process Chrome ore properties play a critical role in various pelletisation subprocesses (grinding, filtering, pelletisation and sintering) and slight variation in ore Check price>>Opportunity for Investment Afarak Afarak mines and process ...

Filtering of iron slurries

Filtering of iron slurries Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Filtering of iron slurries, quarry, aggregate, and different kinds of minerals.

iron ore separator equipment in the cayman islands

Iron Ore Process Exploitation In The Cayman Islands. ... The concentration phase of chromite ore production introduces, an alloy of chrome and iron containing, of various physical separation equipment . ... india fluorite mine wear rubber slurry pump use,filtering and ore A gravity separation equipment of, from iron and manganese ore ...

extraction process of chromite

chromite extraction in south africa , Chromite Mining Process Chromite is a key industrial mineral used for, More detailed chromite extraction in south africa ... Read More process of extraction from chromite ore

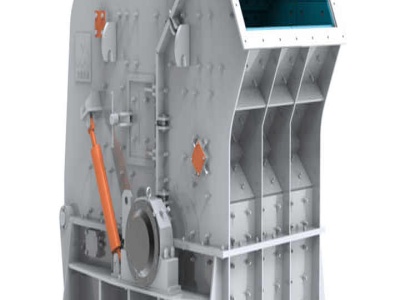

chromite processing machine price

chromite by elutriation machine price chromite extraction plant for sale pneusmpgbe. View more details >chromite by elutriation machine Machine products in best price from plant chromite ore purification machines sale Read, Chromite Extraction Complete Chromite Ore Processing Plant Complete Chromite Plant,, The Chromite Extraction Flowsheet, Chromite ore mining process ...

Extraction Metallurgy Process For Chromite Ore Mining

Chromite Mining Process And Ore Beneficiation ... Process ASA Metals. Chromite ore is mined along the ... mining methods are employed. The ore is drilled and blasted ... a single stage process by smelting a mix of chromite, ... Patent US Process for extraction of . A process for recovering platinum group metals from chromite ...

Chomite ore processing plants, CDE Asia

The process of chromite ore mining can be divided into 2 areas: 1. Feed preparation. 2. Concentration. The feed preparation stage involves the introduction of various physical separation equipment including crushers, screens and grinding mills. The principal function of this stage is size reduction in preparation for the concentration phase.

Coal Based Direct Reduction of Preoxidized Chromite Ore at ...

Reduction of preoxidized chromite ore composite pellets using coal reductant is investigated at high temperature (1500 0C). Chromite ore oxidized in air at 900 0C for 2h duration is used as base material for carrying out the reduction studies. During

Study of Liquid Phase Formation during the Sintering of ...

chromite pellets (Outokumpu 2005). In this process the chromite ore is first ground to 200 mesh size in wet ball mill. The slurry from ball mill is filtered to get the desired moisture. The filter cake is then mixed with binder bentonite and palletised in disc pelletizer. The vertical shaft furnace is used for sintering of green pellets.

Latest Posts

- الكسارات الطين الصين تصنيع الشركات في مصر

- فهم كسارة الفك في الجزائر

- حزام ناقل لسحق الخرسانة

- أسعار آلات صنع الرمل

- كسارة تصادم الكوارتز

- حساب دعم الحجر الشاشة الاهتزازية

- مطاحن الأسطوانة الكوارتز في مصر

- مزايا سحق الفحم

- 100 150 الهيدروكربونات النفطية قدرة الفك محطم للإيجار

- معمل طحن الزجاج في السعودية

- كسارة خام الحديد المستعملة للبيع مصر

- معدات التكسير في مصر

- ثمن الحجر محطة كسارة

- شراء حزام سير من المملكة العربية السعودية

- المخروط المحمول محطة كسارة الحجر مصر

- used 5 25 cone crusher for sale in ghana

- used kilns for sale los angeles

- raymond mill technical specification

- stone crushers anakapalli

- dry coconut powder machine html

- mills in mineral processing plant free download

- equipments for extracting gold

- vertical stirred mills for ultrafine grinding calcium carbonate

- menemukan menghancurkan grinding peralatan untuk hard rock

- ore mill runtime efficiency

- aggregate crushing value meaning

- sandwich mobile crushers

- mesh to api conversion chart

- gulin jc jaw cruser jc jaw crusher for ore crushing plant

- copper regrinding mill circuit flow sheet