e tractive titanium metallurgy ppt

Heat Treatment

Department of Materials Science and Metallurgy University of Cambridge ... growth. Heat treatment of aluminum, copper, magnesium, titanium and nickel alloys. Temper designations for aluminum and magnesium alloys. Controlled Atmospheres Oxidizing, reducing and neutral atmospheres. 3. Suggested Reading R. E. ReedHill and R. Abbaschian ...

Ellingham diagram Wikipedia

In metallurgy, the Ellingham diagram is used to predict the equilibrium temperature between a metal, its oxide, and oxygen — and by extension, reactions of a metal with sulfur, nitrogen, and other nonmetals. The diagrams are useful in predicting the conditions under which an ore will be reduced to .

Titanium its Alloys Harry Bhadeshia

Materials Science Metallurgy Part II Course C9, Alloys, H. K. D. H. Bhadeshia Titanium its Alloys Pure Titanium Pure titanium melts at 1670 C and has a density of gcm−3. It should therefore be ideal for use in components which operate at el

How to weld dissimilar materials American Welding Society

Jun 20, 2013· Dear All, I am now studying how to weld dissimilar metals and it make me very headache. Could someone of you help me to answer below questions? 1. The metallurgy of weld while welding dissimilar metals? 2. When we weld dissimilar metals, what aspect we .

VŠB TECHNICAL UNIVERSITY OF OSTRAVA FACULTY .

THEORY OF PRODUCTION OF NONFERROUS METALS AND ALLOYS Study Support Kateřina Skotnicová, Monika Losertová, Miroslav Kursa Ostrava 2015 VŠB TECHNICAL UNIVERSITY OF OSTRAVA FACULTY OF METALLURGY AND MATERIALS ENGINEERING

PowerPoint 프레젠테이션 PKNU

and, in selected instances, tungsten, titanium, rhenium, and other highmeltingpoint materials. Physicalmechanical production methods These methods of a manufacture of powder metals and alloys include above all or ... Fundamentals of powder Metallurgy . Water drop Metal stream ... (E). Some of these droplets freeze immediately into small ...

Dissimilar Materials Weldability Concepts

3 December 15, 2015 Dissimilar Materials Weldability Concepts Dr. Alber Sadek Technology Lead – Materials Engineering EWI asadek

A literature review of titanium metallurgical processes ...

A literature review of titanium metallurgical processes ... K. DringA review of advances in processing and metallurgy of titanium alloys. Mater. Sci. Technol., 22 (8) (2006), pp. 881887 ... V. I., Sridhar, R., Rishea, M. M., and Joseph, D. E. Laat R, 2001. Production of titanium metal from titaniumbearing ores involves leaching and selective ...

Cutting Tool: Meaning, Types and Angles | Metal Working

ADVERTISEMENTS: After reading this article you will learn about: 1. Meaning of Cutting Tool 2. Types of Cutting Tools 3. Angles 4. Signature. Meaning of Cutting Tool: A cutting tool in metal working can be defined as "any tool that is used to remove metal from the work piece by .

Titanium Technologies Workshop DMTC

activity of titanium activities in Australia, grouped by subject matter ( machining technologies, additive manufacturing technologies, etc.) rather than an attempt to rank capabilities of individual researchers, research groups or organisations. Attendance at the workshop was open to any researcher or research organisation representative in

additive Manufacturing material Ti6Al4V. selective ...

• Grade 2 Titanium • Ti6Al4V • CoCr 1 Steering column mount for Formula Student race car, ... ( density, microstructure, impurities, mechanical ... in powder metallurgy, Fraunhofer IFAM Dresden is a strong and reliable RD partner in these fields.

A reviewofcopperhydrometallurgy SAIMM

metallurgy sincethat achieved by Sherritt Gordon intheir successful development of pressureleaching techniques. (c)Many ofthe basic chemicals required for hydrometallurgical processes are produced in large tonnages at low prices (, oxygen, ammonia, chlorine, hydrochloric acid). Of course, if your process requires sulphuric

Joining of Metals: Top 5 Methods used to Join Metals

ADVERTISEMENTS: This article throws light upon the top five methods used for joining of metals. The methods are: 1. Soldering 2. Brazing 3. Brazing Flux 4. Riveting 5. Welding. Joining of Metals: Method # 1. Soldering: There are various common methods of joining parts together used in Engineering works. Soldering is one of the techniques [.]

Nickel(2).doc | Nickel | Alloy

Toxicity B'posure to nickel metal and soluble compounds should not e'ceed !.! mgFcmI in nickel e

Titanium An introduction to the element, its alloys, and ...

Aug 29, 2018· ASM International, 2000. Probably the best detailed reference about titanium currently available. Covers titanium metal and its alloys, processing methods, and future trends. Titanium by Gerd Lütjering and James Case Williams. Springer, 2003. A more uptodate reference covering all aspects of titanium metallurgy, extraction, and processing.

beneficiation of titanium ore doc

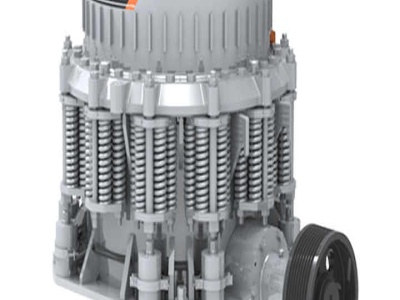

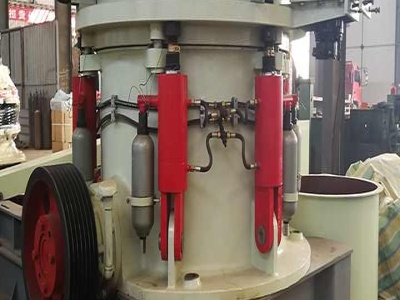

crusher used in iron ore processing doc. 19/9/2018 · Titanium Beneficiation Process % Crusher USA titanium ore beneficiation process somalia beneficiation of titanium ore doc Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction This Contact Us The Six Main ...

Failure Modes in Hybrid Titanium Composite Laminates ...

Jan 27, 2017· Hybrid titanium composite laminates (HTCLs) combine the benefits of thin titanium sheets and fiberreinforced polymer (FRP) composite laminates to design high performance lightweight materials with optimized impact resistance, fracture toughness, durability, and/or thermal performance.

Metallurgy Material Engineering: Forms of corrosion

Use low carbon ( 304L, 316L) grade of stainless steels ; Use stabilized grades alloyed with titanium (for example type 321) or niobium (for example type 347). Titanium and niobium are strong carbide formers. They react with the carbon to .

High Entropy Alloys Chalmers Publication Library (CPL)

High Entropy Alloys: Breakthrough Materials for Aero Engine Applications? DANIEL O. SVENSSON Department of Materials and Manufacturing Technology Chalmers University of Technology SUMMARY In this project the current literature regarding a relatively new materials type, highentropy alloys .

International Titanium Association

The International Titanium Association (ITA) is a membership based international trade association dedicated to the titanium metal industry. Established in 1984, the ITA's main mission is to connect the public interested in using titanium with specialists from across the globe who may offer sales and technical assistance.

Heat Treatment of Cast Irons | | Industrial Heating

Dec 12, 2018· Highalloy (, high chromium, high nickelchromium) white irons can be heat treated. For example, nickelchromium whiteiron castings are given a stressrelief heat treatment because, properly made, they have an ascast martensitic matrix structure. Tempering is performed between 205°C (400°F) and 260°C (450°F) for at least 4 hours.

Latest Posts

- اسعار مطاحن الكرة المصرية

- عقد صيانة محطة كسارة الحجر في مصر

- الفك محطم مصغرة يستخدم سعر

- الحجر محطم 120 الهيدروكربونات النفطية في قدرة ساعة

- استخراج الرمال وحصادها في العراق

- كسارات وفرز مستعملة للبيع في العراق

- مصنع معالجة الذهب في آلة كسارة الحجر العراقي

- استخدام كسارة الحجر كسارة الفك تتحرك

- الفك سحق مصنع للبيع

- معدات مطحنة ريمون للبيع بكرات

- كسارة فكية للبيع من المملكة العربية السعودية

- سحقت الشركات المصنعة للحجر في الفصل

- مطحنة الفحم الدوارة الأفقية للشعلات

- صخرة محطم في الجزائر

- مقدمة من الآلات المعادن

- seller of crusher contact

- beijing dscd technology and services co ltd

- factory of stone crush

- belt conveyor design book

- mp j crawler type mobile jaw crusher

- road milling machine for hire south africa

- stone crushing equipment suppliers india

- price crusher jaws pdf 200x300

- pulverizer milling plant popular germany

- standard stone crusher layoutpdf

- metallurgical centrifugal concentrator

- old concrete crusher for sale india

- ballast sizes for railway track

- nanchong gravel processing equipment

- glenridge quarry naturalization site