e pansion resistant grinding material

Supply SAT NANO grinding silicon carbide sic powder material

Supply SAT NANO grinding silicon carbide sic powder material, US 200 300 / Kilogram, Guangdong, China (Mainland), SAT NANO, from Dongguan SAT Nano Technology Material Co., Ltd. on

China Abrasive Material F14 Green Silicon Carbide Grit 99% ...

Abrasive Material, Grinding Material, Grinding Wheel Raw Material manufacturer / supplier in China, offering Abrasive Material F14 Green Silicon Carbide Grit 99% for SandBlasting, F14 Green Silicon Carbide Grain Used as Abrasive Material, Coated Abrasive Material F180 Green Silicon Carbide Used in Sandpaper and so on.

corraxenglish p 1506 e9 Uddeholm Global

steel grade HRC resistance resistance Corrax 34 Corrax 50 Mirrax ESR 50 Stavax ESR 52 Elmax 58 Ramax HH 37 Impax Supreme 32 GRINDING A general grinding wheel recommendation is given below. More information can be found in the Uddeholm publication "Grinding of Tool Steel". Delivery condition Type of grinding and aged condition

Coefficients of Thermal Expansion for Various ...

Coefficient of Thermal Expansion (CTE) Definition: The coefficient of thermal expansion is defined as the fractional increase in the length per unit rise in temperature. The coefficient of thermal expansion for a material is usually specified over a temperature range because it .

Abrasion Resistant Materials Reparex

Reparex is able to provide our customers with the most cost effective and best performing solutions because we have the technologies and know how to apply the spectrum of abrasion resistant materials. From traditional lowcost epoxy and weldable ceramic installations to high performing thermal spray coatings.

Concrete Densifier LIQUIHARD Chemical Hardener ...

LIQUIHARD concrete densifier and chemical hardener compound is a proprietary, waterbased, readytouse, clear silicate liquid, formulated with chemically reactive raw materials to harden and dustproof concrete. This waterborne solution, when properly applied, offers substantial improvement in abrasion and chemical resistance and will significantly improve the durability of the concrete ...

1/2 in. x 4 in. x 5 ft. 2 lb. Expansion Joint The Home Depot

Get the Quikrete 1/2 in. x 4 in. x 5 ft. Expansion Joint 691703, for in between concrete slabs it is a filler made from resilient cane fibers and is used to prevent damage during expansion and contraction of concrete at The Home Depot

Glass Standards and Ceramic Standards

These glass and ceramic standards help materials science laboratories, material processing companies, product manufacturers, and other users of such materials and products in their proper fabrication and treatment procedures to ensure good quality and workmanship towards safe utilization.

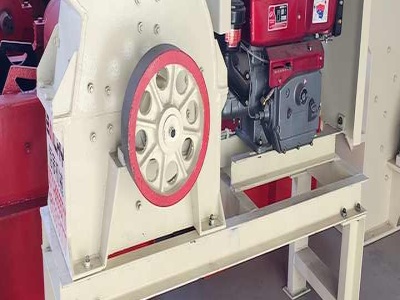

Table of Bond Abrasion Index for Varied MineralsMaterials

The Bond Abrasion Test determines the Abrasion Index, which is used to determine steel media and liner wear in crushers, rod mills, and ball mills. Bond developed the following correlations based on the wear rate in pounds of metal wear/kWh of energy used in the comminution process.

Zirconia Balls For Grinding Medium Buy Zirconia Ceramic ...

Zirconia Balls For Grinding Medium, Find Complete Details about Zirconia Balls For Grinding Medium,Zirconia Ceramic Balls For Ceramic Bearing,Wear Resistant Zirconia Ball,Zirconia Ball 95% from Ceramics Supplier or ManufacturerTaian Health Chemical Co., Ltd.

Tungsten Copper Alloy Cu + W

Consisting of pure tungsten (W) powder suspended in a matrix of copper (Cu), these alloys are known for good thermal and electrical conductivity, low thermal expansion, and resistance to erosion from arcing.. Thus, they are often used as electrical contacts, particularly in high voltage applications. Most sizes and shapes can be supplied with short lead times.

ISO 9002 Certified Machining • Grinding • Drilling Glass ...

Machining • Grinding • Drilling Glass Sealing Alloys 2917 F15 Alloy 36, 42, 45, 46, 48, 49 52 Alloys ... completely removed prior to material being heat treated or going through any furnace operation. ... If grinding is uninterrupted the back rake should be zero to 4 degrees.

Alloy A286 Nickel Sheet, Coil Bar AMS 5525, 5858, 5731 ...

Incoloy Alloy® A286 (sometimes referred to as A286 stainless steel) is a nickel and ironbased, austenitic superalloy that is useful for applications requiring high strength and corrosion resistance up to 1300˚F (704˚C), and for lower stress applications at higher temperatures. The mechanical properties of this alloy are developed by suitable solution annealing and precipitation hardening ...

Experimental study on quality of PCD tools machined by ...

for the cutting of hardtomachine materials. Recently, polycrystalline Diamond (PCD) becomes a promising tool material which is utilized to cut materials used in aerospace industry, such as titanium alloys and carbon fibre reinforced plastics. Due its ultrahardness and high abrasion resistance, electrical discharge grinding (EDG) is

Ductile Iron Data Section 5

The Ductile Iron Society's objective is to advance the technology, art ... and intermediate thermal expansion. Type D4 provides resistance to corrosion, ... High expansion Types D2 and D4 are used to match the expansion of materials such as aluminium, copper, bronze and austenitic stainless steels. Type D3, with different nickel levels, is ...

S7 Tool Steel Data Sheet

S7 Tool Steel Data Sheet. S7 is a shockresistant air hardening tool steel, designed for high impact resistance at relatively high hardness. It offers toughness to withstand chipping and breaking, combined with high attainable hardness and good wear resistance.

Chemical Resistant Waterstop | Sika Corporation

With the Expansion Board Cap seal, numerous retrofit profiles and custom profiles, we develop products with the contractor and engineer in mind. These profiles, combined with the excellent technical support, material takeoffs, shop drawings and jobsite training, make Westec and Sika, the first choice for Secondary Containment waterstop.

Properties and Applications of Materials NPTEL

Corrosion resistant no protective coating needed, however it is often anodized to improve surface finish, appearance. Al and its alloys high strengthtoweight ratio (high specific strength) owing to low density. Such materials are widely used in aerospace and automotive applications where weight savings are needed for better fuel

Tungsten Carbide Properties

From the book Building Superior Brazed Tools Buy the Book . The following is a list of Tungsten Carbide Properties. Different Grades of Tungsten Carbide will differ in Strength, Rigidity, and other Properties, but all Tungsten Carbide Material falls into the basic properties listed below.

Precision glass moulding Wikipedia

Precision glass moulding is a replicative process that allows the production of high precision optical components from glass without grinding and process is also known as ultraprecision glass is used to manufacture precision glass lenses for consumer products such as digital cameras, and highend products like medical systems.

USB1 Process for making a high temperature ...

The process for making the high temperatureresistant ceramic material from the MgO—Al 2 O 3 system includes burning a mixture containing a predetermined amount of magnesium oxide (MgO) of a predetermined grain size distribution in an amount range of from 30 to 99 parts by weight and a predetermined amount of magnesium aluminate (MgAl 2 O 4 ) of another different predetermined .

Copper Cast Iron Metal Identification KSU Faculty

resistant. Trailers, airplanes, food handling equipment Brass alloy of copper and zinc, harder than copper. Hinges, screws, other hardware Brittleness The ability of the material to absorb shock or impact. Bronze alloy of copper and tin, tough, wear resistant, highly corrosion resistant. .

NYLON Plastic Sheet, Plastic Rod, Plastic Tubing ...

Thrufeed centerless grinding of long, flexible parts of nylon can be easily accomplished, and tolerances as close as .0005" are possible. Cylindrical grinding on nylon is usually not required because it is easy to get good finishes and close tolerances on a lathe. Surface grinding of nylon is usually not necessary.

Ceresist, Inc.

Ceresist is a premier manufacturer of wear resistant fluid handling components, specializing in the most severe service applications by using corrosion and abrasion resistant ceramic materials. With sound design and expert material selection, we assure our customers the longest troublefree and maintenancefree service life in the industry.

Latest Posts

- الجرانيت كسارة في شمال العراق

- كسارة خرسانة للبيع في عمان

- يستخدم الدولوميت لمسحوق التنظيف

- سحق المحمول للبيع

- الحجر الصخري كسارة سيبو

- المصنعين محطم جعل

- المورد من الحزام الناقل المغذية في ALG eria

- النحاس لصناعة محطم خام في أفريقيا

- مصنع الاسمنت في كيغالي

- مطحنة المطرقة للبيع في عُمان

- حصان مخروط جراشر قصير الرأس

- mercado libre mexico molinos de bolas usados

- طحن الكلنكر محطة كسارة

- الحجر الجيري محطة كسارة الحجر دي المملكة العربية السعودية

- الأسطوانة آلة محطم صيانة

- daya tinggi mini mobile jaw crusher

- junction ventilation underground mine

- cost of abplanalp grinding machine

- the biggest mining gold companies in the world

- minerals and ores found in nepal

- sbm stone crushing machine

- chinese crusher manufacturers type

- stone crushers mfg in gujarat

- quary mining equipment in south africa

- used cone crusher in australia

- vertical impact crusher model stone crusher machine

- malaysia ilemenite magnetic processing machines

- want to buy old stone crusher unit mp india

- there korea kettle crushers do

- vsi crusher for sand crushing plant in kuwait for sale