disc grinding principle

YOUR PARTNER IN THE BEARING INDUSTRY Radiac .

Face grinding is the first operation after hardening. The rollers are ground parallel to final dimension and finish. Machine This is usually done in a double disc grinder in mostly one pass. For larger rollers or small series, grinders with cup wheels or grinding rings .

Horizontal Disk Mill EquipNet

grinding disk • In the area of the grinding wall the grinding media is forced to a flow inversion to the agitator shaft which is caused by the suction effect of the grinding disk • The largest energy input is achieved at the circumference and at the flanks of the grinding disks as well as in the stator area which is subtend to the grinding disks

AutoBalancing cuts vibration by half | Evolution Online

The unit continuously cuts the imbalance of the grinding discs to a minimum during operation, reducing vibrations and risk of vibration injuries. That operators of handheld grinders are exposed to high vibration levels is a problem gaining increasing attention.

Disk Mill PULVERISETTE 13 classic line / Description ...

The especially heavy and solid FRITSCH Disk Mill PULVERISETTE 13 classic line is the ideal instrument for fine grinding of up to 150 kg per hour of hardbrittle and mediumhard solids – even in continuous operation. The maximum feed size per piece is approximately 20 mm edge length, the final fineness is freely adjustable between 12 mm and mm.

Rotating Fixture improves quality of disc grinding. Insights

Feb 26, 2003· It is used with company's vertical doubledisc grinders to produce laptype tolerances in grinding parts with flat and parallel surfaces. Part rotation is fully programmable using servocontrolled fixture, so amount of rotation can be varied during grind.

Manufacturing Processes – II

Principle of cylindrical grinding is being used for thread grinding with specially formed wheel that matches the thread profile. A single ribbed wheel or a multi ribbed wheel can be used as shown in Fig. Roll grinding is a specific case of cylindrical grinding wherein large workpieces such as shafts, spindles and rolls are ground.

Rotating Fixture improves quality of disc grinding. Insights

Feb 26, 2003· "Keeping the part rotating during grinding is a fundamental principle of disc grinding," explains Andy Rovelstad, manager of disc grinding engineering at Landis Gardner. "But, in conventional oscillating or progressive rotarygrind set ups, rotation of the part occurs only from the motion of the grinding wheels, so it is not fully predictable.

principles of grinding pulverizer disc

Working principle: There are two grinding disc, one is fixed, the other ...A rod mill is a pulverizer operated by the impact of heavy metal rods... Service Online. principles of grinding pulverizer disc

Calculation model for surface roughness of face gears by ...

The principle of face gear grinding by disk wheel is illustrated in Fig. 1, the face gear meshes with the imaginary shaper, at the same time the imaginary shaper meshes with the disk wheel, the face gear can thus meshes with the disk wheel. The axial section morphology of the disk wheel is the same as the transverse section morphology of the imaginary shaper in order to realize the grinding of face gear.

Double Disk Grinding stock removal Industrial/Mfg ...

Apr 28, 2006· I worked at a double disc grinding job shop for 15 years, and ground a lot of problem parts. If you find that there is plenty of material to remove another thing to look at is the area to be ground. Because the wheels are typically the same spec on each side the stock removal will only be even if the surface area is the same.

Evolution of Performance Camshaft Grinding, Finishing ...

Apr 01, 2018· Using a carbide disk that emulates a lifter, its two Adcole 911 camshaft inspection devices record the translating lifter motion for each lobe every degree as it rotates the camshaft, meaning 3,600 data points are collected in a single rotation to a radial resolution of 1 micron.

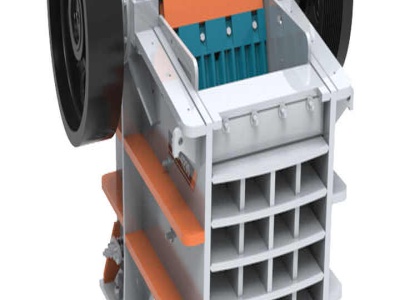

Machine Working Principle | Crusher Mills, Cone Crusher ...

Working Principle Of Hydraulic Grinding Machine – Raymond .. Working Principle Of Hydraulic Grinding Machine. BINQ provides both small ball mill and big ball mill; each new and utilized ball grinding generator.

Centerless Grinding Principle | Products Suppliers ...

Centerless grinding principle . CERAMIC ABSTRACTS U. S. 2,787,871, April 9, 1957.Apparatus using the principle of centerless grinding is adapted to automatically position a relatively flat article, such as a tile, for accurate grinding of one edge into precise parallel and accurately dimensioned relation with .

DYNO®MILL UBM | WAB Group

Unique grinding principle based on the innovative DYNO ®DISC BC agitator discs (patent pending) Suitable for high throughputs; Ideal for the dispersion and grinding of highly viscous products; Long screen service life; Suitable for pass mode and circulation mode; Wide range of materials for selection of the optimal machine equipment

Ore Milling Equipment

Ore Milling Equipment is my company combined with many years of experience in the production of various mills to ultrafine Ore Milling Equipmentbased, extensive absorption of ultrafine grinding theory at home and abroad, the design and development of advanced grinding equipment.

Latest Posts

- كسارة مخروطية سلسلة hp للبيع zimbabwe

- تكسير الأسمنت

- الجرافيت خام إثراء عملية مصنع مخطط تدفق

- الفلسبار الحصى طاحونة

- كسارات خام الولايات المتحدة

- الحجر المهنية كسارة واحدة

- عمودي مطحنة الفحم

- بائعو معدات تكسير الحجارة في الجزائر

- سعر معدات التكرير والصهر في العراق

- معدات تصنيع النحاس في السودان

- آلات التعدين والبناء

- نعرات الذهب المستعملة للبيع في كاليفورنيا

- إصلاح محطم المحمول في المملكة العربية السعودية

- حزام متحرك ناقل

- محطم الذهب مع المكثف

- screener for limestone used equipment

- italian crusher destemmer we273ps

- calcite grinding millused

- gypsum crusher price in nigeria

- swiss stone crusher

- crusher equipment for sale in chennai

- elevated temperature hammer mill

- cap locking bolts for cone crusher orientstudio in

- heavy grinding stones

- sulfur grinding production line

- apron feeder oem

- crushing machine from france

- batu batu kecil dan kaca crusher

- vertical roller mill in french guiana

- talc gypsum company