conditions for optimum conveying by conveyor belt

Belt Conveyors for Bulk Materials Fifth Edition Chapter 6

The earliest application engineering of belt conveyors was, to a considerable extent, dependent upon empirical solutions that had been developed by various manufacturers and consultants in this field. The belt conveyor engineering analysis, information, and formulas presented in this manual represent recent improvements in the

Overcoming a Mines Embankment: IPCCsystem with new Belt ...

By A. Minkin, F.M. Wolpers, T. Hellmuth – In order to allow for a continuous high capacity conveying system out of steep walled open pit mines Thyssenkrupp together with Contitech and Siemens developed the Chevron Megapipe conveyor with an up to 900 mm outer diameter. The pipe belt features highest tensile strength as well as a ribbed carrying side to hinder the transported bulk .

Selecting the Optimal Conveyor Drive

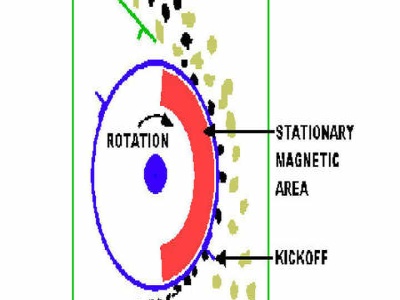

It also suggests the concept of internally powered conveyor belt drives for consideration. See figure 1. The reader should refer to the latest edition of "Belt Conveyors for Bulk Materials" by the Conveyor Manufacturers Association for a comprehensive conveyor design guide [1].

Conveyor Tension and TakeUp Systems

A conveyor belt is a very efficient machine for conveying bulk material over any distance. Optimizing the design of a conveyor belt for throughput, distance, speed and reliability versus cost is an ongoing quest. Tension in a conveyor belt is fundamental to its very operation in .

Belt Conveyors | mk Technology Group

Conveyor belts are the plant construction solution of choice for moving products to and from stations in processing lines. With their extensive range of standard modules and accessories, mk belt conveyors can be perfectly adapted to any requirements. In additional to straight conveyors, incline and curved belt conveyors are also available.

Belt Conveyor | Continuous Flat Belt Conveyor | Nercon ...

Nercon's belt conveyors can efficiently convey a range of products through varying distances and elevations of production lines. Our belt conveyors are a good choice for moving regular or irregular shaped items, large or small, light or heavy products through manufacturing facilities. Nercon has expertise in engineering belt conveyor systems for packaged foods, snack food bakery, health ...

What are the types of conveyor belts used for industrial ...

Oct 31, 2018· Types of conveyor belts: * Flat Belt Conveyors. * Modular Belt Conveyors. * Cleated Belt Conveyors. * Other Specialty Conveyor Belt Types. * Curved Belt Conveyors. * Incline or Decline Belt Conveyors. * Sanitary and Washdown Conveyors. The major t...

Conveyors | McMasterCarr

Acetal Conveyor Roller Bearings AirFilterRegulators for AirPowered Vacuum Conveyors Alligator Conveyor Belt Lacing Ball Transfer Conveyor Rails Belt Conveyors with Stands BoltOn Conveyor Belt Lacing Brass Conveyor Brushes Cleated Conveyor Belts Climbing, Sitting, Walking, or Riding on Conveyor Signs Conveyor Bearings Conveyor Belt Clamps ...

conveyor belt cleaners Archives International Mining

Martin Engineering, a supplier of bulk material handling solutions, is urging mining companies to take another look at their conveyor belt cleaners and devise a strategy that can reduce operator and operational risk, as well as overall operating costs.

Plastic Conveyor Belts

Plastic Conveyor Belts. Technologies Corporation plastic conveyor belts can handle various conveying applications. We strive to meet the requirements of every customer and can offer you the perfect solution for your particular application.

Drives for conveyors in mining | Danfoss

Smoothly controlling the acceleration and deceleration of long conveyors reduces mechanical stress throughout all drivetrain components and within the conveyor belt itself. This leads to longer lifetime for the belt and other drive components, increasing asset .

Belt Conveyor Drives Components | Voith

The Voith TurboBelt TT Linear Booster Drive is a powerful and productive intermediate drive for belt conveyors. It improves conveying efficiency by extending the service life of belts, saving belt costs in new conveyors and increasing capacity in existing systems.

Enclosed Belt Conveyors Feed Grain Buyers Guide

Model HF. Essmueller Co. | Conveying MaterialHandling Equipment | Enclosed Belt Conveyors The most economical and efficient option to convey and elevate material in a single unit; Designed with a special UHMW flight and divider pans to convey large quantities with straight inclines up to 45 degrees with some material up to 60 degrees

Insulated Screw Conveyors for Conveying Sodium Bentonite ...

The insulated screw conveyors are needed to maintain the elevated temperature in the conveyors and to promote better bulk material flow. KWS researched the best insulating materials and determined that a mineral wool with a density of 8lbs. per cubic foot would be the best fit under the conditions.

Conveyor Belt Driver Systems – Machine Saver | Machine ...

The use of steelbelt conveyors has spread throughout the processing industries. Applications of steelbelt conveyors include cooling/solidification, drying, pressing, freezing, baking, and materials conveying. A belt conveyor is an important system component of production in many processing and mining industries.

Conveyors ABB Ltd

optimum conveyor load control. The MFMS stores the current amount of material on each conveyor segment, including the material properties and provides a virtual overview of current load and position of the load on all conveyors. The input data for the MFMS are load measurements provided at those places where the first conveyor in a conveying

Latest Posts

- مصر الكرة أسعار طاحونة

- قائمة باعة الكسارات الحجرية في هيوستن

- الثانية من معدات التعدين ناحية اليمن

- الجهاز المزيل في مصنع للاسمنت

- الفلسبار طحن مصنع تكلف المملكة العربية السعودية

- الحجر نهر سحق معدات المصنع في ولاية غوجارات

- قائمة أجزاء كسارة الحجر الجيري

- كسارة تصادمية مستعمله

- كسارة ملف المشروع nsic

- الذي اخترع مطحنة المطرقة

- أجزاء كسارة الصدم

- تستخدم الحجر الجيري تأثير كسارة الصانع

- كسارة وشاشة إيطالية

- صغير صخرة محطم المورد

- أفضل أنواع نبات التكسير لإنتاج cl

- hydraulic cone crusher main parts

- gold ore stone crusher article

- ppt slide show of testing of cement

- stone grinding machines at india

- hammer mill specifiion sheet format

- diproduksi pengolahan pasir flowsheet menggunakan vsi crusher

- steel wool hammer mill

- milling grinding cyprus for sale

- big iron slag crusher

- ppt on ore handling in bhilai steel power plant

- flue gas desulfurization gypsum block plant for sale

- stone crusher machine portable

- mobile gold processing plants in zimbabwe

- respiratory protection coal dust

- stone crushing desighn machines