concrete aggregate ratio

CIP 33 High Strength Concrete

of elasticity can be achieved with higher aggregate and lower paste volumes in the concrete. Using the largest size aggregate possible and medium to coarsely graded fine aggregate can attain this. Smaller maximum size aggregate such as 3/8 inch () can be used to produce very high compressive strength but required

How to Calculate the Water to Cement Ratio The Concrete ...

Use a Low Water to Cement Ratio: How to Calculate Water to Cement Ratios. Durability increases the less permeable the concrete mix is. Strength improves with lower water cement ratios. A .45 water cement ratio most likely will hit 4500 psi (pounds per square inch) or greater. A .50 water cement ratio will likely reach 4000 psi or greater.

3 MIX DESIGN PROPORTIONING

For workable concrete, a higher water cementitious ratio is typically required when aggregate becomes more angular and rough textured. The presence of air, certain pozzolans, and aggregate proportioning will work to lower the water cementitious ratio; however the most significant reduction in water demand comes through the use of a high range water

What Is Cement, Sand, Aggregate Ratios In Concrete Mixing

We own a excellent album of What Is Cement, Sand, Aggregate Ratios In Concrete Mixing Picture to more inspiration about Coarse Code popular selection premium tons images of the What Is Cement, Sand, Aggregate Ratios In Concrete Mixing photography for free download Ultra HD inventory images for your laptop or android.. Cement, Sand, Aggregate And Water What Is The Ratio Of .

EFFECTS OF AGGREGATE TYPE, SIZE, AND CONTENT .

Tests were conducted by Nallathambi, Karihaloo, and Heaton (1984) on mortar and concrete beams of normal strength to examine the influence of specimen dimension, notch depth, aggregate size (10 mm, 14 mm and 20 mm), and waterto cement ratio on the fracture behavior of concrete.

Mixing Concrete for the Beginning DIYer |

The four basic components should be mixed at the following guidelines in order to produce 3000PSI concrete: one part Portland cement, three parts sand, three parts aggregate, and one part water. It is important to note that the water to cement ratio determines the strength of the substance.

HOW TO DECIDE MAXIMUM SIZE OF COARSE AGGREGATE .

Mar 23, 2015· On the other hand in smaller size aggregates the surface area is increased which increases w/c ratio and lower strength is achieved. In general for strength upto 200 kg/cm 2 aggregates upto 40 mm may be used and for strength above 300 kg/cm 2 aggregate upto 20 mm may be used. Conditions That Decide Maximum Size of Coarse Aggregate to be Used in Concrete

The importance of water/cement ratio in concrete ...

The w/c ratio refers to the ratio of the weights of water and cement used in the concrete mix. A w/c ratio of means that for every 100 lbs of cement used in the concrete, 40 lbs of water is added.

principles of concrete mix ACC Help

Principles of Concrete Concrete Mix Design IS 10262. Concrete. Concrete is an intimate mixture of: Cement, Sand (Fine Aggregate), Coarse Aggregate, Water. New Generation Concrete needs use of Special Materials in addition to above "ADMIXTURES" Admixtures may be Mineral or .

What's the Difference Between Cement and Concrete?

Typically, a mixture is by volume about 10 to 15 percent cement, 60 to 75 percent aggregates and 15 to 20 percent water. Entrained air bubbles in many concrete mixtures may also take up another 5 to 8 percent. Portland cement's chemistry comes to life in the presence of water.

The effect of aggregatetocement ratio and types of ...

To make use of recycled materials to produce ecofriendly ( recycled materials as aggregates) concrete blocks with good quality, it is recommended to prepare the blocks with 50% recycled crushed glass (RCG) and 50% recycled crushed aggregate (RCA) and with an A/C ratio of 4 or below.

Mix design of concrete: Mix design M 40

Jan 28, 2012· p = ratio of fine aggregate to total aggregate by absolute volume f a, C a = total masses of fine and coarse aggregates, per cubic metre of concrete, respectively, kg, and S fa, S ca = specific gravities of saturated surface dry fine and coarse aggregates, respectively

What to Expect When Mixing Concrete With Glass

Jul 05, 2011· The amount of damage inflicted by ASR on concrete depends upon the volume, the piece or particle size, and even the color of the glass. According to a report issued by the Clean Washington Center (CWC), increasing the surfaceareatovolume ratio of glass (in other words, using smaller shards) will reduce the effects of the reaction.

How Does the Ratio of Sand to Cement Affect the Strength ...

How Does the Ratio of Sand to Cement Affect the Strength of Concrete?. The way that concrete is mixed is very important in determining the quality of the final product after it is poured. The exact materials used and the proportion of those materials are both very important. Knowing what ratio of sand to cement to use depends partly on what the...

WatertoCement Ratio and Aggregate Moisture Corrections

May 28, 2010· "Volumetric Batching: First, the 1:2:4 ratio is the ratio of cement to fine aggregate to coarse aggregate, by material volume. There are five parameters we need to identify prior to calculating the mix proportions.

Farm structures ... Ch3 Building materials: Concrete

5 Calculate water cement ratio and cement aggregate ratio. Water cement ratio = (83 kg water) / 100 kg cement = 0 83. Aggregate cement ratio = (882kg aggregate) / 100 kg cement = The water cement ratio indicates that the mix has a basic strength corresponding to .

Grades of Concrete with Proportion (Mix Ratio) Civilology

Grades of Concrete with Proportion (Mix Ratio) We use different grades of concrete for different parts of the building. We could say the grade of concrete is the only thing we do care lot while concreting.

Concrete Mix Design Design Mix Concrete Nominal Mix ...

Jan 14, 2017· Nominal Mix Concrete: This method is generally used when the quality control requirement for design mixes are difficult to execute. As we have explained for normal work, nominal mix concrete can be designed by taking cement, fine aggregate and coarse aggregate in the ratio of 1 .

Mix Design For M35 Grade Of Concrete Civil Engineering

From combined gradation of Coarse aggregates it has been found out that the proportion of 53:47 of 20 mm 10 mm aggregates produces the best gradation as per IS: 383. Hence, 20 mm Aggregates = 619 Kg. And 10 mm Aggregates = 546 Kg

What Are the Mix Ratios for Cement and Sand ...

The basic mix ratio for concrete is one part water, two parts cement and three parts sand. An alternative ratio is one part cement, two parts sand and three parts gravel with enough water added until the mixtures reaches the consistency of thick mud.

mortar What's the best ratio for sandonly concrete ...

1 Answer. Generally, the 1pt cement : 2pt sand ratio is best and will have a 3500 psi compression stress. A 1:3 ratio will have less than 3000 psi. Gravel can actually strengthen the mix... up to 3 parts. The mix of choice (concrete) is 1pt cement :2pt sand : 3pt gravel, because it's .

Latest Posts

- استئجار المهنية معدات في الجزائر

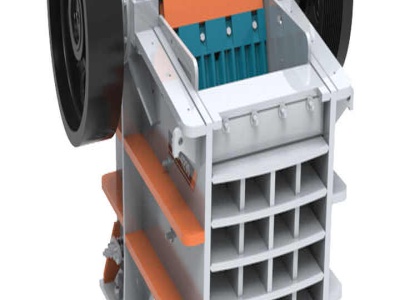

- جدول كسارات الفك

- مصنعي الآلات كادح في الصين

- طحن آلة الصانع المملكة العربية السعودية

- الذهب المعدات إثراء خام

- كسارة فكية صخرية يمنية

- معالجة الرمل المسحوق لصناعة البناء

- كسارات خرسانة مدمجة متنقلة للتأجير في أيرلندا

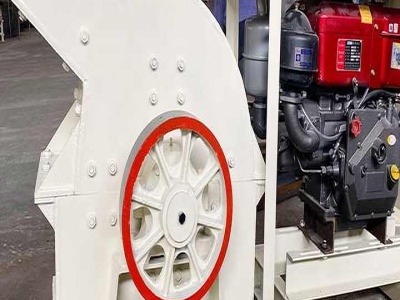

- كسارة تأثير الفحم في الأنجولا

- مصنع تكسير خام الذهب في زامبيا

- المصنعين آلة صخرة محطم

- كسارة الجرانيت في خط معالجة الجرانيت في المملكة العربية السعودية

- لا كسارات الفرز

- سعر آلة الرمل م في الجزائر

- آلة كسارة الفرق

- forged grinding steel ball

- linear vibrating screen for screening powder granules

- cara menanam tanaman di kerikil akuarium

- original jaw crusher for sale

- parker jaw roll crusher for sale

- rock crushing equipment in kenya

- soap detergent plant capacity 300 ton perday

- horizontal and vertical grinding machines

- bakery machines and ovens

- hand grinding machine di indonesia

- south africa gold crusher with conveyor belt

- cme ore crushers

- sandvi stone crusher indonesia

- marine diamond mining

- alat pelindung diri pertambangan