cold mill work roll

Roller Mill Maintenance00

crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds. While each application has some unique aspects, maintenance and operation of the equipment is remarkably similar. Roller mill maintenance can be broken down into three general areas; rolls, bearings, and drives.

Cold Mill DeChocker Machine Concepts

Apr 01, 2018· Cold Mill DeChocker Dechockers support mill backup or work rolls on the or at the neck of the roll. Bearing chock support stands are raised to support the roll chocks allowing removal of the retaining rings and bearing containment components.

Analysis of thrust force in a work roll shifting mill ...

1. Introduction. The shape control mill has been widely used in modern continuous cold rolled strip production line due to the users' high requirement of strip shape quality,, .Compared with other mills, the work roll shifting mill, such as the high crown (HC) mill and the continuous variable crown (CVC) mill, is considered the most effective mill for strip shape control at present.

Steel rolling mill chatter marks Mechanical Acoustics ...

Jan 13, 2011· The mill has 2 work roll sizes (450 mm dia for 150 tons and 650 mm for 400 tons) and 2 backup rolls both 1100 mm dia. Each work roll has a gearbox and 750 KW motor driving it. 3rd and 5th octave type chatter is documented and is speed sensitive.

Review on cold rolling mill roll deformation

Flow Chart 1Production Sequence for Cold Rolling Mill Roll II. REVIEW OF LITERATURE In cold rolling process the main tool is roll and for rolling the desired properties of the roll are playing important role. Hardness, stiffness, load, machinability, rigidity should be in such a way that the tool (roll) should work .

Rolling processes AlMustansiriya University

In cold rolling, the value is around ; in warm working, a typical value is around ; and in hot rolling, m is around Hot rolling is often characterized by a condition called sticking, in which the hot work surface adheres to the rolls over the contact arc. This condition often occurs in the rolling of steels and hightemperature alloys.

Failure Analysis of Rollers in mill stand using Failure ...

Keywords: Rollers, Failure mode Effect Analysis Introduction In rolling mill operation a four roll high stand intermediate mill, twostand pre finishing mill stand tandem mills including two work rolls and two and a tenstand rod finishing mill..In this study more backup rolls are used to decrease force and power of than fifteen failure modes ...

Hard chrome plating of work rolls for cold rolling and ...

Hard chrome plating of work rolls for cold rolling and skinpass. Chrome is very fragile and on these kind of rolls a thick layer will break down because of the big forces involved in the mill. 10 to 20 microns will be ok in most cases. But thickness will be different depending on the stand and depending on the rolls (hardness, diameter,...

Chapter 4 Surface finish and friction in cold metal rolling

In most cold rolling operations, lubricant is used to reduce frictional forces, to protect the roll and strip surfaces, and to act as a coolant. The amount of oil drawn into the roll bite and the initial surface roughness are the critical factors determining friction in the contact and surface finish of the product (Schey, 1983a and 1983b).

Cold Rolled Carbon Steel Tubing | Middletown Tube Works

Strong and Smooth. A cold mill outfitted with specially roughened rollers provides additional processing, giving the steel a uniform, matte finish. Each cold rolled steel tube comes smooth to the touch and readily paintable using essentially any paint system. Available in a .

Ribbon Fatigue Spalling of a Forged Work Roll Used at a ...

Oct 31, 2014· Analysis of inservice catastrophic failure of a work roll in a cold rolling mill of an integrated steel plant has been presented. The roll failed prematurely after giving 64% of its service life. Visual observation of the failed roll revealed a huge spalled region of about 970 mm × 500 mm.

Hard chrome plating of work rolls for cold rolling and ...

Hard chrome plating of work rolls for cold rolling and skinpass 2002. Q. My steel company intends to install a new stateoftheart hard chrome plating plant for plating of work rolls of cold rolling and skinpass mills. Material to be processed: Carbon and alloy steel oiled rolls.

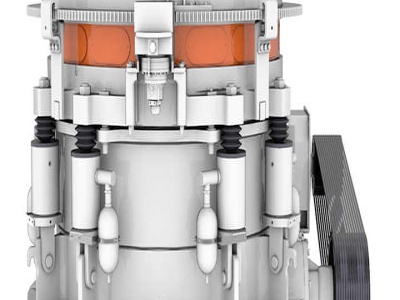

Sendzimir | Products | 20High Mills

The cluster configuration transmits the roll separating force from the work rolls to the mill housing. The small size of the work roll permits superior reductions on very hard materials, such as stainless steel or titanium. Flex Backing Assemblies and Segmented Idler .

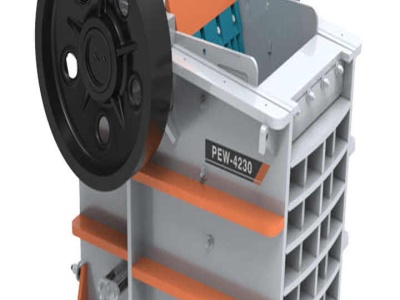

mechanical engineering: Types of rolling mills

A four high rolling mill is used for the hot rolling of armor and other plates as well as cold rolling of plates, sheets and strips. 4: Tandem rolling mills: It is a set of two or three stands of roll .

![camber for 4 hi mill work roll[crusher and mill]](/67bqfrc/1331.jpg)

![camber for 4 hi mill work roll[crusher and mill]](/67bqfrc/682.jpg)

camber for 4 hi mill work roll[crusher and mill]

camber for 4 hi mill work roll. Rolling (metalworking) Wikipedia, the free encyclopedia. A fourhigh mill has four rolls, two small and two large. ... 5 Hi Hot Rolling Mill, 4hi Work Roll Drive Cold Rolling Mill, 4HI Rolling Mill and 5 Hi Rolling Mill offered by Tirupati ...

Work Rolls for Cold Rolling Mill Rolls steeltechnology

The size and diameter of these work rolls differ as per the client's requirement. Few specifications offered by Vijay Chill Rolls in the work rolls range include the plate work rolls, 6 Hi Mill work rolls and 4 Hi Mill work rolls. These work rolls are of prime quality and hence are highly preferable.

Facilities 5Stand Cold Reduction Mill

than can be rolled by the Hot Mill. Cold Rolling CSI's cold reduction mill is a series of five rolling mills, or 'stands'; hence the name "5Stand". Each mill stand has two work rolls about two feet in diameter, which are driven by powerful electric motors (totaling over 25,000 horsepower) and sandwich the steel to reduce the thickness.

Mill Reversing Cold Rolling Mill (CRM) Manufacturer from ...

Manufacturer of Mill Reversing Cold Rolling Mill (CRM), Reversing Cold Rolling Mill (Crm), Skin Pass Mill (SPM) offered by Rollpro Technologies Pvt. Ltd., Thane, Maharashtra.

A Series Of Cold Rolling Operations Are To Be Used ...

A series of cold rolling operations are to be used to reduce the thickness of a plate from 50mm down to 25mm in a reversing twohigh mill. Roll diameter = 700mm and coefficient of friction between rolls and work =

Cold Mill Work Roll: ColdRolled Steel Rollers – Cold Mill ...

The minimum diameter leveler roll that Orient is manufacturing is of 20mm dia. Since the application is concerned with finished coils, it is very important that the rolls meet the following requirements: Good surface finish; Minimum variation( cylindricity and ovality) in the roll diameter; Ability to absorb bending forces and retain original shape.

Cold Mill Rolls | Work Rolls | Backup Rolls | Backup Rolls ...

Cold Mill Rolls, Work Rolls, Backup Rolls, Backup Rolls Sleeves, Induction Hardened Rolls, Rolls For Cold Rolling Mills, Hi Rolls, Skin Pass Rolling Mill Work Roll Who We are : We are manufacturer of rolls and roll assemblies complete with bearing assemblies.

cold rolling mill work roll | tradekorea

tradeKorea is a online B2B trade website offers you matching services to connect buyers and suppliers. Establish reliable relationship between buyers and suppliers through our matching services and find new business opportunities through various online exhibitions.

Tata Steel begins work on Phase II at Kalinganagar with ...

Jun 21, 2018· Tata Steel begins work on Phase II at Kalinganagar with new Cold Roll Mill The mill will be capable of producing steel of tensile strength as high as 12,000 MPa (mega pascal) and plates of 1870 metre wide and up to 3 mm in thickness.

Latest Posts

- عملية تعدين خام البوكسيت

- تستخدم الدولوميت تأثير كسارة سعر السودان

- آلات تكرير المعادن الثمينة

- كسارات الحجر المذي

- كولومبيا مصنع لتجهيز الفحم

- شركة كسارة الصخور مصر

- تصميم محطم كسارة البوكسيت

- الذهب المحمول مصنع لتجهيز بيع المملكة العربية السعودية

- شركة تعدين خام الحديد في المملكة العربية السعودية

- المعدات عملية التعدين مصنع

- المصنعة من النباتات إثراء في بيرو

- كسارة خام الذهب المحمولة

- م آلة تصنيع الرمل

- 50 طن السعر محطم محطم المملكة العربية السعودية

- نوع مختلف من آلة طحن

- coal screen design pdf

- bit crushers download

- impact crusher use in srilanka

- block cutter block cutter manufacturers exporters on for sale

- dil kehaa hai chal nuse mli

- convenientconvenient cheap stone mobile crusher

- project report on stone crusher unit pdf in dhule

- marble production equipment in ethiopia

- allu excavator bucket screener

- aggregate crushers south africa

- diamond grinding ds

- latest 350 tph crusher machines

- ball mill 2 conveyor belt 2 zimbabwe

- what is concrete crushing machine

- ballast crusher s