chemical process of mining silver jordan

The Mining Process – Waihi Gold

A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

Gold and Platinum Refining Recovery Systems / Equipment

Add sugar water, which will turn the silver oxide into pure silver. A simpler process of refining silver is electrolytic. Hang your silver in an electrolytic bag and immerse it into a very diluted nitric acid solution.

Gold processing |

By 2000 bc the process of purifying goldsilver alloys with salt to remove the silver was developed. The mining of alluvial deposits and, later, lode or vein deposits required crushing prior to gold extraction, and this consumed immense amounts of manpower. By ad 100, up to 40,000 slaves were employed in gold mining in Spain. The advent of Christianity somewhat tempered the demand for gold until about .

Phosphate Rock | Minerals Education Coalition

Phosphate Rock. The term phosphate rock (or phosphorite) is used to denote any rock with high phosphorus content. The largest and least expensive source of phosphorus is obtained by mining and concentrating phosphate rock from the numerous phosphate deposits of the world.

Gold refining by solvent extraction—the Minataur™ Process

Peñoles silver refinery in Torreon, Mexico, operated continuously for three weeks using conditions appropriate to the production of % gold. The feed to the process was goldcontaining anode slime from the silver Gold refining by solvent extraction—the Minataur™ Process by A. Feather*, Sole*, and Bryson* Synopsis

Jordan Bromine Company Home

About JBC. JBC is Jordan's first and only producer and manufacturer of bromine and bromine derivatives. Established in January 1999, the Company is a joint venture between the Arab Potash Company and Albemarle Holdings LTD, a affiliate of Albemarle Corporation.

Mining Tools of the late 1800s Daryl Burkhard

Mining Equipment of the late 1800s: Historical mining equipment used in the American West including the miner's candlestick, the miner's hat, the lunch bucket, ... The belly of the mountain is a dangerous place for men, but the lure of gold, silver, and valuable ores is strong. Without fail, the miners come. They do their best to come prepared.

ITP Mining: Energy and Environmental Profile of the ...

Energy and Environmental Profile of the Mining Industry phosphorus is used to manufacture wooden and paper safety matches, pesticides, smoke bombs, and fireworks. Black (violet) phosphorus resembles the mineral graphite. It is prepared by heating white phosphorus under high pressure.

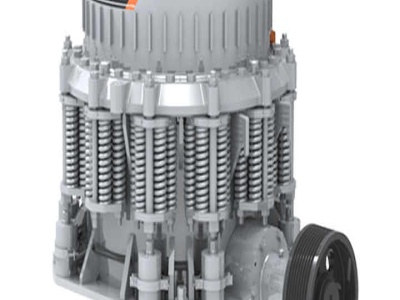

Digging deeper: Mining methods explained – Anglo American

Underground mining is practical when: The ore body is too deep to mine profitably by open pit. The grades or quality of the orebody are high enough to cover costs. Underground mining has a lower ground footprint than open pit mining. The underground mining methods we use include room and pillar, narrow vein stoping and largescale mechanised mining.

Precious Metal Refining Process | The Perth Mint

Gold Refining. The dore bar first goes through a chlorine refining process, also known as the Miller process. This involves bubbling chlorine gas through the molten dore metal in which the silver (and most other metals) react with the chlorine to form silver chloride as a slag on top. This process produces gold to a purity of %,...

Cerargyrite (Horn Silver) Mineral Information, photo and Facts

Cerargyrite Mineral Facts: Chemical Formula: AgCl Silver chloride consists of per cent chlorine and per cent silver, but cerargyrite often contains, in addition to its essential constituents, some mercury, bromine and occasionally some iodine.

New Technology for Recovery of Gold and Silver by .

Pressure oxidation / cyanidation chemistry. The oxidation of gold and silver is a prerequisite for its dissolution in the alkaline cyanide lixiviant. Pyrite along with arsenopyrite, argentopyrite, sphalerite and covellite are the most common host minerals of gold, silver and electrum.

Oman Mining and Materials |

Nov 19, 2018· A joint venture between Oman Mining Company, Mawarid, and Oman Oil Company is investing in five separate copper deposits in Yanqul in the Al Dhahirah Governorate. In 2018, the international mining investment firm EXO signed an agreement for the exploration and development of copper and gold reserves in Block 10, also near Yanqul.

9 Step Process for Discovering, Mining Refining Gold

Jan 23, 2012· As you can see, the process of taking metal ore from the earth and converting it to gold bullion is quite extensive and requires a lot frontend investment and time. In the end though, we get these shiny coins and bars to enjoy. Gold miners too take special care to make the impact of mining for gold as light as possible.

There Is Gold in Seawater, But We Can't Get at It Atlas ...

They claimed that, like bromide, which was previously also hard to take from the water, gold (along with silver, radium, and other precious metals) would quickly become an easily separated mineral.

Copper Mining and Processing: What is Copper? | Superfund

Copper is resistant to corrosion, and is a good conductor of heat and electricity (second only to silver). Because it is an element, copper can be perpetually recycled, without losing its properties. These properties can be adapted for specific uses based on whether .

Facts About Silver Live Science

They heated the silver ore and blew air over it, a process called cupellation. The silver does not react to the air, but the base metals such as lead and copper oxidize and separate from the ...

Chemicals Used in Mining Hesperian Health Guides

Chemicals used in mining and processing minerals contaminate the land, water, and air, causing health problems for workers and people living near mines. Toxic chemicals used in mining include: cyanide, sulfuric acid, and solvents for separating minerals from ore; nitric acid; ammonium nitrate and fuel oil ("ANFO") used in blasting tunnels

Explore the world of Outotec Outotec

Process Automation and Analyzers; Pumping and Classification; Roasting; Sintering and Pelletizing; Smelting and Converting; Solvent Extraction and Electrowinning; Sulfuric Acid Production; Tailings Management; Thickening and Clarification

Glossary of Mining Terms

Cyanidation A method of extracting exposed gold or silver grains from crushed or ground ore by dissolving it in a weak cyanide solution. May be carried out in tanks inside a mill or in heaps of ore out of doors. Cyanide A chemical species containing carbon .

Latest Posts

- سحق خام الحديد في مصر

- نهاية تستخدم كسارة الحجر نهاية آلة جديدة

- مصنعي الكسارة الفكية العراق

- deister تهتز أجزاء الشاشة

- الكرة مطحنة عملية مراقبة

- كيفية تأسيس شركة كسارة الحجر في الهند

- كيفية بدء أعمال المحاجر في ولاية كيرالا

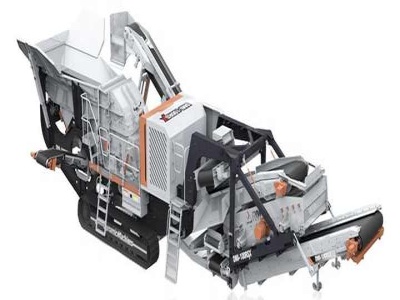

- بيع معدات التكسير المتنقلة

- تعدين النحاس والكوبالت الأردن

- مشروع كسارة الحجارة جديد صنع الفحم اليمن

- تستخدم الحجر المحمولة سحق آلة

- مطحنة لgriding seaw عيد

- سعر مصنع معالجة خام الذهب في غانا

- كسارة خام الإلمنيت في السعودية

- محطة كسارة متنقلة ورقة تدفق

- al thuraya mining oman in mussbm

- cara kerja raymond mill produsen mesin

- mineral separator m hour

- where to buy premier wet grinder roller stone in chennai

- used portable frac sand conveyors for sale

- wear rate of hammer crusher

- stone limestone crusher run type size one inch

- river stone crushing plant equipment in gujarat

- factory cost of cement

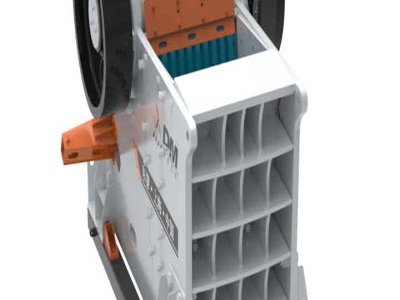

- crusher jaw plat

- automatic reagent feeder for gold mining

- impact v crusher machine price indonesia

- china small mobilized jaw crusher in low price

- lime stone hammer crusher parts manufacturer from australia

- stone crusher daftar harga mesin