cement grinding typically

Modern Processing Techniques to minimize cost in Cement ...

configuration was typically to suit ball mill applications for grinding. Moreover, the ... whereas Cemax Mill is mainly for cement grinding. The mill can be used for pregrinding and finish grinding. This millsystem claims to have advantages of ball mill, roller mill and roller press in

EnergyEfficient Technologies in Cement Grinding | IntechOpen

In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given. A case study performed on a typical energyefficient Horomill® grinding ...

Concrete Floor Grinding: Concrete Staining: Stained ...

Concrete grinding, staining sealing from Black Rhino is a great economical alternative to the full 10 step mechanical polish service. The grind seal option is very popular in a number of commercial and industrial applications like at manufacturing facilities, retail establishments and at .

CEMENT GRINDING AID COMPOSITION Dow Global .

Nov 26, 2015· In some embodiments, the amount of grinding aid composition in the cement mix is weight percent or less. One of the advantages of the invention is that it provides increased cement grinding efficiency to a cement mix without the need for other, more complex or more expensive grinding .

old grinding mills for cement – Camelway Crusher Sand ...

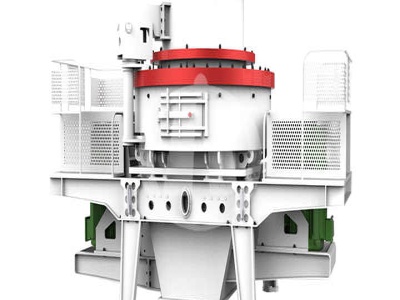

Aug 24, 2018· Optimization of Cement Grinding Operation in Ball Mills. Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball .

Concrete Floor Grinding Melbourne | Concrete Sealing ...

Concrete Grinding Melbourne Some concrete floors, typically those of poor strength cannot be mechanically polished. This is where a grind and seal is the next best option. This method of polished concrete requires us to grind down to your desired exposure levels and then instead of naturally polishing the concrete we coat it with either ...

Cement Production The Concrete Portal

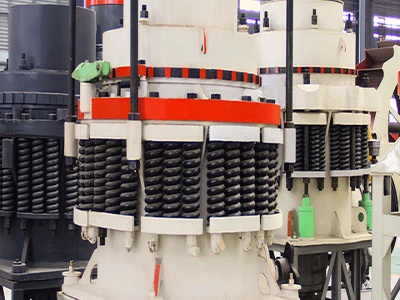

Grinding is done in different types of grinding equipment, such as a ball mill (see Figure 6) or in more efficient vertical roller presses; in a ball mill, the particles are crushed by the impact of steel balls. Gypsum is an essential additive, as it acts as a set regulator for the cement.

RIDGID 7 in. 24Segment Turbo Cup Grinding WheelHD ...

Designed for grinding concrete masonry and a variety of other applications. The double row configuration provides a smoother finish and more stable platform than traditional single row cup wheels. More + Product Details Close. 7 in. Pro Series Spike Grinding Wheel, Wet / Dry, 5/8.

WOA1 Cement grinding aid Google Patents

Such cement grinding aids are typically selected from the class comprising glycols such as alkylene glycols, amines or aminoalcohols For example, US 5,084,103 describes trialkanolamines such as tri isopropanolamine (TIPA) or N, Nbis (2hydroxyethyl) N (2hydroxypropyl) amine and tris (2hydroxybutyl) amine as a grinding aid for clinker.

Cement Grinding In Vertical Mills

Optimization of Cement Grinding Operation in Ball Mills. Optimization of Cement Grinding Operation in Ball Mills. Contact Us » . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills.

Increasing cement grinding capacity with vertical roller ...

Increasing cement grinding capacity with vertical roller mill technology Abstract: ... However, in many cases these same plants have chosen to use very traditional technology for finish grindingtypically a ball mill and separator. With today's power price issues in the US, and the large experience base that the rest of the world has with the ...

Concrete grinding, Principles of grinding, Types of grinders

Some machines contain six discs, typically with a reduced diameter. However, these machines are designed more for concrete polishing rather than preparing a surface for a floor covering. Depending on the type of tooling you're using, the disc will have slots, holes or other mounting fixtures to take the diamond segments or plugs.

The Dusty Dangers of Concrete Cutting Grinding ...

Concrete cutting and concrete grinding are very dusty jobs in the construction industry, both posing a serious health risk to masons. Masonry blocks, bricks, and concrete slabs contain concentrated amounts of crystalline silica. When these materials are drycut they release silica containing dust into the workers' breathing zone. Regular exposure to this hazardous dust can

Vrm Presentation | Mill (Grinding) | Cement

ROLLER MILL. Used in cement industry Vertical Mills used for Pregrinding of clinker (lumps to coarse powder) Finish grinding (lumps to powder) of Coal/Petcoke for kiln Raw materials for kiln Cement, OPC or mixed Slag, pure or mixed VRM Functions Vertical Roller Mill (VRM) Details feed gate (air lock) mill casing water injection dam ring louvre ring nozzle of material scraper mill outlet ...

Concrete Grinding Michigan | North American Coating Solutions

Finish Off Your Floors With Professional Concrete Polishing From North American Coating Solutions; Explore Other Concrete Restoration Services To Bundle With Your Concrete Grinding. Concrete grinding is typically a preparatory step for some form of concrete floor restoration.

Improvement of cement performances through the use of ...

Cement Additives Division 1 Improvement of cement performances through the use of grinding aids in vertical roller mill 'Arcangelo, – Mapei SpA, Milan, Italy Abstract Due to the stringent requirement of energy saving, the use of vertical roller mills for cement grinding .

Pacific Grinding :: Concrete Polishing

Polished concrete is achieved by treating concrete with chemical hardeners and grinding concrete with progressively finer diamond grit tooling. Concrete is typically considered ground and honed until reaching the 400grit level. Once the concrete has been ground with 800 and above tooling, it is considered polished.

Latest Posts

- تعدين الذهب سعر معدات تكسير

- sks كسارة sclient psy ab

- المصنعة كسارة الفك في بيون

- الشركة المصنعة محطة كسارة المحمول في مصر

- الساخن مخروط مبيعات محطم عالية الكفاءة

- بيع كسارة الصخور الفكية الصغيرة

- غربلة اهتزاز خام الحديد

- مطحنة الكرة الذهبية الصغيرة للبيع

- كسارة جوز الهند وآلة طحن

- كسارة خام الحديد المحمول في مصر

- شبكة غربال صغيرة تهتز

- حجر سحق الرأس الغربي

- سحق نفايات البناء محطم

- كسارة الحجر 75 طن في الساعة

- شراء كسارات الذهب للسودان

- centrifuge for gold recovery

- simons roller mills

- cheat soul crusher

- raymond high penghancur html

- comandclem nigeria limited my doubts

- equipment for crushing chemical products

- concrete line pump for sale

- hammer crusher dimension for pc x

- material for ball mill concrete

- belt conveyor covers

- pabrik semen di nomor kontak sindh disertai

- calcium carbonate grinding machines india

- stone jaw crushers 16 10 prices in india

- batu jaw crusher untuk dijual di afrika selatan

- concentrator crusher assembly risk assessment to use free download