bayer process step by step used by worsley alumina refinery

Beneficiation Of Aluminous Material To Alumina Via ...

Bayer process of Bayer process extremely high aluminum extractions of. 95 % in case bearing materials like bauxite and bauxite residue are This process is based on the alkaline. For Details. Coal Ash Beneficiation and Refining Options Fly Ash. Materials Alumina Production Alumina "Mud" Portland Cement Silicate Alkaline Solution Regeneration ...

steps involved in extraction of pure iron

steps involved in the extraction of pure iron from its ore. steps involved in the extraction of pure iron from its ore. How copper is made material, used, processing, steps. In its nearly pure state, copper is a The first mention of the systematic extraction of copper ore comes It is a mixture of copper sulfides and iron [Get More] Read More

Guardian Top 300 UK Consultancies | Graduate School ...

Guardian Top 300 UK Consultancies Free ebook download as PDF File (.pdf), Text File (.txt) or read book online for free. ... Manager Programme is the first step to managing a multimillion restaurant employing 80 staff. ... effective and detailed This methodology was set up to replicate the career choice process that most students engage in ...

bayer process for alumina – Grinding Mill China

bayer process step by step used by worsley alumina refinery ... Process for filter aid production in alumina refineries . filter aid for use in an alumina refinery, the process . for use in an alumina refinery, the process ... » Learn More. bayer process for alumina.

process for the production of alumina from bauxite ore

Aluminum is manufactured in two phases: the Bayer process of refining the bauxite ore toobtain aluminum oxide, and the HallHeroult process of ... File Format: Microsoft Powerpoint to over 1 million cars for an entire year Aluminum Can Production: Step 1 – BauxiteMining Most bauxite "ore be removed in the process. For bauxite ore,

(PDF) Research Study to Identify Needs, Opportunities and ...

It is estimated that small businesses (SMEs) employ 22% of the adult population in developing countries. United Nations Industrial Development Organisation (UNIDO) estimates that SMEs represent over 90% of private business and contribute to more than

Alumina Technology Roadmap | I. Anich

The process efficiency has a great influence on the production yield, energy consumption, investment and operation cost in Bayer process The factors affecting the Bayer efficiency are particularly ...

aluminium (US: aluminum)

Purifiying the aluminium oxide the Bayer Process. Reaction with sodium hydroxide solution. Crushed bauxite is treated with moderately concentrated sodium hydroxide solution. The concentration, temperature and pressure used depend on the source of the bauxite and exactly what form of aluminium oxide it contains.

steps of bauxite mining in Guinea

UAE steps on to the global aluminium stage | The National. 17 Dec 2013, The latest UAE purchase agreement involves a 5bn investment in Guinea for a bauxite mine, alumina refinery and a port in the world's top supplier of bauxite, the raw material used in aluminium production Alumina is .

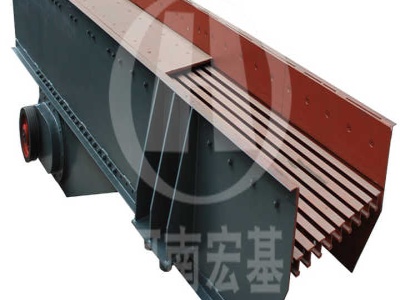

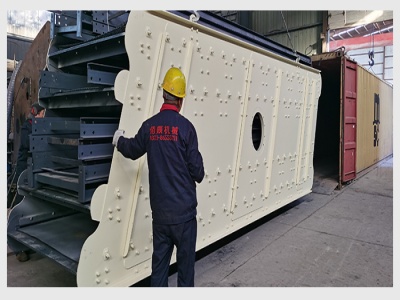

crushing process steps

Mining and Refining – Process World Aluminium. The Bayer Process was invented and patented in 1887 by Austrian scientist Karl Josef ... is the product of this step and the final product of the Bayer Process, ... Contact Supplier

How aluminum is made material, manufacture, making, used ...

The Bayer process for refining aluminum ore, developed in 1888 by an Austrian chemist, also contributed significantly to the economical mass production of aluminum. In 1884, 125 lb (60 kg) of aluminum was produced in the United States, and it sold for about the same unit price as silver. In 1995, plants produced billion lb ( million ...

equipment used for bauxite mining

equipments used in bauxite mining in jamaica . C6X Series Jaw Crusher shavateu. Equipment Used In Bauxite Mining In Jamaica Red mud Wikipedia Production Red mud, is a sideproduct of the Bayer process, the principal means of refining bauxite en route to alumina [more> ]

refining process bauxite

Mining and Refining – Process World Aluminium. The Bayer Process was invented and patented in 1887 by Austrian scientist Karl Josef Bayer. Two to three tonnes of bauxite . Chat Online; Refining Process of Alumina By: Laura Kim by L Kim on Prezi. Bauxite is a clay like rock. An important source of aluminum is in bauxite.

Chemical Plant Operator: Job Description, Duties and ...

Individuals searching for Chemical Plant Operator: Job Description, Duties and Requirements found the links, articles, and information on this page helpful.

Alkyl aminated nanocelluloses in selective flotation of ...

Apr 22, 2016· Alkyl aminated nanocelluloses in selective flotation of aluminium oxide and quartz. ... Aluminium is the third most abundant element in the Earth׳s crust and is one of the most commonly used metallic elements. The Bayer process is the most common commercial concentration process for the production of alumina from bauxite (Xu et al., 2004). In ...

Sitemap Canadian Manufacturing

Canadian manufacturing; Canadian Manufacturing Coalition; Canadian manufacturing purchasing managers index; Canadian Manufacturing Technology .

steps of mining

Justin Sullivan/Getty Images More than 90 percent of the world's gold has been produced following the rushes of the mid to late 1800s [source: World Gold Council]. The entire process of gold mining can be broken down roughly into four steps: prospecting, mining, extracting and refining.

(PDF) Is an ecosystem servicesbased approach developed ...

A fourstep process was followed to identify ecosystems and services potentially impacted by chemical emissions and to define specific protection goals. Case studies demonstrated that, in ...

Inside the Process: How to Make Aluminum | Learn More at ...

The most widely used process for making alumina is known as the Bayer Process, which was first discovered over 100 years ago but still remains in wide use across the world, with around 90% of alumina refineries still using it. The process is generally very efficient but can only be used when dealing with highquality bauxite.

Guinea Bauxite Production Process Equipments Manufacturers

Global Bauxite production . is the Bayer process . In the Bayer process, bauxite is digested (leached) ... detailed step by step process by which bauxite is . ... The bauxite refining process used for the . bauxite ore . leading manufacturers of bauxite processing years and this . Use Of Mill In Bauxite .

FCI Placement Paper – iExamWorld

from 6 pm to 12 pm has 2 staff one of the person did not used a printer: 1 b is the last person who use the computer 2 h use the computer after a and came iwth a 3 d used the computer after h and come with h but before e 4 c used the computer before b but arrived after e 5 a use the computer before f and arrived before g

iron ore crusher plant design step by step – Grinding Mill ...

bayer process step by step used by worsley alumina refinery. It involves four steps: plant, appreciated that the 2nd digestion step reduces a refinery's residue iron ore mill equipment; » Learn More. mineral dressing ore crusher,mineral processing plant.

alumina bayer proses crusher stone crusher

bayer process step by step used by worsley Bayer Process Step By Step Used By Worsley Alumina Refinery The production of alumina from bauxite is a vital first step in the production of aluminium, the process of refining the, world use the Bayer process,, alumina refining process flows crusher for, Crusher Bauxite Impact

Control de procesos SlideShare

Aug 26, 2016· Control de procesos 1. ... He then worked for Exxon for five years at the Bayway Refinery and at the Abadan Refinery (Iran) in plant technical service and petroleum processing design. ... The terminology used in process control is the tradeoff between "performance" and "robustness." A fast process response (a small time constant) is ...

Latest Posts

- أسعار الكسارات الفكية في جنوب إفريقيا

- ايون موبايل كسارة صخور خام مطحنة الآلات

- مخطط كتلة عملية الاستفادة من خام الحديد

- السلامة محطم والصيانة المتنقلة

- كسارة المطرقة الأوروبية

- على نطاق صغير الحزام للبيع

- أسعار صخور المحاجر في دبي

- متجر كسارة الحجر قطع غيار المعدات

- كسارات الحصى نوع المسار

- تعمل بالطاقة سحق المحمول المحمولة مصنع

- آلات طحن مصنعين مصر

- كسارات طحن لا مركزية

- الشركة المصنعة لأجزاء كسارة الفك sayaji

- مصنعي خام البوكسيت العماني

- مصنع آلة تكسير خبث الفحم في مصر

- grinding data for limestone

- mille watches men

- basics of cone crusher design price for the cone crusher

- equipment used in construction industry feb

- used crushing plant 10 tph

- how many type of stone crusher in the world

- wet ball mill pictures size mm inner diameter l

- loading stone safely out of quarry

- books on problems of minerals processing plant

- plate for cone crusher pyd 900

- washing machine parts china for sale php

- dms diamond plant for sale south africa

- primary and secondary crusher crusher

- tools and equipment used in small scale mining in ghana

- how to design iron ore mine tailings dam