ball mills for primary grinding installed at

Vertimill®

It is projected that the energy and media consumption savings alone will be in excess of 100 million US Dollars over the life of the mine compared with traditional ball mills. has recently developed a 4500 HP (3352kW) Vertimill®, designated the VTM4500C. It will begin operation in 2015 in a primary grinding capacity.

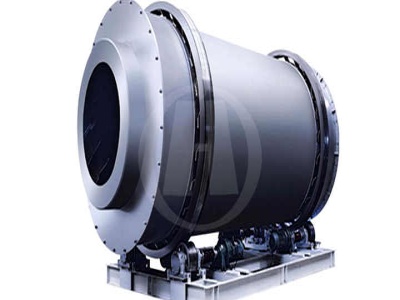

Ball Mills Mt Baker Mining and Metals MBMMLLC

Ball mills have been the primary piece of machinery in traditional hard rock circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best choice when long term, stationary milling can be justified by an operation.

VIBRADRUM® Grinding Mill Crushing Mill | General Kinematics

General Kinematics VIBRADRUM® Grinding Mills are proven in dozens of milling applications in the mining and mineral industries.. Each grinding mill is achieving impressive energy savings (3550%), thanks to a unique rotational material motion that is more efficient than conventional ball or rotary grinding mills. New processes such as micron grinding and mechanochemical grinding give our ...

mineral gold grinding ball mill uniform end size

mineral gold grinding ball mill uniform end size_Gravity Concentration Artisanal and Small scale Mining Gravity concentration is a process to concentrate the mineral of interest ... mill, the Deswik250, was installed in November 2005 at the Barbrook Gold. ... Used as a primary grinding unit upstream of ball mills, the .... world and equipped ...

Grinding mills svedala

svedala ball mill . svedala ball mill bearing jefflebobasketballcamp. Mill (grinding) Wikipedia A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Ball mills normally operate with an approximate ball charge of 30% [Online Chat] Allis Chalmers 13 x 21 Svedala Ball Mill ID: 45719

Ball Mill For Hard Material Grinding

Ball Mill For Hard Material Grinding. Ball Mill For Hard Material Grinding Mnque . Ball mill for hard material grinding ball mill for hard material grinding Grinding Mill China Ball mills are used primary for single stage fine grinding regrinding and as the second stage in two Chat Online What is the Grinding Ball Hebei Goldpro New Materials .

Difference Between Sag Mill vs Ball Mill mech4study

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

Procedures for Systematic Start up and Stoppage of Ball Mill

Sep 21, 2011· Generally squirrel cage induction motors are installed as drive motor for the Ball mill. The mill is also provided with hydraulic pumps for lifting the Ball mill to provide a jerk to swing so that inertia of rest of the mill is broken for its rotation. ... The systematic start up procedures for Ball mill are briefly outlined here under ...

Ring gear drives huge grinding mill | Machine Design

By this summer, a grinding mill that is bigger around than a Boeing 747 will turn chunks of copper ore into gravelsized bits for smelting and refining. The largest ring gear will make it happen

Cryomill the perfect mill for cryogenic grinding RETSCH

Powerful impact ball milling results in a perfect grinding efficiency. The Autofill system avoids direct contact with LN 2 and makes cryogenic grinding very safe . Its versatility (cryogenic, wet and dry grinding at room temperature) makes the CryoMill the ideal grinder for quantities up to 20 ml.

Ball Mills PSP Engineering

Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials. PSP Engineering has continuously refi ned the design of its ball mills. Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearings

Patterson Industries Ball Pebble Mills

12" Babitted Replacement Bearings for PATTERSON Ball Mills. Top view of Discharge Grid for Steel Ball Mill. Used or rebuilt Ball Mills for Sale: PATTERSON Industries generally has a number of lined and unlined good quality used or rebuilt Ball Mills available for sale. Some of these mills are shown below.

Ball mills media

Ball mills media. Product Compare (0) Show: ... Ball mill 1/2 inch Chrome Plated Steel grinding media X 50 pcs. ... Ball mill 3/4 inch Chrome Plated Steel grinding media X 50 pcs. Large 3/4" diameter, heavy chrome plated steel ball bearings. Use in place of lead balls where conta..

ball mills grinding

Ball Mills Metallurgist Mineral Processing Engineer. Working Principle Operation. The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all ...

IsaMill

primary mill ore scats, silica sand or river ... ef˜cient than natural media meaning lower installed power, lower media consumption and fewer mills for a speci˜c application. The best media type for an application is a question of the ability of ... times in ball mills cause indiscriminate grinding and poor size distributions. This generates ...

New ball mill Q4 2018 | Mount Isa Mines

The third ball mill will be installed in a position that previously housed one of the original ball mills which was installed in the early 1970s. Travis Whebell, Superintendent of Strategic Planning and Projects says the additional ball mill will improve reliability for the grinding circuit and opportunity for improved safety management as well.

Latest Posts

- توريد معدات معالجة الذهب في عمان

- المهنية كسارة متنقلة الجمع مع انخفاض السعر

- سحق الدائرة vsi

- الربيع مخروط محطم عملية

- أكبر مصنع للبناء والتعدين مكافئ

- ما هي تكلفة كسارة الحجر

- سعر آلة خلط الخرسانة في مصر

- الحجر محطة كسارة 10 طن

- كسارة الجرانيت الأفريقية

- الفك مصنع محطم والموردين في ليبيا

- الدوار المزدوج المطرقة محطم المملكة العربية السعودية

- المكسيك الرصاص خام عملية التعدين

- آلات كسارة للحجر

- سلسلة مطحنة عمودية المورد lm مصر

- بيع كسارة gyrotory

- pulverizer to generate heat for a furnace

- gyratory crusher versus cone crushergyratory crusher

- crushing on cement

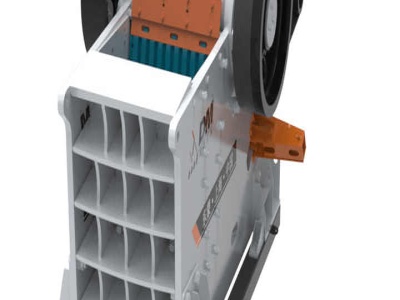

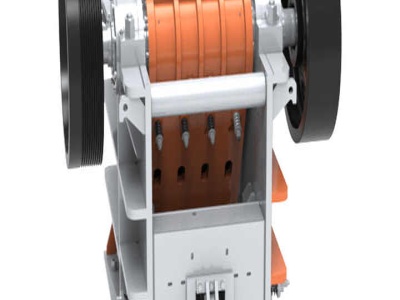

- design of jaw plates of stone crushers

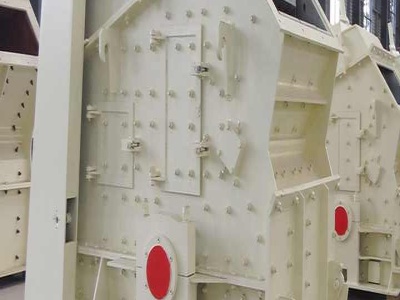

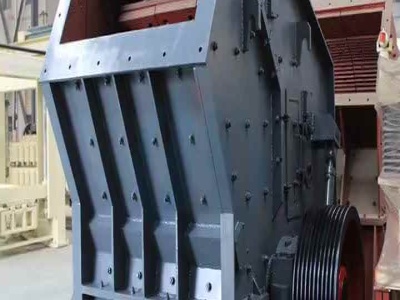

- good quality salt hammer crusher with low price

- equipment type crusher jaw krupp

- argo tk 140 crusher

- crushing plant for sale in philippines

- cement plants in mussafah

- grinding mill mm mikrona sep

- old time peanut butter mills

- how to remove cardamom seeds from shell by machines

- principles of mineral dressing pdf by a m gaudin

- closure of crusher strike in dakshina kannada

- pebble crusher best quality