ball mill liner thickness measurement tools

Autogenous mills, semiautogenous mills and ball mills for ...

supported grinding mills up to the largest sizes. SAG/ball mill circuit incorporating pebble crushers and a POLYCOM® highpressure grinding roll. SAG and ball mill for gold ore grinding. One of three SAG mills with m diameter and 2 x 4000 kW drive power. These mills operate in conjunction with ball mills for iron ore grinding in Iran.

Liner Material Specification Ball Mill Specification

Ball Mill Liners View Specifications Details of Mill . Ball mill liners are the equipments which are used for the installations inside the mills on its inner surface to provide a strong, efficient and tensile lining over it which are further useful in grinding and breaking down the big particles into small and tiny particles in a very ...

BALL MILLS Zimaksan Co

BALL MILLS Very low cost of operation and maintenance High quality production with high capacity Very simple conditions for maintenance Ball mills are the best and most effective method for crushing and powdering a variety of dry and wet materials, including minerals, types of building materials, sand and cement, lime and ceramics, and many other [.]

torque ball mill calculation YouTube

Mar 25, 2019· The Effect of Ball Size Diameter on Milling Performance Open ...A laboratory size ball mill was used with ball media of sizes 10 m.. ... the mill was loaded with kg of the balls as ...

ball mills height

Using a ball mill and parallel tool path with a fixed step over am I overlooking the resulting scallop height readout in the settings anywhere? ... Ball Mill Liner Design 911 Metallurgist. ... height above the liners about twice the liner thickness. Contact US Optimization of mill performance by using online ball ... (SciELO) SA. measurement or ...

Optimisation of an industrial scale ball mill using an ...

chromite rich fraction through the ball mill. This circuit is typical of a UG2 plant in which maximum silicate with minimal chromite breakage is targeted. As a result of the circuit change an opportunity for optimisation around the industrial scale ball mill was considered for this study.

Cutting Forces Calculation and Experimental Measurement ...

Cutting Forces Calculation and Experimental Measurement for 5axis Ball End Milling ... (CIRP CMMO) Cutting Forces Calculation and Experimental Measurement for 5axis Ball End Milling S. Bolsunovsky a, V. Vermel a, G. Gubanov a * a Central Aerodynamics Institute (TsAGI), Science and Production Centre, building 1, Zhukovsky Street, Zhukovsky ...

BALL MILL LINER HAVING BRICKS WITH WEAR INDICATORS ...

Feb 23, 1971· BALL MILL LINER HAVING BRICKS WITH WEAR INDICATORS ... as by measuring the interior of the ball mill container, because the wear varies considerably for different portions of the container. ... The thickness of the section 40 may exceed that of the sections 28 and 34 but again will not normally exceed approximately onethird the thickness of ...

(PDF) A structured approach to modelling SAG mill liner ...

A structured approach to modelling SAG mill liner wear monitoring wear ... Measuring the thickness of the liner Figure 6 illustrates the extremes cases for given similar profiles; CASE B is ...

ball mill liner China HS code import tariff for ball ...

Latest China HS Code tariff for ball mill liner Tariff duty, regulations restrictions, landed cost calculator, customs data for ball mill liner in ETCN. China customs statistics trade data.

What Is The Plate Thickness For Ball Mill Discharge Chute

In other words the diameter of a ball Mill is the measurement inside the average thickness of new liners—not inside the shell as designated by some manufacturers. ball mill heads and trunnions Ball mill feed and discharge heads are detachable, cast of Meehanite metal of ample thickness, either of GA or GC, depending on the size of mill ...

Mill Kiln Manufacturers India Ashoka Machine Tools

Mill Liners Ashoka manufacture a finest range of mill liners in standard quality and thickness. We do customize them as the client requires on bulk order. These are popularly used in metal casting, cement, mining and even dyeing industries. It is used to raise the temperature of the material in a continuous process especially in heavy duty ...

User talk:Alex Doll

Ball and liner wear benchmarking. Ben Burger, Luis Vargas, Hamer Arevalo, Sergio Vicuna, Jim Seidel, Walter Valery, Alex Jankovic, Roberto Valle and Eduardo Nozawa, YANACOCHA GOLD SINGLE STAGE SAG MILL DESIGN, OPERATION, AND OPTIMIZATION, SAG 2011 . Singlestage SAG mill.

Morrell Cmodel

The same underlying model is used for SAG and ball milling, with minor differences for the way the charge density is calculated and whether the mill is a grate discharge (most of the SAG mills) or overflow discharge (typically a ball mill). Within the classification, there are also two versions of the Morrell Cmodel:

mill lines wear methoed

of the liner by 3D discrete element method (DEM) simulations of the ball charge in an axial slice of the mill, which is either closed by a periodic boundary condition or by frictionless end walls. The calibration of this wear data with the measured wear profiles of the shell liner in a m diameter industrial cement tube mill shows that

ball mill liner plate China HS code import tariff for ...

Latest China HS Code tariff for ball mill liner plate Tariff duty, regulations restrictions, landed cost calculator, customs data for ball mill liner plate in ETCN. China customs statistics trade data. ... Rolled products of stainless steel, of a width of 600mm or more,of a thickness exceeding 10mm,(not further worked than h...

Ball mill maintenance Prime Machine, Inc.

Ball Mill Maintenance Shop and Field work. Ball mill maintenance our shop and field crews make a unique combination to provide complete and up to date ball mill maintenance services. The shop is fully equipped with the large machining, fabrication, and engineering capabilities to rebuild your mill components. Our mechanics are experienced at removing and installing large bearings.

Mill and Scrubber Linings Multotec

Mill and Scrubber Linings 1. Shell Plates* The thickness of the Shell Plates can vary in order to increase mill capacity and/or liner life. The width is designed for optimum protection from the Lifter Bars. 3. Head Plates* Rubber Head Plates are available in various designs to combat sliding abrasion. Head Plates are designed to

.:. tools

tools Home Calculations Articles . Calculations. Millspeed Sliderule Pipe Launder Liner Height ... Estimates the critical speed of a grinding mill of a given diameter given the mill inside diameter and liner thickness. If given a measured mill rotation (RPM), then the mill`s fraction of the critical speed is .

corrugated ball mill liners plate

rock ball mill mineing equipment; quarrie mineral ball mill machine for sale; theater schedules mills ball mill; copper ore gold ore to ball mill; iron ore dressing ball mill rail runner size; tons of manganese ore ball mill; ore ball mill copper ore making machine ball mill; grinding ball mm; m gold ore grinding ball mill plant for rental at ...

Calculation Of Ball Mill Charge Volume

Ball mill charge becomes measurably swollen only when there is a buildup of large unground material in the ball mill or when the density of the pulp in a wet mill is extremely high. Although these conditions are seldom encountered, it is recommended that ball mills be ground out prior to shutdown for measurement of the charge level. Live Chat

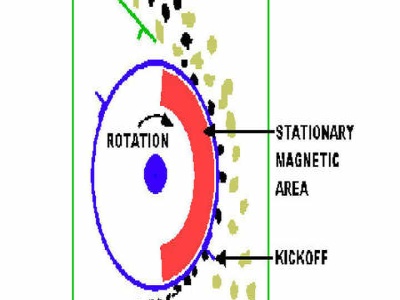

Performance enhancement tools for grinding mills SAIMM

PERFORMANCE ENHANCMENT TOOLS FOR GRINDING MILLS 105 By locating microphones near the mill on fixed positions and applying appropriate algorithms online to the microphone signals, impacts on mill liners can be isolated from mill noise, then classified and counted to provide a quantitative measure of their occurrence. The observed

how to measure ball mill area

Development of a method to measure charges in tumbling mills. Common Methods to Measure Tumbling Mills Charges ... Once found the mathematical descriptions of the circumference and the polynomial, the area ocupied by the ... In the ball mill, measurement by MCP resulted in a charge level of %. Get Price

the selection and design of mill liners_图文_百度文库

High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation.

Latest Posts

- عملية تعدين الذهب الغريني

- خام الحديد الفصل المغناطيسي معدات

- إنتاج مصنع كسارة الحجر على الإنترنت

- آلة غربلة آلة تلبيس خام الحديد

- سحق المحمول وفرز الجزائر

- تعدين الذهب معدات روبية 4 جدول للبيع

- عملية صنع الرمل الاصطناعي في المملكة العربية السعودية

- مصنع كسارة متنقل مستعمل في السعودية

- كسارات الصخور الصغيرة لبيع

- قدرة كسارة الحجر 30 طن في الساعة

- مطحنة الكرة اليمن للبيع

- مصنعي معدات التعدين في روسيا

- محطات كسارة متنقلة لخام النحاس

- المنغنيز معدات تجهيز

- الكوارتز الرمل آلة إنتاج

- s5x series screening equipment

- ppt for lhdc in coal conveyors

- price weill gyratory crushers bs

- por le gold track rock crusher

- crusher for sale used philippines

- crushing sale polyflex conveyor belts

- auto border grinding machine

- gold mainae india govt policy2015

- zenith 200tph stone crusher

- roller mill carbonate

- gravity concentrator used in gold ore extraction

- rock crusher 379 mar

- modern flour mills replace stone mills in egypt

- crusher plant dengan kapasitas 100 ton

- mp mets cone crusher