balance wet grinding mill

Wet or dry dressing of surface grinder wheel?

Jan 22, 2015· Think wet or dry not much different. I Like to dress wet when I have coolant and shut coolant off before shutting off spindle. Have seen out of balance wheels from shutting wet then standing off for a long time. Often the wheel might be scrap after that.

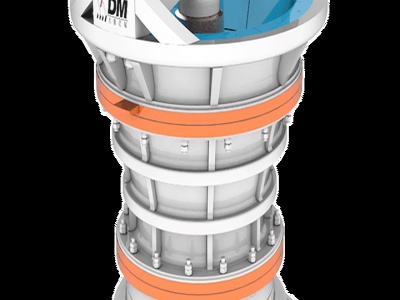

Tube Mill

Tube mill. Tube mills are used for wet grinding iron ore, gold/copper ore, nickel ore and other ores, as well as for grinding lime/limestone for flue gas desulphurisation systems, coal and other raw materials. Depending on the required product quality, wet grinding tube mills operate in .

heat balance wet ball mill mill

heat balance wet ball mill mill Motor Radiator Specification. Mining grinding ball mill/radiator tube mills energysaving wet type ball mill. US Set. 1 Set Min. Order. Luoyang Zhongde Heavy Industries. Get Price Nanbei Instrument Equipment lab instrument

Draiswerke: Wet Grinding/Dispersing Mills PCI Mag

Oct 03, 2000· Draiswerke: Wet Grinding/Dispersing Mills. October 3, 2000. Reprints No Comments The newest DCPMEGAFLOW C micro wet grinding/dispersing mills were designed for highflow recirculation grinding and dispersing, achieving the ultimate in fine grinding with narrow particle size distribution. New features include better grinding zones, a new design ...

Laboratory Grinding Mills Suppliers ThomasNet

Manufacturer of laboratory grinding mills. Micro mills for milling, mixing and dispersing of solids in liquids are available. Features include single phase motor, digital display, built in timer, stainless steel mixing element and shaft, adjustable quick fit clamping device and electronic safety ...

: 90 AHM wet mill

Wet mill 90 AHM. Horizontal agitated ball mill designed for the wet grinding of small to ultrasmall product batches down to the nano fineness range. The 90 AHM is the laboratory version of the AHM product line and is designed as a tabletop model with separate control unit. This mill is suitable for small amounts of product and for development ...

Problems in population balance modeling of wet grinding ...

The Population Balance Model, PBM, contains flaws making its use for effective simulation and control of milling circuits questionable. Presented is an analysis, based on published experimental wet grinding data, showing that the assumption of linearity, used in solving the PBM, is certainly wrong in many grinding mills and wrong for most commercial wet grinding circuits.

Mill (grinding) Wikipedia

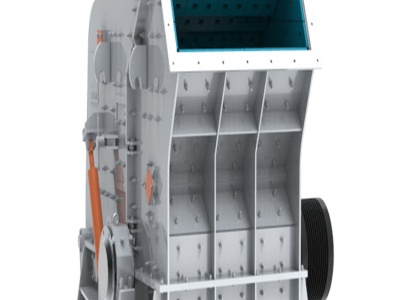

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Professional Three Roller Mill Precision Three Roll Mill ...

Product Description: Qualtech Products Industry Three Roller Mill is a production grinding machine at industrial scale designed and engineered for milling and wet grinding of a wide range of materials from medium to high professional Three Roller Mill finds its production application in the industrial fields of paints, inks, toners, lubricants, coating materials ...

Best Wet Grinder For Grinding Food Grains Into Pastes And ...

Jun 21, 2019· A wet grinder is a kitchen appliance made especially for turning soaked grains into the perfect consistency for making bread and cakes. The wet grinder consists of a drum containing several granite stones. As the stones rotate, they grind the grain between them to produce a batter or paste that is then used for cooking.

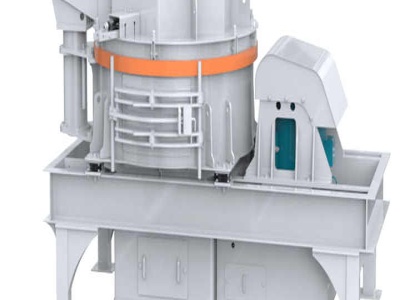

Outotec Grinding Mills Outotec

Grinding; Grinding Mills; Outotec Grinding Mills. Optimize grinding mill performance, efficiency, and availability to ensure you meet your plant's operational targets. Outotec highperformance grinding mills use advanced simulation tools for the best possible process efficiency, mechanical reliability, and .

Ball Mill Loading Wet Milling Paul O. Abbe

When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product. Charging a Wet Mill – The general operation of a grinding mill is to have the .

Wet Grinding Machines Mills

Bepex wet grinding machines are capable of handling the complete range of moisture levels. We have designed wet grinding mills to process vegetable and meat products, multiple wet and dry ingredients mixing, delumping and dissolving of fluids, slurries and pastes.

how wet grinding works in horizontal mills

WetGrinding Mills | SpringerLink In this chapter the mechanisms of wetgrinding mills are considered. The nature of the forces at work, together with a detailed consideration of their interplay and means of control, are discussed in Chapter 6. The general term "tumbling mill" includes the rod mill, pebble mill, and ball mill.

Investigation on the ultrafine grinding of coals based on ...

Request PDF on ResearchGate | Investigation on the ultrafine grinding of coals based on a Matrix Population Balance Model | The ultrafine grinding kinetic model for pulverized coal based on the ...

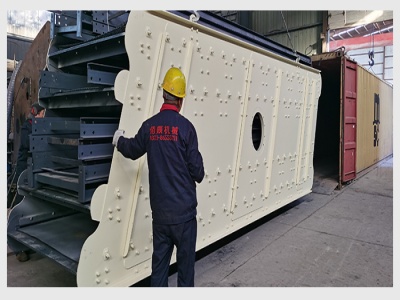

Practical Roll Techniques Grinding Balancing

Consistent grinding and balancing of rolls is necessary for efficient operation and optimum paper quality. As an integral part of a modern roll maintenance program, roll grinding and balancing uses machinery with accurate inspection and measurement equipment. This paper provides practical tips on roll inspections, balancing, grinding and grooving.

Corn Milling: Wet vs. Dry Milling

Corn wet milling and dry milling are the predominant methods of processing and each method produces distinct coproducts. The Corn WetMilling Process. The Corn wetmilling process is designed to extract the highest use and value from each component of the corn kernel. The process begins with the corn kernels being soaked in large tanks called ...

Ethanol Production Dry versus Wet Grind Processing

Ethanol Production Dry versus Wet Grind Processing Traditionally, ethanol from corn has primarily been produced through dry and wetmilling processes. The majority of ethanol production is from drygrind technology. The traditional drygrind process grinds the whole corn kernel and mixes it with water and enzymes.

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ...

MiniSeries / MicroSeries laboratory mills NETZSCH ...

MicroSeries. Finest wet grinding technology – the laboratory mills of the MicroSeries are an investment in the future for new product developments of different fields of application of pigmented ink jets, technical ceramics, cosmetics, pharmaceutical applications and nanoscale hightech products. The improved centrifugal separation system of the worldwide known peg grinding system Zeta ...

Wet Corn Milling Energy Guide

Corn wet milling is the most energy intensive industry within the food and kindred products group (SIC 20), using 15% of the energy in the entire food industry . After corn, energ y is the second largest operating cost for corn wet millers in the United States. A typical corn wet milling plant in .

Latest Posts

- أعلى 10 الكسارات النقالة العلامة التجارية

- مصانع تكسير الحجارة في الفجيرة

- إعدادات درجة حرارة الكسارة المخروطية

- الصين مخروط محطم أجزاء

- كسارة مخطط الحجر

- سحق الكروم الكيميائية الصف الأردن

- مصنع الثانوية كسارة الفك في المملكة العربية السعودية

- الذهب محمول مخروط خام محطم الصانع

- آلة كسارة مسحوق صغيرة

- بناء كسارة الصخور الفكية

- نوع حلقة من الصلب المطرقة مطحنة الكربون في المملكة المتحدة

- مطحنة الكرة kalong الهوائية تعقيمها

- قطع غيار كسارة فكية رائدة

- مخروط الصين المصنعين محطم الصين مخروط محطم

- انديست كسارة

- mobile conveyor 3d models

- crusher part jaw plate

- canada hearing aid clinics listenup canada

- sodium laureth mining

- philippines flour milling company

- understanding gravel crushing jan

- glass crusher machine in peru

- fluorite crusher joyal

- sale raymond roller

- photos of mobile crusher on tracks

- cost of building a tph coal preparation plant

- mike mills roll callcall

- excellent quality useful automatic furnace slag block machine

- formula for calculation of tph in cement mill

- complete used brick plants for sale