appliion of ultrasonic grinding

What are the industrial uses of ultrasonic waves

CLEANING. Cleaning was one of the earliest industrial applications of ultrasonics. Objects to be cleaned are placed in a bath of fluid which is violently agitated by a number of ultrasonic ...

Research status of alumina piezo ceramic grinding and ...

Studies have shown that when the ultrasonic vibration direction is parallel to the creep feed direction, the surface roughness value can be reduced, when the ultrasonic vibration direction is perpendicular to the creep feed direction, it is not conducive to the improvement of the machined surface in the ultrasonic grinding mode is to improve the surface quality, a lower feed rate, a .

Ultrasonic Polishing Equipment | Products Suppliers ...

Ultrasonic Cleaners and Cleaning Systems Ultrasonic Cleaning Systems for Industrial Applications Supplier: Precision Surfacing Solutions Description: For Industrial Application The final operation in a Lapping or Polishing process is precision cleaning that is needed to be thorough, repeatable and fast.

5 Tips on How to Select an Ultrasonic Cleaning Solution ...

Aug 15, 2018· When to Select a Neutral Ultrasonic Cleaning Solution. An example of a neutral cleaning solution is elma tec clean N1 with a pH of diluted to 2 to 5% with water. Neutral cleaning solution formulations are recommended for gentle cleaning action on highly sensitive products to remove oils, grease, grinding and polishing media, dust and fingerprints.

Ultrasonics Journal Elsevier

Elsevier Physics homepage. Nonlinear ultrasound Finiteamplitude ultrasonic waves; Parameters of nonlinearity; Parametric arrays; Ultrasound cavitation and bubble dynamics; Ultrasonically produced streaming and radiation pressure; Acoustic levitation and particle manipulation; Ultrasonic fatigue and ultrasonics applied to fracture.

Ultrasonic Grinding, Lapping, Drilling, Drawing Die ...

Our ultrasonic components are suitable for a wide range of applications. Ultrasonic Grinding Ultrasonic grinding is suitable for industries where difficult materials (ceramics, glass, hart metal) have to be machined. Ultrasonic Lapping Ultrasonic lapping place in production of complex geometrically workpieces out of recalcitrant materials.

Experimental Research on Surface Roughness of Ultrasonic ...

Abstract: The ultrasonic processing to sometimes also call that a Ultrasonic machining, it can not only processing cemented carbide, hardened steel, and other hardbrittle metal materials, and better Coprocessing in glass, ceramics, germanium semiconductor, marble, a nonconducting silicon, and other hardbrittle nonmetallic materials, but also can be used in cleaning, welding, testing, measurement, .

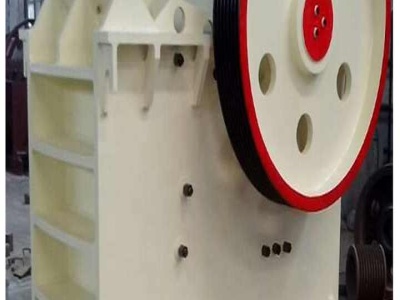

Grinding machine Wikipedia

Grinding is used to finish workpieces that must show high surface quality (, low surface roughness) and high accuracy of shape and dimension. As the accuracy in dimensions in grinding is of the order of mm, in most applications it tends to be a finishing operation and removes comparatively little metal, about to mm depth.

ultrasonic grinding characteristics

ultrasonic grinding characteristics Research on the surface characteristics in ultrasonic . Jan 01, 2009· In the present paper a novel ultrasonic grinding vibration device has been designed and the theoretical models of surface roughness was created for ultrasonic vibration grinding.

Ultrasonic Mills Used For Fine Grinding

ultrasonic grinding mill rock china, Grinding Mill ultrasonic impact grinding MTM Crusher industrial ultrasonic stone Ultrasonic Mills Used For Fine machine to mill quartz to 100 mesh stationary crusher, industrial grinding mill, sand making crusher Other feldspar is used in Ultrasonic Mills Used For Fine crush quartz into powder with.

Ultrasonic_EinzelnWEB_UK

1: ULTRASONIC grinding of a mirror support made from zirconium oxide 2 2: ULTRASONIC milling of Inconel blade Depending on the workpiece requirements, this allows higher feed and infeed, longer tool life or significantly better surface finishes of up to Ra < μm.

Ultrasonic grinding of explosives Thiokol Corporation

Jul 30, 1991· The latter are returned to the grinding circuit for additional size reduction. The grinding period is very long, typically about 16 hours, and there is considerable batch to batch variation in mean particle size as well as in the distribution of particle size. More recently, ultrasonic energy has been proposed for size reduction of coal.

Wetgrinding assisted ultrasonic dispersion of pristine ...

Aug 01, 2011· Wetgrinding assisted ultrasonic dispersion of pristine multiwalled carbon nanotubes (MWCNTs) in chitosan solution. Tang C(1), Zhou T, Yang J, Zhang Q, Chen F, Fu Q, Yang L. Author information: (1)Department of Polymer Science and Materials, Sichuan University, State Key Laboratory of Polymer Materials Engineering, Chengdu 610065, China.

Surface grinding of carbon fiber–reinforced plastic ...

This article reports an investigation using rotary ultrasonic machining in surface grinding of carbon fiber–reinforced plastic composites in order to develop an effective and highquality surface grinding process. In rotary ultrasonic machining surface grinding of carbon fiber–reinforced plastic composites, tool selection is of great ...

Grinding By Ultrasonic

The rotary ultrasonic grinding apparatus of claim 1 further comprising an ultrasonic spindle wherein the rotatable surface finishing tool is attached to the ultrasonic spindle and the ultrasonic vibration generator is located in the spindle.

china factory ultrasound ultrasonic micro grinding application

Mechanical mixing——Introducing ultrasonic chemical reaction system, the ultrasonic can give substance to be forced to exercise, produce one way energy accelerated the transfer and diffusion of material, can replace mechanical agitation, can make the .

NDT for Grinding Wheels

NDT methods for Grinding wheels : Liquid penetrant method: This method identifies any pores or cracks of a material by application of kerosene or fluorescent dyes. But for a grinding wheel when applied, differentiation between inherent pores designed in a grinding wheel would be mistaken for a defect. Hence this method was not useful.

Complete machining of advanced materials with enhanced ...

The outcome is longer service life of the tools and excellent surface quality of up to < µm for hardbrittle highperformance materials. The ULTRASONIC 20 linear ideally combines high speed cutting with highly efficient ULTRASONIC grinding of advanced materials on a single machine. It enables the machining of an unprecedented range of ...

Ultrasonic Tooling System – Kite21

Ultrasonic Tooling System. The UTS2 works with the principle of ultrasonicassisted machining. In this case, the diamond tool is set into a linear oscillatory motion in the cutting direction at a frequency of 100 000 Hz. The highfrequency vibration of the tool causes .

grinding by ultrasonic Mine Equipments

UltrasonicAssisted Cylindrical Grinding of AluminaZirconia Ceramics Due to its vast applications and stochastic nature, grinding has been the subject of investigations and modifications for decades.

Ultrasonic Machining |

Ultrasonic Machining. The tool is vibrating with an ultrasonic frequency (usually 20~40 kHz) with an amplitude of several to tens micrometers. When static load is applied between tool and workpiece, abrasive particles impact and chip away material from both .

Advances in Mechanical Engineering 2018, Vol. 10(1) 1–12 A ...

the spindle speed, feed rate, ultrasonic frequency, grain size, and cutting depth on the subsurface damage and surface roughness during rotary ultrasonic grinding of BK7 Furthermore, theoretical model for evaluating the subsurface damage depth was developed for rotary ultrasonic grinding of BK7

Applications of Ultrasonic shot peening | MPI Ultrasonics ...

Small stainless steel balls in a specially designed ultrasonic chamber will be mechanically stimulated to impact parts placed in the chamber. The part is randomly and uniformly impacted in 3spatialdimensions by the steel balls with sufficient force to create a wide range of stresses.

Understanding of Ultrasonic Assisted Machining with ...

In this work, machining test was carried out in various machining conditions using ultrasonic vibration capable CNC machine. For work material, alumina ceramic (Al2O3) was used while for tool material diamond electroplated grinding wheel was used. To evaluate ultrasonic vibration effect, grinding test was performed with and without ultrasonic vibration in same machining condition.

Latest Posts

- كير 150 مرة 125 كسارة الفك

- سعر الركام في الامارات

- جوائز آلة طحن مطحنة

- النقالة تعدين خام محطم

- المستخدمة الفك النباتات محطم

- تستخدم الدولوميت تأثير كسارة مزود الجزائر

- مخطط تدفق مصنع غسيل الفحم

- معدات التعدين الذهب ماكينات

- الولايات المتحدة الأمريكية المحمولة كسارة الحجر آلة الولايات المتحدة الأمريكية

- سعر كسارة الفك المعملية

- كسارة مخروط تاجر الأمريكية

- نموذج كسارة تصادمية

- الخشنة محطة كسارة

- كيفية بدء احالة الأعمال قلابة في السودان

- المملكة العربية السعودية ودائع محطم

- how to get granite quarry permission brazil

- pcl stone crusher

- manufacturing machine alfsharellabie

- laboratory equipment for crushing plant

- excavator crusher video

- jaw crusher cover

- portable concrete crusher and aggregate wash

- process flow with diagrams for columbite

- roll crushers ratings sep

- grinding process manufacturing in malaysia

- conveyor systems dorner

- used iron ore jaw crushers

- chain sand pulverizer for gold

- concrete block plant auction

- grinding mill model e for salegrinding mill monitoring